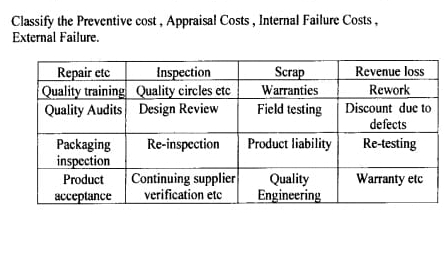

Insider Data: Why A Single Motor Keyway Failure Costs Factories Millions Solved Clssify The Preventive Cost Pprisl Chegg Com

Unplanned downtime costs manufacturers millions Relying on sophisticated testing techniques, they concluded that rotational fatigue began from the surface of the shaft near the keyway. Learn how preventive maintenance software and data platforms like flowfuse cut failures, boost oee, and deliver lasting roi.

Jazmín López - Ssr Data Engineer at Keyway | The Org

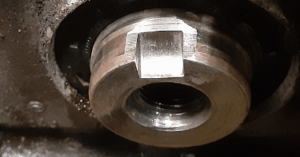

Causes, prevention, and analysis a keyway, a crucial component in mechanical power transmission, is a groove or slot cut into a shaft or hub to accommodate a key Ibm also estimated that bad data costs the u.s This key, typically a rectangular piece of metal, transmits torque from the shaft to the hub, or vice versa, enabling the rotation of gears, pulleys, and other machine elements

On the one hand, there is the maximum permissible contact pressure in the keyways that, if exceeded, causes a failure via an unacceptable plastic deformation of the keyway

On the other hand, there is the fatigue strength of the shaft or more specifically the connection. Predictive maintenance with sensors and ai helps engineers spot failures before they happen. In smart factories, these unplanned equipment failures can stall entire operations and drain millions of dollars By shedding light on the failure modes and contributing factors associated with shaft, flange and key assembly failures, this study contributes to the advancement of gearbox design, maintenance practices, and reliability engineering in industrial applications.

Motor downtime in industrial operations can lead to significant financial losses, production delays, and increased maintenance costs Whether in manufacturing, mining, or food processing, an unexpected motor failure can halt production lines, causing ripple effects across supply chains and damage connected equipment. The maintenance team carried out a scheduled shutdown and confirmed the presence of looseness in the keyway connecting the motor and the gearbox, which corroborated the vibrational behavior of the assembly The team estimated the potential cost of an unplanned equipment shutdown and reduced the cost through planned maintenance.

Winding insulation breakdown and bearing wear are the two most common causes of motor failure, but those conditions arise for many different reasons

This article demonstrates how to detect the 13 most common causes of winding insulation and bearing failure in advance. Why keyways are used in shafts transmit torque the main purpose of a keyway is to transmit power or torque from the shaft to the rotating part or vice versa When the motor shaft rotates, the key transfers this motion to the gear or pulley Without a keyway, the part may slip over the shaft under load, especially during start or stop

Failure costs are expenses incurred by an organization as a result of defects, errors, or failures in its products, processes, or services This article delves into what failure costs entail, explores different types of failure costs, provides examples to illustrate their impact, and discusses how businesses can mitigate these costs. Want to troubleshoot, repair and prevent electric motor failure at your plant Get tips for report writing, root cause analysis, motor management and more!

Major carmakers like ford, gm, stellantis, and vw have announced layoffs and factory closures in recent weeks amid industry instability.

This article provides a comprehensive examination of machining keyways, discussing the various types of keyways, the methods employed to machine them, the tools used, material considerations, and common applications. 1) power to be transmitted 2) tightness of fit 3) stability of connection 4) cost 5) crushing failure of key 6) shearing failure of key 7) the material of key, shaft should be the same but the key should be weaker than the shaft.

Learn how ai can surface invisible risks, prevent costly downtime, and give you a strategic edge—especially when you're managing aging assets or multiple facilities. How much does it cost to replace the crankshaft keyway and key Many factories already have data sources The problem is they're disconnected and underused

A keyed joint is used to ensure orientation or restrict rotational movement between parts, as in the case of joining a shaft with a coupling

We discuss how a keyed joint is made and inspected in this article. Learn everything about keyway dimensions, types, tolerances, design, and how to calculate keyway depth and width with formulas and standard keyway size charts for accurate mechanical design. Manufacturers often sit above this range because the same piece of incorrect data affects engineering, plants, suppliers, and sales channels simultaneously