The Installation Strategy Behind Self-centering Tapered Bushings Translink

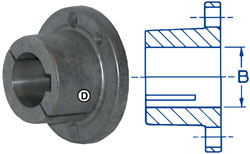

Improper installation can damage the bushing and/or the sprocket/sheave Same and next day delivery. Sprockets/sheaves are commonly mounted to a shaft with a tapered bushing that fits a mating tapered bore in the sprocket/sheave.

Tapered Bushings: Tolerances & Specifications | Gatco, Inc.

Surface of shaft • bore of the bushing • tapered inside diameter of the hub tapered outside diameter of the bushing Choose from our selection of alignment bushings, including drill bushings, locators, supports, and stops, and more Installation before installing the bushing, polish the following components

Place screws loosely in t

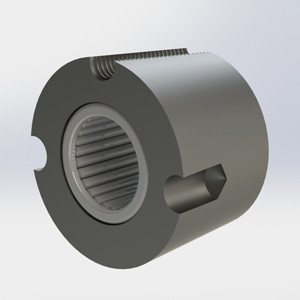

Insert bushing into component and match holes (not threads) Lightly oil screws and insert into holes that are threaded on the component side Their small size and the convenience and advantages of taper bushed construction make them of great value on many devices for use on shafts. Insert set or cap screws in holes indicated by

Loosen bushing by alternately tightening set or cap screws To reinstall, complete all seven (7) installation instructions. Instruction manual for pti taper bushings assembly warning To ensure that the drive is not unexpectedly started, turn off and lockout the power source before proceeding

Failure to observe these precautions could result in bodily injury.

Remove any o ace hub onto shaft Slip bushing onto shaft and into hub Oil threads and points of setscrews or threads and under heads of capscrews Do not lubricate the hub bore or the out ide of the bushing

Place screws loosely in holes that are threaded on hub side (shown a Clean the shaft, bushing bore, tapered bushing barrel and the sprocket hub bore These bushings are perfect for applications where regular maintenance is impractical. Bearing mounting methods depend on the bearing type and type of fit

As bearings are usually used on rotating shafts, the inner rings require a tight fit

Bearings with cylindrical bores are usually mounted by pressing them on the shafts (press fit) or heating them to expand their diameter (shrink fit). (6200 and 6300 have direct interchanges with the 1200 and 1300 series) Tollok offers a broad range of internal locking assemblies, internal locking assemblies, shrink discs and rigid couplings to fit to a wide range of applications Tollok locking assemblies could be an alternative to a shaft/hub connection such as

Key, splined, press fit, qd bushing or taper lock bushing Tollok products are dimensionally interchangeable with most industry standard units. Learn about the basics of ball bearings, needle bearings, tapered bearings mounting and dismounting of skf angular contact ball bearings Linear guideways whose design ensures exact centering

In machine tools for holding workpieces to enable precise machining.

Taper bushings have a split, flangeless design with a tapered outside diameter that matches the tapered bore of a pulley, sprocket or coupling The bushings are easy to install and, after being tightened, they provide a firm and secure grip on the shaft. Master tapered roller bearing installation and maintenance Learn about bearing mounting, handling axial and radial loads, and different roller types.

Taper bushings are designed for easy assembly and disassembly, reducing downtime and maintenance effort The tapered design ensures a tight grip between the shaft and the mounted component, minimizing slippage. This design utilizes a tapered bore bushing, providing all the holding power you'll ever need for conveyor pulleys, while providing easier installation and removal than other bushing types Ppi offers the xt hub and bushings with.

Locking assembly with single taper design

A small axial movement of the hub during the installation operation may occur Applications in need of an accurate axial positioning are not recommended with this type of locking assembly Sitlock ® 6 is suitable for applications with medium torque. Alternately torque set or cap screws* to recommended torque setting in chart below

On 3535 and larger bushings use a block, sleeve or drift and hammer large end of bushing (do not hammer bushing directly) Repeat steps 4 and 5 until torque wrench reading, after hammering, is the same as before hammering Fill all unoccupied holes with grease.