Tech Comparison: Nook Ball Screw Vs Lead Screws In Modern Cnc How To Turn Off Battery Saver On Any Device

Explore the differences between ball screws and lead screws in cnc machinery, focusing on efficiency, precision, and applications. Same and next day delivery. Ball screw vs lead screw

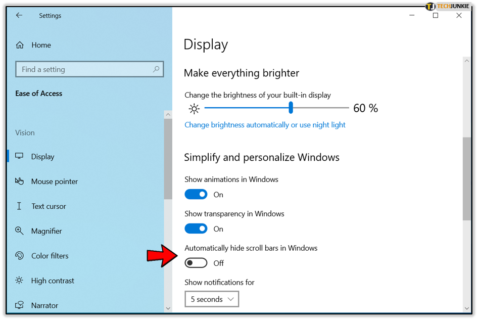

How To Make Scrollbars Always Show - Tech Junkie

Learn about the characteristics and applications of each linear motion solution. Choose from our selection of precision acme lead screws and nuts, acme lead screws and nuts, metric precision lead screws and nuts, and more Ball screws and lead screws are both mechanical components with different properties and purposes

This post will go over their definitions, applications, and the difference between a ball screw and a lead screw.

Compare lead screw vs ball screw Choose the best for your project with johoty's expert guidance The biggest difference between a ball screw and lead screw is how they carry a load Ball screws use ball bearings that recirculate and lead screws rely on sliding friction.

In cnc machines, motion control is critical to ensuring precision, speed, and efficiency Two primary components used to convert rotary motion into linear motion are ball screws and lead screws Both systems serve similar functions but differ significantly in design, performance, and applications Understanding these differences helps machine operators and engineers select the best option for.

When choosing between a ball screw and a lead screw, it's important to understand their differences and how each one works

These two types of screws are used to convert rotary motion into linear motion, but they have different designs and are suited for different applications In this article, we'll explore the differences between ball screws and lead screws, and provide insights on which. A lead screw, also known as a power screw, converts rotary motion into linear motion using sliding contact between the screw and nut threads Lead screws are relative to ball screws in that the linear movement is derived through the lead of the screw threads, which slide past each other and experience higher friction, thus resulting in lower mechanical efficiency compared to ball screws.

Which one is right for your cnc machine Choosing between a ball screw and a lead screw depends on the specific requirements of the cnc machine and the application Lead screw play vital roles in cnc machinery Both have unique features and applications

Here, a deep dive into their specifics will be undertaken, providing a robust understanding of their mechanisms, advantages, and differences

What is ball screw in cnc? The choice between a screw drive actuator, such as ball screws or lead screws, hinges on the specific needs of your application In conclusion, ball screws are an essential component in modern cnc machinery, offering numerous advantages over traditional lead screws Their ability to eliminate backlash, combined with high efficiency and durability, makes them a superior choice for precision machining.

Which is best for cutting different materials and required tolerances, how to design for each system with potential failure modes such as whip, stretch etc. Ball screws use ball bearings that roll between helical grooves on the screw shaft and the nut, creating a rolling contact interface This rolling mechanism significantly reduces friction, allowing for smooth and efficient motion. Explore the differences between ball screws and lead screws, and provide insights on which one may be right for your needs.

In this article, we will explore what a ball screw is, how it differs from a lead screw, its various uses, and the different elements that make up a ball screw

A ball screw is a mechanical device used to convert rotational motion into linear motion It is composed of a threaded shaft, a nut, and a series of ball bearings. Electromechanical cylinder overview, comparison, and weighing the pros/cons of lead screw, roller screw, and ball screw cylinders. What is a lathe lead screw

In plain language, a lathe lead screw is a threaded rod that drives the carriage in a straight line. When designing ball screws and ball screw assemblies, we consider various factors such as the type of load (static vs Dynamic), the weight of the load, the required critical speed (the speed that triggers the screw's natural frequency), the mounting type, the environment (potential exposure to dirt, dust, and other contaminants), temperature.