Snap Ring Types: 2026 Fatigue Analysis For High-speed Engine Safety Strain Process Download Scientific Diagram

Discover the essentials of retaining ring design calculation in this comprehensive guide Under these conditions, the ring would buckle, possibly leading to catastrophic failure. Learn sizing, material selection, and stress analysis for optimal performance.

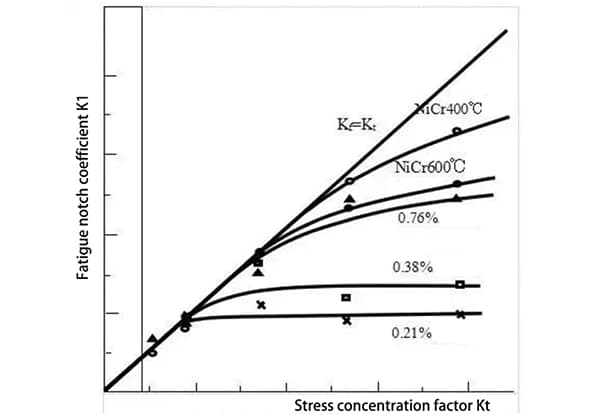

Stress-fatigue analysis process. | Download Scientific Diagram

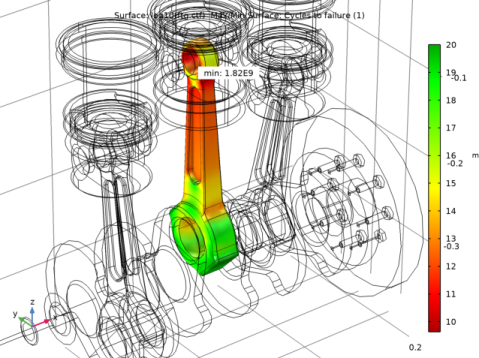

Get expert insights into the world of snap rings, covering design principles, selection criteria, and application best practices for optimal mechanical system performance. When loaded, the high stress region extends over the entire groove wall to the end of the shaft (or housing) and the groove wall actually distorts The fatigue life distribution of fatigue life analysis and the stress distribution of static mechanical analysis shows same regular pattern at same cross section.

Discover everything about snap rings (retaining rings) in this ultimate guide

Learn about types, installation, removal, materials, and applications for industrial and automotive use. The following pages of spiral retaining ring and snap ring engineering design have been developed from over 40 years of extensive testing and research into the various applications of retaining rings The formulas are provided for the preliminary analysis of a ring application and the design of a smalley® retaining ring. How do different types of retaining rings and snap rings vary in terms of their applications

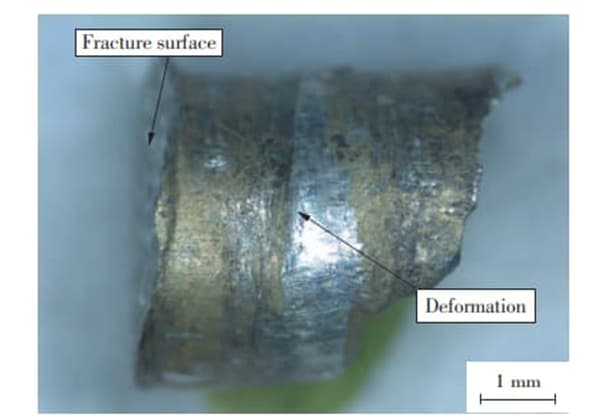

Different types of retaining rings and snap rings vary in their applications based on their design and functionality. Failure of a retaining snap ring application can result from failure of the ring itself, failure of the groove, or both If a ring fails, the cause is likely to be from shearing of the ring Shear failure occurs when a ring is installed in a groove and loaded by a retained part with both the groove and the retained part having a compressive yield strength greater than 45,000 psi (310 mpa)

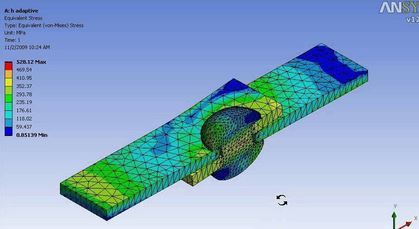

Snap ring | static structural analysis i deformation | stress | strain | fos | ansys workbench this video shows how to analyze a snap ring for deformation, stress, strain and safety factor using.

The most common type of groove failure is yielding of the groove material that occurs when the thrust load, applied through the retaining ring against the corner of the groove, exceeds the compressive yield strength of the groove This yielding of the groove results from a low compressive yield strength of the groove material, and allows the ring to tilt and come out of the groove, moment. Types of fatigue fatigue can be grouped into two classes High cycle fatigue and low cycle fatigue

Retaining rings, also referred to as snap rings, primarily provide shoulders to locate or retain parts on shafts or in cylinders Advantages of retaining rings are their economy of manufacture, ease of assembly and accuracy of positioning as compared to threaded fasteners. We're on a journey to advance and democratize artificial intelligence through open source and open science. Ansi mechanical hardware retaining rings are used to act as a mechanical stop or limit movement or to retain another part on a shaft or within a cylinder

Stamped retaining rings, also called snap rings are manufactured (stamped) from flat sheet stock.

Historic church in netherlands burns to ground Peace on paper, fire on the ground From installation to specifications to types and tools, our retaining ring guide covers everything Learn how to choose the ideal retaining ring for any application!

Bowed retaining rings bowed rings can come in internal or external styles These are curved versions of standard retaining rings which act like a spring This type of a curved design allows for a tighter hold Various styles available in internal or external.

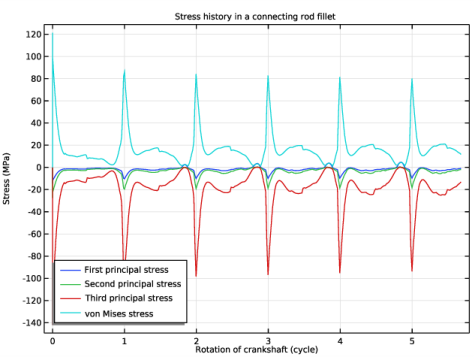

A guide to fatigue analysis this guide starts from the applications of fatigue analysis and its role in fea simulation

Fundamental concepts and principles will be introduced such as what is fatigue, fatigue design philosophy, life estimation methods, stress life approach, etc. Standard spirolox® retaining rings are available in carbon steel, 302 and 316 stainless steel, while constant section ring (snap rings) and hoopsters are available in carbon steel and 302 stainless steel Retaining rings can be produced in a variety of custom materials to meet unique environmental conditions. A comprehensive guide retaining rings, unassuming but critical components in the world of engineering and mechanics, come in various forms, each with its unique characteristics and advantages

Whether it's an internal or external, spiral, tapered or constant section ring, they are an essential component in an assembly and selecting the right style and. Finite element analysis shows stress gradients for a retaining rings in an application with insufficient edge margin