Inside Data: How Wampfler Tech Is Reducing Crane Downtime By Forty Percent Electro Shear® Brake Reduces Midwest Brake Detroit

Next, leverage all the data from the sensors to form a predictive maintenance plan Simplified maintenance easy access to the crane maintenance locations for minimized maintenance efort and crane downtime. By leveraging operational data, crane operators can detect maintenance issues before they escalate into safety hazards

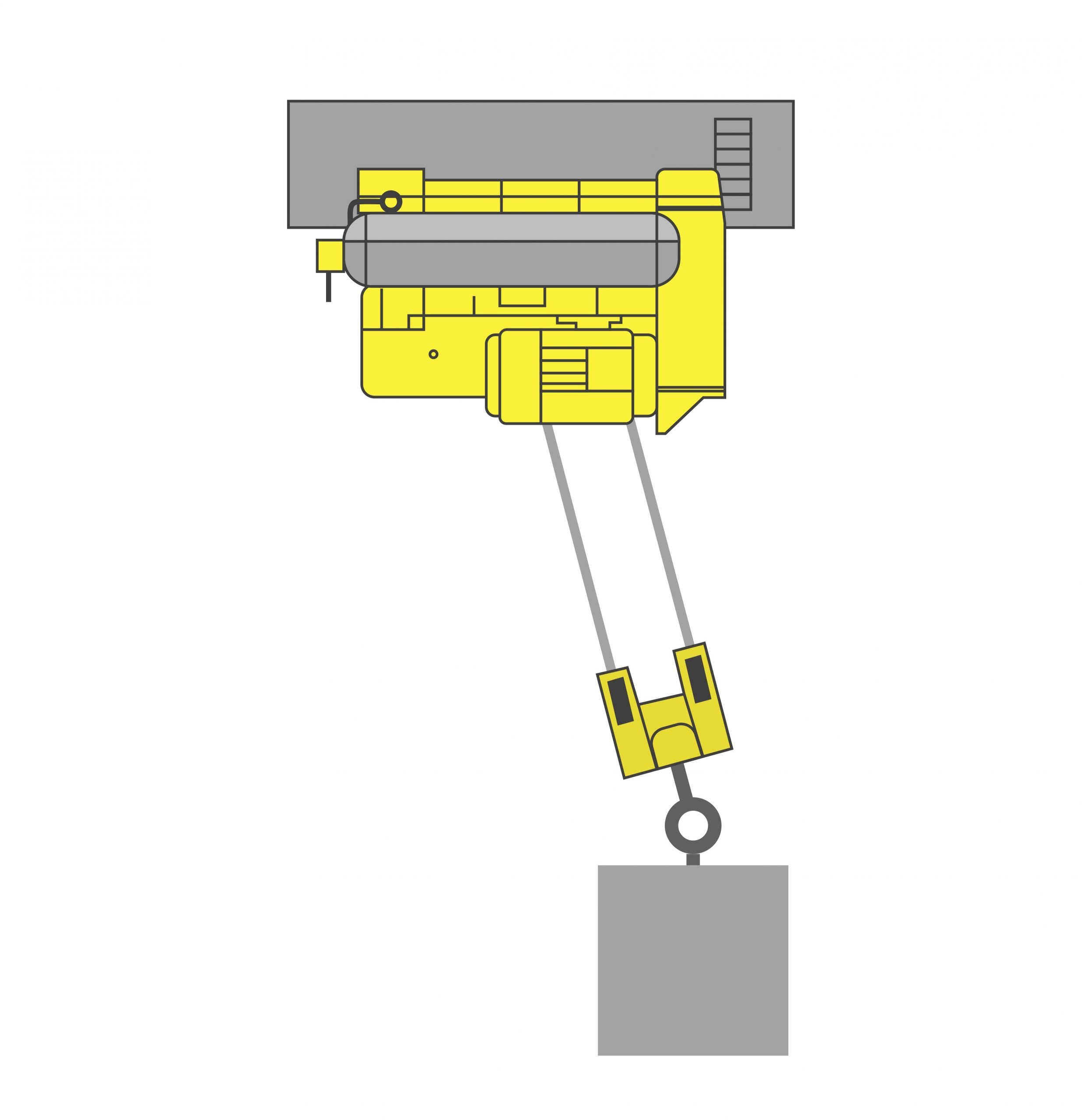

Electro Shear® Brake Reduces Crane Downtime by Midwest Brake - Detroit

Predictive maintenance enables proactive maintenance scheduling, reducing the risk of breakdowns, accidents and downtime. Technical description rubber tyre gantry crane rtg technical data rtg model designation 7/5/4 ws ac drive 4 wheels per corner Mobile cranes play a vital role in the construction industry and require reliable power and data transmission systems that can withstand the toughest conditions

Transform reactive repairs into strategic operations for maximum uptime.

According to oracle and intel, predictive maintenance outranks other maintenance models For starters, it can reduce downtime by identifying equipment and systems that are not running optimally, flagging potential problems early on Second, it increases production by keeping equipment operational. Whether in production, assembly, or logistics, our systems adapt flexibly to the requirements of each crane, ensuring precise motion sequences, maximum productivity, and minimum.

Reducing crane downtime one of the most significant challenges in crane operations is unplanned downtime, which can lead to costly delays and safety risks. Ai enhances crane maintenance by analyzing data from iot sensors to predict when components are likely to fail This allows maintenance teams to perform proactive repairs, reducing downtime and extending the crane's life. In our manufacturing facility, we've focused heavily on predictive maintenance to reduce downtime and improve equipment reliability

This approach uses sensors and advanced analytics to monitor the condition and performance of machinery.

For cranes to operate safely and efficiently, workers must regularly inspect their components to ensure they're fine and don't require any fixes Through proactive crane maintenance, crane users can better identify potential issues before they become major problems, reducing the risk of accidents and equipment failure. Port equipment specialists is frequently called upon by the world's busiest ports for unmatched expertise in preventative and predictive maintenance techniques aimed at reducing downtime and enhancing ports' overall equipment reliability. Our goal is tosuring maximum performance from all of your energy and data transmissions systems.

You can reduce it by 69 percent by switching to the aws cloud, with its highly available network, extensive cloud infrastructure, and global availability zones. Mit hoist, a leading manufacturer of jib crane, overhead crane, electric hoist, light crane system and other important crane components, can help you reduce downsize and improve your business operations. An active preventive maintenance program is crucial to improving safety and productivity Preventive maintenance can reduce downtime and increase reliability

If one of your cranes goes down, how much is it really costing you?

Please switch to a supported browser listed here, or some features may not work correctly. Downtime tracking refers to the collection of and reporting on machine data related to unplanned stops on your production line It is a foundational step for reducing downtime You can only monitor the success of your improvement actions once you have an accurate baseline for comparison.

Get insurance from a company that's been trusted since 1936 See how much you can save with geico on insurance for your car, motorcycle, and more. Navy crane center responsibilities include Procuring designated types of whe in accordance with navcraneceninst 11450.1

Establishing policy regarding design, maintenance, testing, certification, and operation of whe

Establishing training and qualification requirements for whe personnel Evaluating activities who own or operate whe. Grove is the world leader in mobile cranes