Pressure Data: Why A Single Transmission O Ring Failure Costs Millions 12 Cmmn Filure Issues Nd Slutins Hydrflu Hydrulic C

At precision polymer engineering, we have spent decades developing innovative elastomer materials able to resist the most challenging sealing environments Here's a breakdown of common causes:♦ physical damage during installation:1 The failure lived in the gap between a passed test and a controlled supply chain

News | Zatkoff

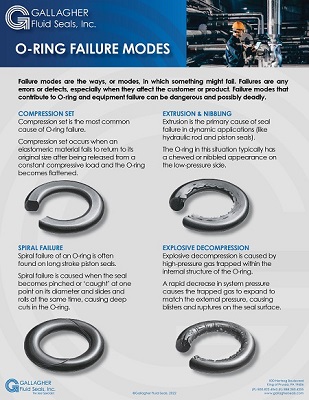

By understanding the root causes of failure and applying preventative measures, you can maximize uptime, reduce costs, and ensure reliable performance In this case, the o‑ring was extruding in both directions which told us that they had a gland overfill problem. Understanding the causes of o ring failure is essential for avoiding costly repairs, downtime, and potential.

Below, we break down what is most commonly seen on failed o.

Backup ring materials include buna (nbr), viton® (fkm), ptfe, peek, and nylon. Explore math with our beautiful, free online graphing calculator Graph functions, plot points, visualize algebraic equations, add sliders, animate graphs, and more. Another common failure mode that a customer had was a chewed up o‑ring, but they weren't running at a high enough pressure to really cause extrusion