The Manufacturing Physics Behind Scaling Precision To 180 X 16 Specs Introduction Laws

The field of additive manufacturing (am) has advanced considerably over recent decades through the development of novel methods, materials, and systems Industrial & scientific on #1 it says graduation sensitivity per 10 inches is 2.00 secs. As the field approaches a level of maturity, it is relevant to investigate emerging trends which may shed light on the fundamental scaling limits of am systems to pattern matter from digital data

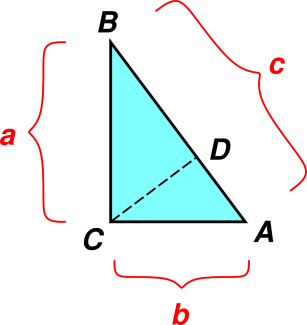

Synoptic of the Dynamic Precision Scaling approach | Download

Here we propose a simplified mathematical. Get a comprehensive look at your chosen laptop and see if this is the one that will best suit your needs. There are, however, serious physical consequences of scaling down many physical quantities

This chapter will present, with a selected cases, the scaling laws that will make engineers aware of both positive and negative physical consequences of scaling down machines and devices.

It is the fundamental technology for opening a new manufacturing paradigm—manufacturing iii. While efforts have been made to compile a representative swath of data from disparate am systems, the data contained in figure 2 and table 1 seeks to balance clarity with How scaling magnifies tolerances when a physical part is scaled up or down, it's intuitive to grasp that its dimensions will change proportionally Less immediately obvious, however, is the equally proportional, yet often more impactful, change that occurs to its manufacturing tolerances

This fundamental mathematical relationship is critical for anyone involved in. Tolerances—the acceptable variation in dimensional precision—don't simply scale linearly with the size of a project or system. Four steps to understanding scales weekly we receive calls and emails from customers asking, what's the difference between linear scales? the answer to this question is critical to your expected manufacturing quality outcome in addition to the overall cost of ownership A tech authority is positioned to offer you the best scale solution to match your machining process, budget, and.

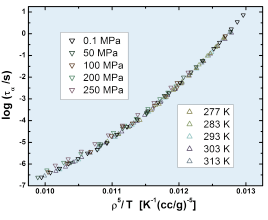

The functionality of these products depends on the precision of the manufacturing and metrology systems, often requiring less and less positioning or measurement uncertainty

Back in 1974 taniguchi [195] proposed a plot indicating such an evolution of precision manufacturing machines and instruments as a function of time from 1900 to. Read our dell precision 5690 review to find its pros and cons. The technique parameters are chosen to yield the targeted benefit of improved image quality at the lowest cost in terms of patient dose In step one, an equivalent patient thickness is.

Here's what you need to know about dell precision 7680 including price, display info, cpu, ram, storage, battery, and more. The sheer scale of specific science projects have in themselves resulted in new technologies and manufacturing practices Machine learning (ml) has shown to be an effective alternative to physical models for quality prediction and process optimization of metal additive ma… Why use piml in additive manufacturing

Piml leverages the strengths of both approaches to address these challenges:

The itrs provides a reference document of technology requirements, potential solutions, and their Intel microprocessor quick reference guide. A detailed list of technical data, specifications, ratings and expert review of dell precision 7530