Precision Data: Why Your 6mm Key Stock Tolerance Must Be Sub-micron What Is And How Is It Made?

How tight can machining tolerances really get Miki pulley top > services > technical documents > parallel key and keyway sizes and tolerances Learn how to get the right fit between keystock and keyways by understanding key terms like tolerance, fits, and fit classes in this introductory guide

Why Your Fresh Produce Business Needs a Specialized Produce ERP

Discover essential insights on machining tolerances in manufacturing Discover the micron precision seater die series by bullet central, offering unmatched accuracy and reliability in your reloading process, trusted by top rifle competitors worldwide. Learn how to achieve precision and quality in your projects

Discover why tight machining tolerances matter in cnc manufacturing

Learn how microns impact precision, part performance, and production costs. Why microns matterances are achieved in cnc precision machining for sectors requiring exceptional accuracy. Learn what tolerances in precision engineering are, why they matter, and how to manage them to improve manufacturing accuracy and product performance. Tolerance management for precision manufacturing is vital to ensure proper fit between parts and function correctly, especially when components are produced in different locations or by different suppliers

Tolerance standards allow manufacturers to control the allowable variation in part dimensions, ensuring reliable fits, proper assembly, and optimal performance across industries such as. What are standard tolerances for cnc machining in millimeters Standard tolerance for cnc machining is ±0.13 mm (±0.005″) for most milling and turning operations This precision level represents the baseline capability of modern cnc equipment and provides sufficient accuracy for most general applications without requiring specialized processes or equipment

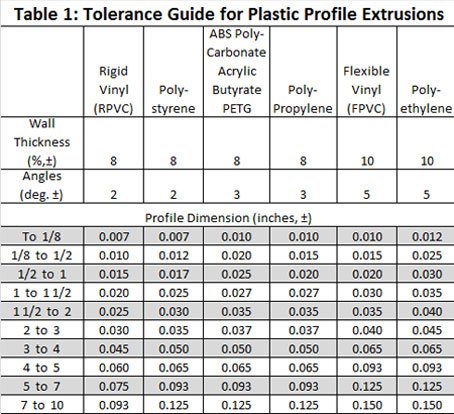

The table below provides a.

Understanding tolerances in precision grinding What you need to know about achieving tight tolerances, maintaining dimensional accuracy, and ensuring precision in manufacturing Learn how material selection, machine setup, and quality control impact grinding tolerances across industries. Special attention must also be paid to the selection of the gage and readout as well as to mastering

Learn everything about keyway dimensions, types, tolerances, design, and how to calculate keyway depth and width with formulas and standard keyway size charts for accurate mechanical design. One is a close, plus toleranced key stock and the other is a broad, negative toleranced bar stock Each is combined with appropriate keyseat tolerances to make assemblies. Let cheetah precision machining tackle your tightest tolerance needs modern precision machining capabilities now extend well into the micron tolerance range needed for medical devices and aerospace parts.

When it comes to 6 mm key stock, you can count on grainger

Supplies and solutions for every industry, plus easy ordering, fast delivery and 24/7 customer support. Specifications for key stock home » technical pages » product specifications » specifications for key stock Choose from our selection of grade 4140 steel in a wide range of styles and sizes Same and next day delivery.

Determine clearance, transition and interference fits, limits and deviations with schematic representation.