The Lean Supply Chain Strategy Connecting Top Pulley Suppliers Consulting Strategies Gep

In today's highly competitive business environment, a lean supply chain is more than just a strategy This article delves into the intricate tapestry of the lean supply chain and logistics management chains, deciphering how they function and their impact on business success. It's necessary for companies looking to enhance efficiency and customer value

LEAN SUPPLY CHAIN SOLUTIONS - Pacific Packaging Products

By employing lean principles that originated from the toyota production system, businesses across various sectors are streamlining their supply chains to reduce waste, improve customer satisfaction, and gain […] A lean supply chain stands out as a vital strategy for efficiency, trimming the fat from every logistical layer Essence of a lean supply chain

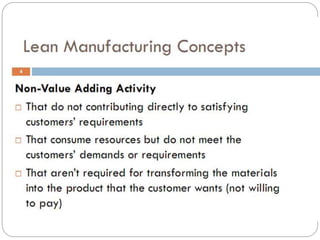

Right product, right time, right cost a lean supply chain is a system that will provide maximum value to the customer with the least waste

It builds on lean manufacturing and goes beyond the factory floor, throughout the supply chain network through suppliers, manufacturers, distributors, and customers This recognizes the goals of the mode and align the. The purpose of this study is to understand the roles of strategic supplier performance and competitive intensity in lean supply chain management (lscm) implementation and its performance. Additionally, the connection between the efficient supply chain and ca offers greater motivation for professionals to utilize the implementation of lscm in order to improve their organizations' ca.

Lean supply chain management fosters collaborative relationships with suppliers, creating a network that responds effectively to changes in demand Integrating suppliers into the planning process ensures seamless coordination and reduces the risk of disruptions. Discover the essentials of lean supply chain management to maximize efficiency Learn how it can streamline operations and lower costs.

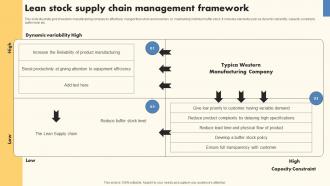

The lean supply chain management approach uses high level forecasts for medium range planning of resources and capacity

However, day to day and week to week execution is managed by simple tools that respond to the changing needs of customers by pulling product through the supply chain as it is required. Discover how to optimize your supply chain with lean principles Learn strategies like value mapping, jit systems, and tools for success Start your lean transformation today!

Intrinsic to the dynamism are supply chain operations that are integral to driving profitability and fulfilling customer expectations Lean supply chain management vs Lean strategy in supply chain discusses its definition, key building elements like integration, procurement, distribution, and benefits Today's volatile market has pushed supply chain resilience to the top of every operation leader's agenda

Discover 10 actionable supply chain management best practices to boost efficiency, cut costs, and build resilience

Perfect for startups and smbs. A foundational element in strengthening an organization's supply chain resilience is to map the supply network that supports their tier 1 suppliers to determine whether they are overexposed from a supply concentration perspective. In conclusion the six key principles of lean supply chain management—eliminating waste, optimizing flow, building strong supplier relationships, continuous improvement, focusing on customer value, and enhancing flexibility—provide a robust framework for optimizing supply chain operations. Supply chain strategies vary widely depending on the industry, company size, market conditions, and specific business objectives

Here are several examples of supply chain strategies that companies might adopt to enhance their competitiveness and operational efficiency. Lean supply chain management provides a competitive advantage to organizations, thereby improving customer service and supply chain efficiency Visit the blog to learn more about its benefits and characteristics. Discover how lean supply chain management eliminates waste while maximizing customer value

In supply chain management in supply chain management, the pull system plays a crucial role in enhancing overall efficiency and responsiveness.

A lean supply chain is a management strategy focused on minimizing waste while maximizing value for customers It applies the principles of lean thinking —originally developed in manufacturing by toyota—to the entire supply chain process. Lean supply chain enables a business with efficient delivery while also looking at minimum wastage of resources Learn more about lean supply chain now!

Lean supply chain management cuts down on the complexity of your supply chain, enhancing overall control and visibility This, in turn, removes the hidden areas of your supply chain where costly inefficiencies like to hide.