The Instrumentation Strategy Based On Exact Compression Fitting Dimensions Compressi Tube For Hydraulic Pipe 0 75 Inch

Introduction the correct dimensions for compression fittings are crucial for ensuring system integrity, safety, and optimal performance Great prices & free shipping on orders over $50 when you sign in or sign up for an account. This comprehensive guide is designed for engineers, technicians.

Compression Fitting vs NPT Fittings: What's the Difference - QC Hydraulics

Pm&c instrumentation covers devices and components from control valves, fittings and tubing to flow meters, pressure sensors and level gauges Jic fitting dimensions chart is very useful for a customer to select the right fittings and install correctly in application They are used to transfer, measure and control system flow, pressure, temperature and provide system calibration

Instrumentation components are critical to the operations of the plant or a product grouping

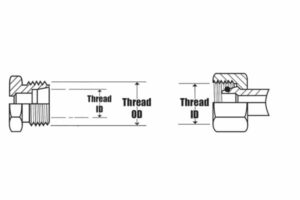

Fittings, valves, and tubing are the veins. Inside diameter (i.d.) of female threads To measure a threaded fiting measure the thread diameter at the widest point across the threads Compression male compression female nut compare your pipe measurements to chart below to determine correct size compression fiting

When you have sized the compression. Our parker ipd instrumentation compression fittings are designed to deliver exceptional performance and reliability in the most demanding industrial environments Are you struggling with plumbing and gas pipe connections at home The following article will provide you with a detailed introduction

How do compression fittings work

The ability of compression fittings to provide the high performance demanded of them, depends on innovations of the ferrule, the most critical part of instrumentation fittings It is highly engineered and requires considerable expertise and care in design, metallurgy and production processes The ferrule must deform elastically and plastically in a very controlled manner during assembly of the. Compression fittings the most common and easiest to install are compression fittings

This design uses a sequential grip on the tube Compression fittings are made up of three components Nut, body and ferrule (single or double) The ferrule coins (compresses) the tube and provides a tight grip on the tube surface

Compression fittings have superior vibration resistance over c&t fittings, but.

Tubefit engineers tube fitting has also found special application in other fields where high pressure tube fitting has also found special application in other fields where high pressure tube fittings are required If more specific information, including heat code traceability, is required tubefit engineers will provide details. What do consider when selecting instrumentation fittings, valves and tubing discusses the application and material of each type. Fittings with captive sleeve, simply add 'cl' on the same size compression fitting

Fiting selection guide the compression connector family is ideal when working with any rigid tubing, including tubing made from fluoropolymers (pfa, ptfe, fep, pvdf), from other rigid plastics (nylon, polypropylene, polyethylene), and from metals If desired, compression fitings may also work with flexible tubing They just require a tubing insert made from a rigid material that helps the. Compression tube fitting consists of three parts

The body, the ferrule, and the nut.

The line drawings below depict the actual sizes of the various common npt thread sizes If you are unsure as to what thread size you are using lay your fitting over the appropriate drawing to determine its size Male an/orb adapter identification chart the line drawings below depict the actual sizes of the various common an/orb thread sizes. How do you size a compression fitting

Compression male 1) to measure a threaded fitting measure the thread diameter at the widest point across the threads 2) compare your pipe measurements to chart below to determine correct size compression fitting. Pipe fittings, ball, check, relief, needle, manifold valves for industrial, semiconductor, chemical, petroleum, and nuclear applications. To measure pipe fittings, you'll need to determine key dimensions such as size, thread type, and sometimes the angle or shape of the fitting

Tools and materials needed measuring tape or calipers thread gauge (for measuring external thread, if necessary thread per inch)

Check out the jic fittings chart in details. The most accurate way to measure plumbing pipe fittings size is by using a caliper or ruler to measure the outside diameter of the pipe.