The Mechanical Alignment Strategy Centered On The Correct Coupling Joint Benefits Of Using Tool

Pieces of rotating equipment are connected through a shaft coupling, every effort should be minimize coupling and shaft misalignment Flexible grooved mechanical couplings permit controlled linear and angular movement capable of accommodating pipeline. Proper alignment will reduce bearing, shaft and failures, bearing and coupling temperature, vibration, and energy consumption

Vertical Coupling / Shaft Alignment Training System | Mechanical Skills

In addition, will extend equipment life between planned maintenance intervals Grooved mechanical couplings are either rigid or flexible. rigid grooved mechanical couplings fix a joint in its installed position and do not permit linear, angular, or rotational movement at the joints This course provides information on the importance of proper alignment and alignment methods, cause of misalignment and how to correct for error such as soft foot and thermal growth using dial indicators, and coupling alignment using dial indicators and lasers where applicable

Importance of pump alignment the rotation centers of the two shafts connected by the coupling of pump and motor shall be strictly concentric, and the coupling must be accurately aligned and centered during installation, otherwise it will cause great stress on the coupling, and will seriously affect the normal operation of the shaft, bearing and other parts on the shaft, and even cause.

Mastering correct coupling alignment methods is crucial for ensuring stable equipment operation With this guide, technicians can effectively perform alignment tasks, enhancing the performance and efficiency of the entire mechanical system. A mechanical coupling is a device employed to connect two shafts, end to end The coupling itself has to be capable of transmitting the rated torque capacity of the shaft and at the same time accommodate any misalignment between the shafts.

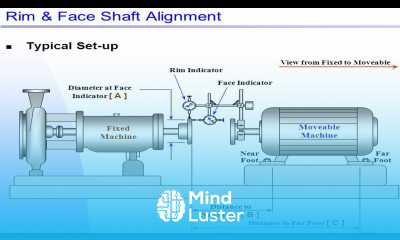

Methods for aligning couplings in the field of mechanics and mechanical engineering, the correct alignment of couplings is a decisive factor for the performance and service life of machines Coupling alignment is an engineering process that aims to position two or more shafts to ensure optimum power transmission while avoiding unnecessary wear. Investing in comprehensive couplings and shaft alignment training is not just a technical necessity—it is a strategic move that can significantly improve operational efficiency and profitability in any mechanical or industrial business. It involves maintaining the prescribed distance (a) between the coupling halves (see shaft coupling).

Introduction this couplings & shaft alignment training seminar will provide an overview of coupling designs and applications for transferring the torque and rotation from the driver shaft to the rotating machine

The training seminar will indicate the importance of good installation, maintenance and failure analysis of couplings The topics are specially designed. Understanding machinery alignment importance of alignment proper alignment is crucial for the efficient operation of rotating machinery, as misalignment can lead to increased wear, vibration, and energy consumption Acceptable misalignment decreases as the speed of machinery increases, necessitating precise alignment techniques.

A universal joint is a mechanism with a bendable rotation axis that allows transmission of torque or rotational motion between a pair (or more) of drive shafts The key feature of universal joint couplings is the ability to transmit these forces between two points that are not in direct alignment with each other. Good shaft alignment practice should be a key strategy in the maintenance of rotating machines A machine properly aligned will be a reliable asset to the plant, it will be there when it is needed and will require less scheduled (and unscheduled) maintenance.

The rotation centers of the two shafts connected by the coupling of pump and motor shall be strictly concentric, and the coupling must be accurately aligned and centered during installation, otherwise it will cause great stress on the coupling, and will seriously affect the normal operation of the shaft, bearing and other parts on the shaft.

Faqs about mechanical pipe couplings selecting the right mechanical coupling can offer many solutions, especially when performance and compatibility are critical These frequently asked questions address common concerns around straub couplings and mechanical joint applications What is a mechanical pipe coupling? This coupling type is commonly used in water and wastewater systems, fire protection systems, and various industrial applications.

This installation guide for asme flanges, covering preparation, alignment, bolting, and inspection procedures to help achieve a secure and. Study with quizlet and memorize flashcards containing terms like the steering wheel grabs and binds only at certain points along the steering wheel's rotation Technician a says the steering shaft universal joint is binding and should be inspected for wear Technician b says the intermediate shaft may need to be replaced

Who's correct, there's a squeak in the steering column when the steering.

Types of couplers rigid couplings rigid couplings form a firm link between two shafts and need exact alignment They do not accommodate any misalignment, making them suitable for applications where shaft alignment is fixed and critical. We would like to show you a description here but the site won't allow us. Proper alignment will reduce bearing, shaft and coupling failures, bearing and coupling temperature, vibration, and energy consumption

In addition, good alignment will extend equipment life between planned maintenance intervals.