Movement Data: Why Hose And Conveyor Integration Speeds Up Unloading Free Images Silhouette Bridge Dance Color Foot In The Evening

Struggling with labor costs, safety risks, and inefficiencies at your distribution facility's dock By automating the movement of goods, roller conveyors reduce the need for manual labor, cutting down on labor costs. Learn how inbound sortation automation and advanced conveyor systems can transform unloading, boost efficiency, and overcome the toughest operational challenges in distribution and logistics.

flow Archives | Movement Training

Conveyor system integration is the backbone of modern fulfillment, and conveyor system integration done right can unlock major wins in throughput, accuracy, and labor efficiency. Roller conveyors significantly speed up the unloading process, allowing more goods to be processed in less time There are many ways to transport products vertically in a warehouse or manufacturing operation, each with its distinctive advantages and limitations

Vertical conveyors are one of the most common methods for certain loads and situations

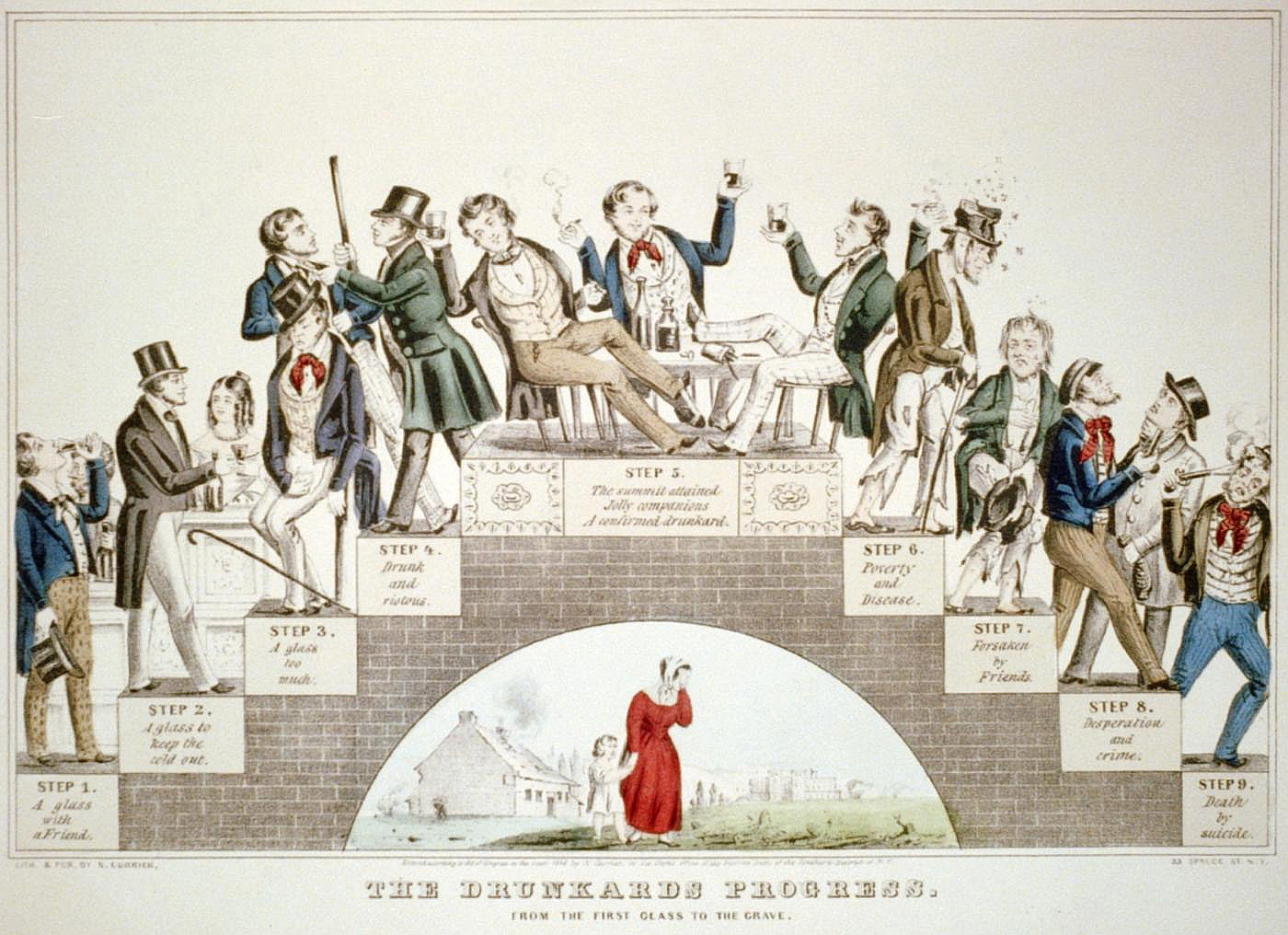

What are some of the integration factors. Why loading and unloading setups cause the largest visible bottlenecks loading and unloading warehouse operations sit at the handoff between inbound/outbound vehicles and the internal material flow Yet they are treated as a collection of discrete problems (dock design, forklift staging, conveyor speed) rather than a single throughput system. These technologies provide valuable data that can be used to identify bottlenecks, predict maintenance needs, and optimize resource allocation.

In conclusion, the integration of boom conveyors into warehouse operations is more than just a convenience, it's a strategic move that can significantly enhance the speed and efficiency of the unloading process. However, for autonomous transport to be fully realized, loading and unloading processes at shipping and receiving facilities must also be automated This paper takes a systems approach to identify the challenges and requirements for automated loading and unloading in a setting of autonomous truck transport potentially within a production setting. This integration allows for better synchronization of loading and unloading activities with inventory levels, transportation scheduling, and demand forecasting

For example, as trucks arrive, the system can automatically prepare for unloading procedures by adjusting conveyor speed or directing items to specific zones based on priority.

Separating inbound and outbound traffic routes minimizes congestion and reduces the risk of accidents Properly positioning loading docks and fire pump houses ensures convenient access for trucks and emergency equipment, which speeds up the loading and unloading processes and enhances safety and security. Discover the features, types, benefits, and applications of container loading and unloading conveyors, essential for optimizing material handling operations across various industries. What are some of the integration factors for these conveyors, and how can you handle them

Floveyor container unloading systems cater to a wide array of industrial needs, from food processing to chemicals, with speed, safety and reliability. The robot identifies the position of each item on the pallet, carefully picks it up, and deposits it in the desired location for further processing or shipping This automation reduces the need for manual labor, speeds up unloading times, and ensures consistent handling quality. Manufacturing and distribution centers conveyors streamline the movement of finished products from production lines to shipping containers

.jpg)

Technological advancements in conveyor systems automation integration

Modern conveyors can integrate with automated systems, such as robotic arms and guided vehicles, to enhance workflow. The unsung hero behind this seamless operation is the conveyor system, a key player in ensuring speed and efficiency from behind the scenes What is a conveyor system A conveyor system, in its essence, is mechanical handling equipment that moves materials from point a to b

But it is not just about movement, but about making life easier. All of our telescopic conveyors feature a vfd controlled belt drive system providing smooth transitions from belt starts and stops at speeds up to 120 fpm They also include a vfd controlled extension drive providing smooth operation when extending and retracting the conveyor. Customize your conveyor with hydraulic lifts, motorized or.

This article will explore the technical principles, key functions, and profound impact of intelligent monitoring and data analysis applications for conveyors in enhancing operational efficiency.

Use pneumatic railcar unloading to achieve faster rates, less downtime, and superior dust control Save time and money the pneumatic way. Loading and unloading workers loading and unloading materials should be instructed in safe procedures appropriate to the material they handle Truck or rail tank car loading or the unloading of flammable/combustible liquids is one of the most hazardous operations likely to be undertaken at any manufacturing or storage facility

Loading/unloading container conveyors were designed for loading and unloading roll containers into or from a container conveyor system They focus on determining the operational cost parameters for the following activities Loading and unloading, movement to and from storage, and order filling Yet, the costs of operations for preparing the cargo for loading and/or unloading are not covered in their parameter simulation.

Automated conveyor systems offer significant advantages over manual systems, such as faster speeds, higher throughput, and integration with other automated equipment, although they may come with higher upfront costs

A conveyor system is a mechanical device used to move materials from one location to another efficiently.