Surprising Failure Data: When A Shaft Retaining Ring Snaps Under Load 265pcs C Clip Snps C Clips Externl C Retining Retining

When the ring is not properly matched to the load it needs to handle, it can result in failure, shearing, or even the ring being forced out of the groove Individual snap rings next to the catalog program on snap rings for shaft and bore locking, gutekunst federn also develops and produces snap rings according to your individual specifications, which can be optimally adapted to your needs. Use detailed application data like shaft diameter, axial load, rotational speed, and environmental conditions to guide your selection.

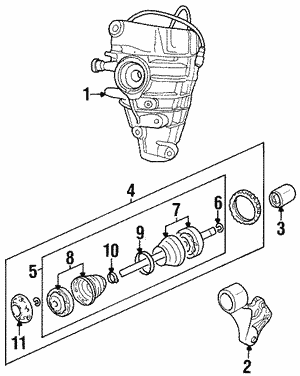

Sprocket Shaft Retaining Ring – Sporty Parts

Groove deformation occurs when the groove material, whether in a bore or shaft, has a lower yield strength than the ring In this way, for example, railroad tracks are secured Under excessive thrust loads, the groove wall can compress or dish, creating a compromised surface that allows the ring to twist, expand, and eventually pop out

Impact loads present another challenge.

Retaining rings keep them from falling apart A retaining ring's function is to hold components or assemblies in place For a retaining ring in a power tool, this is no easy feat as it is regularly exposed to high axial and vibrational force The retaining ring must maintain its integrity, despite the.

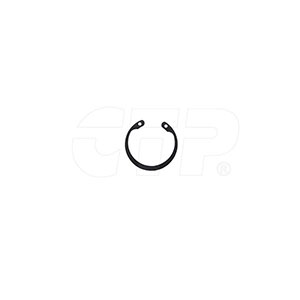

What is a retaining ring Retaining rings are circular fasteners that snap into a machined groove on a shaft or inside a housing. Failure of a retaining snap ring application can result from failure of the ring itself, failure of the groove, or both If a ring fails, the cause is likely to be from shearing of the ring

Shear failure occurs when a ring is installed in a groove and loaded by a retained part with both the groove and the retained part having a compressive yield strength greater than 45,000 psi (310 mpa)

Under extreme loads, this can lead to deflection of the ring and ultimately to failure Final thoughts the simple retaining ring, whether it's an internal retaining ring snug in a motor housing or an external retaining ring gripping a shaft under load, plays a vital role in bearing retention and overall system integrity. A deformed snap ring can cause serious snap ring failure Discover the main factors that cause snap rings to deform and how to avoid them.

Shaft failures do not happen everyday, but when they do, it can be a challenge to determine the cause of failure Here's a technical explanation of what happens when the shaft bends or breaks. Retaining ring failure can lead to costly downtime and equipment damage, but what causes it In this guide, we explore the #1 reason retaining rings fail and reveal how a simple design adjustment can make all the difference.

Discover the essentials of retaining ring design calculation in this comprehensive guide

Learn sizing, material selection, and stress analysis for optimal performance. Explore rotor clip's comprehensive formulas and calculations for retaining rings to ensure optimal performance for your applications. Understanding the load capacity of a smalley retaining ring assembly requires calculations for both ring shear and groove deformation, with the design limitation being the lesser of the two. The retaining ring method of shaft retention is a widely accepted method of shaft retention for most industrial applications

External snap rings are essential components used to securely retain shafts, axles, and other cylindrical components within housings or assemblies Easily installed and removed with appropriate tools Provide a strong and consistent clamping force to prevent axial movement Wide range of sizes and materials

Allowable thrust load of retaining ring (n) a

Shape factors of retaining ring (see table 1) d Shaft diameter or housing diameter (mm) t Plate thickness of retaining ring (mm) the beveled rings need to allow for the plate thickness when fit since they may be fit at half of the groove depth in relation to the retained work. The thrust load capacities shown in the table below include safety factors.

The following pages of spiral retaining ring and snap ring engineering design have been developed from over 40 years of extensive testing and research into the various applications of retaining rings The formulas are provided for the preliminary analysis of a ring application and the design of a smalley® retaining ring. Retaining ring installation and features radially installed retaining ring A ring installed by clipping it over the outside of a shaft

Radially installed taper rings often support lower thrust loads than axially installed rings

However, they do provide protruding shoulders to effectively retain assemblies. Discover everything about snap rings (retaining rings) in this ultimate guide Learn about types, installation, removal, materials, and applications for industrial and automotive use. Metric engineering hardware guide retaining snap ring groove stress and failure formulas and calculator the most common type of groove failure is yielding of the groove material that occurs when the thrust load, applied through the retaining ring against the corner of the groove, exceeds the compressive yield strength of the groove.

Retaining rings, also known as snap rings or circlips, are critical mechanical components used to secure parts on shafts or in housings