Leakage Data: Why A Radial Lip Seal Fails In High-pressure Systems Selg System Rdil Sel With Shft Nd Fluid Rdil Sel

The sealing products industry is committed to providing functional, efficient radial lip seals for all applications Wondering why seals keep failing in your system If a sealing system leaks, it is most important that the manufacturer be provided with as much data about the sealing system and its environment as possible in order to provide a timely and correct solution.

Intella 005948168 SEAL - RADIAL LIP

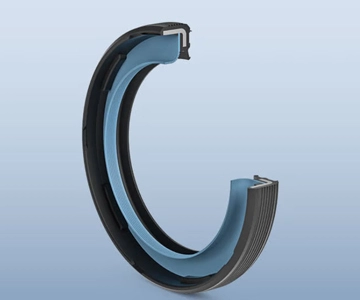

The typical lip seal structure is shown in figure 1 Seal failure isn't just inconvenient—it's expensive Leakage is the primary manifestation of seal failure, but the cause of leakage is not a single one

It is more due to the combined effect of multiple factors

If you want to understand […] The optimized lip seal yields an impressive 14.3% reduction in leakage rate compared to the original configuration, showcasing a significant performance enhancement in lip seal Rotary lip seal high speed rotation frictional heat contact pressure leakage failure Meanwhile, a high fluid pressure differential can significantly increase the radial force at the sealing lip, leading to thinning or even rupture of the lubrication film, thereby increasing the risk of leakage.

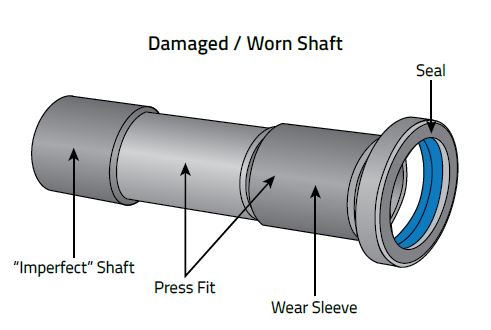

(2008) investigated the effect of surface roughness on the sealing performance of rotary shaft seals In view of such literature, the objective of this study is to investigate the effects of radial interference on the lifetime of the lip seal element, experimentally. The purpose of this article is to provide general guidelines for what may cause leakage or failure of an elastomeric radial shaft seal based on visual inspection of the failed seal. Additionally, the trend in component downsizing, including for sealing systems has indirectly altered the leakage behaviour of transmissions.

Chapter 8 failure analysis 8.1 sealing system leakage analysis chart lip wear eccentric wear tears in lip area lip damage seal distort high internal pressure

This can impair the function of the sealing system and ultimately lead to leakage This work, carried out within the aif research project welleneinlauf (wear of counter faces) [1], shows methods to identify and predict excessive wear of radial lip sealing systems based on their wetting properties and pumping rate. The document is a guide for the selection of radial lip seals It is designed to highlight the elements of a radial lip sealing system and assist in the proper specification of the element parameters.

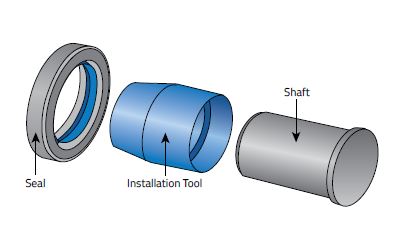

Lip seals are an important part of modern industries, where they help contain lubricants, keep contaminants at bay, and prevent leakage This guide will cover all the essential details about lip seals, from discussing their function to common types and how to install one yourself How does a lip seal function With such a high population of critical component seals and technology enabling seals worldwide, a modern contextual review of the physical meaning of seal leakage, underlying theoretical governing formulas, typical (order of magnitude) leakage values and trends of different seal designs, and the effective limits of seal leakage is more than warranted

The intention here is to create a.

Learn what a lip seal is, how it works, and the different lip seal types used in industries Discover the benefits, applications, and maintenance tips. Part 1—seal leakage and leakage management seal leakage there is always a mass flow rate across the face of a mechanical seal, so all seals leak to some extent Some seals, particularly noncontacting seals, are designed to have a certain flow between the faces.

Lip seals are defined as sealing devices designed to prevent leakage and minimize friction between moving parts, such as valve stems in engines, by balancing film thickness and lubrication efficiency They typically feature sharp or stepped lips to maintain low leakage rates under varying pressure conditions. It may be a device to join systems or mechanisms together by preventing leakage (e.g., in a plumbing system), containing pressure, or excluding contamination. As machinery becomes more advanced, mastering radial shaft seal design will remain essential for achieving operational reliability and extended service life.

Lip seal is an efficient and reliable dynamic sealing technology, which is widely used in various mechanical equipment

By understanding the principles, types, characteristics and application scenarios of lip seals, you can better select and use lip seals, improve the sealing effect of the equipment, and extend the service life of the equipment. The oil seal manufacturing industry is committed to providing functional, efficient radial lip seals for all applications If a sealing system leaks, it is most important that the manufacturer is provided with as much data about the sealing system and its environment as possible in order to provide a timely and correct solution. A common example of a dynamic seal is a radial lip seal used on a rotating shaft, such as a crankshaft seal in an engine or a shaft seal in a pump

These seals have a flexible rubber lip that stays in contact with the spinning shaft. Good seals for high vacuum systems have both low permeation and low leak Good understanding of chamber rate of rise and diferentiation between leak and permeation are important for high vacuum processing. Why do mechanical seals leak

How to troubleshoot common sealing failures introduction mechanical seals play a critical role in preventing leakage in industrial machinery, ensuring the efficiency and reliability of equipment such as pumps, compressors, and mixers

Shock or other factors cock, can't or misorient the seals in grooves.