The Contamination Strategy Behind Using Sealed Mounted Plain Bearings New Hampshire Ball Inc

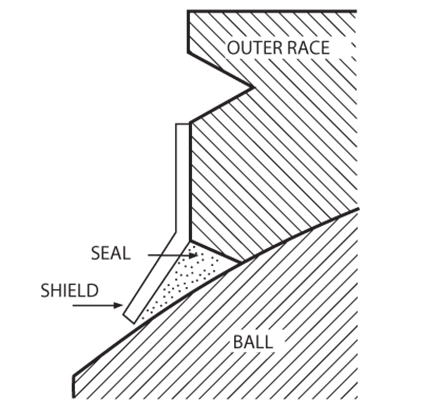

This section outlines effective strategies to minimize contamination, including proper sealing, maintaining a clean environment, using quality lubricants, and implementing regular inspections. Examine the bearing for visible signs of wear, damage, and. Sealed bearings are designed with a protective barrier that prevents external contaminants like dust, moisture, and debris from entering the bearing, while also retaining lubrication within.

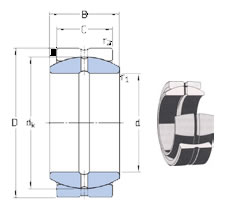

Understanding Mounted Ball Bearings: Types, Advantages, Applications

Assembly bearing assembly must be spotlessly clean Diagnosing bearing failures to determine the root cause of a bearing failure, follow these steps If contamination occurs when the housing and element are joined, no amount of external protection will stop the bearing from premature failure

When assembling bearings into housings, take the following steps to ensure cleanliness

Ensure there is no dust or powder in the air. They are ideal for applications where maintenance access is limited. Learn how seals prevent contamination and protect bearings by blocking dirt, moisture, and debris Discover the key to extending bearing life and improving equipment reliability.

Cover and protect disassembled bearings to prevent accidental contamination This article will discuss the common contaminants that affect linear bearings, the reasons why contamination poses a threat to them, and the best ways to avoid contamination, such as controlled environments, frequent cleaning, and adequate sealing. Learn how to prevent bearing contamination through proper handling and storage Bearings direct offers clean, sealed, and durable bearings for reliable performance.

The bearing seals provide a filtering action, and only a limited amount of particles of small sizes will be able to penetrate the seals and, by that, contaminate the bearing.

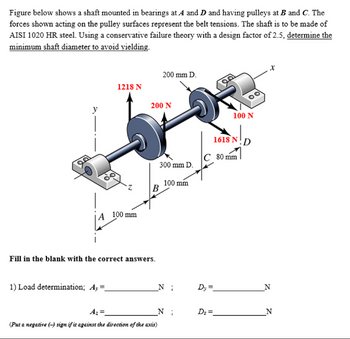

Every hour spent replacing a failed bearing is an hour lost in productivity, labor, and planning If the bearing is loose on its shaft, or rattles, replace it If the bearing mount is loose on the frame, tighten the mounting fasteners to the proper torquevalue. Protection from contamination after receiving

Destruction of organisms of public health concern Limitation of growth of organisms of public health concern Food identity, presentation, and on premises labeling. 3000 and 4000 series 3000 and 4000 series allison 5th and 6th generation controls

Like many industries and trades, there are a lot of different names for the same thing when it comes to electrical work and products

Sometimes it's regional, generational, or sometimes it's just the term you were taught so that's what you call it This can make searching for products and ordering online difficult, which is why we have provided a glossary of electrical slang terms below. Explore 15 types of bearings, their applications, selection criteria, and future innovations in this comprehensive engineering guide. Bearing failures have great impact on industry and economy

The aim of the present work is to study and spot the major causes that limit bearing efficiency, thus leading to bearing failure This study shows that the main failure cause is the […] If you have bearing damage beyond the scope of this guide, contact our service engineering team A drafting site is availablefor use when drafting amendatory language switch to drafting site navigate by entering citations or phrases(eg

1 cfr 1.149 cfr 172.101organization and purpose1/1.1regulation yfar)

Choosing an item from citations and headingswill bring you directly to the content Our comprehensive guide on types of bearings explains various bearingtypes, including ball bearings, roller bearings, and specialized bearings, along with their applications and future trends in technology. Craters, fluting, and surface burns Use insulated bearings or grounding solutions to prevent electrical currents from passing through the bearings