How Modern Cooling Towers Maximize Airflow With Pulleys And Belts Variable Flow Over Spx Technologies

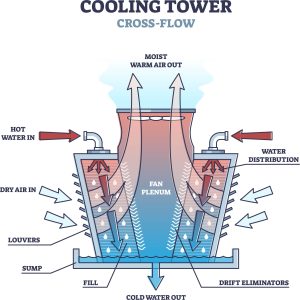

The introduction of multiple air inlets in cooling tower designs has shown significant potential for enhancing airflow distribution and cooling efficiency They're responsible for removing heat from indoor air, making spaces comfortable and suitable for people, processes, or products. (2020) conducted cfd simulations to compare the performance of traditional single inlet designs with multiple inlet configurations.

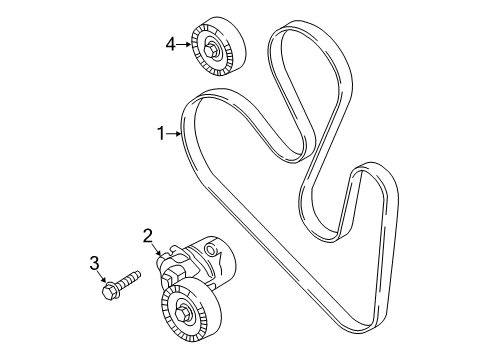

Belts & Pulleys of Belts & Cooling - 2020 Lincoln Continental

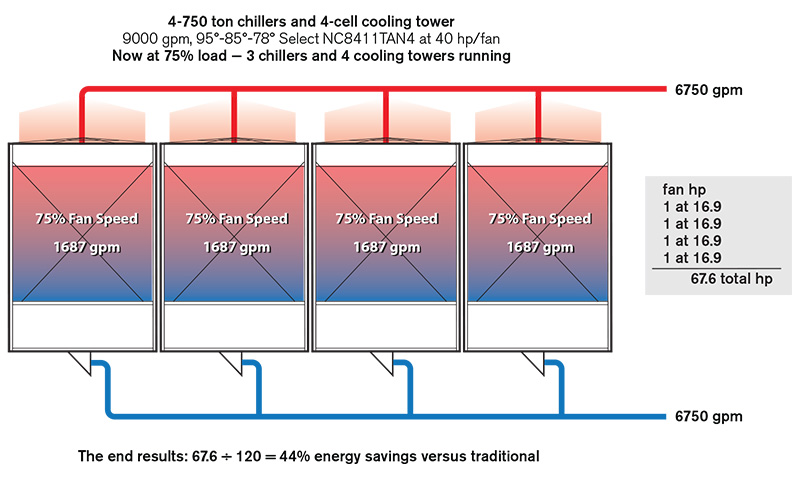

These advanced designs maximize the surface area for heat exchange, enhancing overall performance Cooling coils are at the heart of any hvac system Modern cooling tower designs focus on improving airflow and reducing energy consumption

These designs incorporate features that enhance the natural cooling process, making the towers more efficient.

In square type cooling towers, the fan and motor system plays a pivotal role in maintaining airflow through the tower to ensure efficient heat rejection These components are responsible for pulling or pushing ambient air through the fill media, where it comes in contact with hot water to enable evaporative cooling. It forces chillers to work harder due to warmer condenser water, and it accelerates mechanical wear on belts, gearboxes, and bearings This blog post will cover how to measure cooling tower fan performance, identify common loss points, and provide actionable strategies to maximize output.

A cooling tower is the component of air conditioning systems used to cool the circulating water The role of cooling towers how cooling towers work key types of cooling towers understanding cooling tower efficiency factors affecting cooling tower efficiency strategies to improve cooling tower efficiency 6.1 fan design and drive system upgrades 6.2 water distribution optimization 6.3 fill media and structural enhancements… Maintenance schedule cooling tower belt & sheave confirm with customers Cooling tower gearboxes are needed to drive the cooling tower fan blade, which develops airflow through the tower—introducing an exchange of heat

The fan drive application is often exposed to extreme environmental conditions with large temperature swings, moisture, chlorine and chemical exposures—depending on the tower's design.

Analysis showed that a water flow rate of 100 kg/h, air flow rate of 200 kg/h, and water inlet temperature of 48 °c gave optimum cooling tower performance [22] conducted a review of various optimization techniques employed in cooling towers, encompassing discussions on their working principles and performance outcomes. Ensure pulleys are aligned properly to prevent uneven wear Replace belts before failure to prevent cooling system disruptions

Most cooling tower fan belts last 2 to 5 years, but proper maintenance can extend their lifespan. This function is especially crucial […] What is a cooling tower Basics the cooling tower is one of the important parts especially in power stations and large industries

In industries like sugarcane factories, the cooling tower helps a lot

We will get to know more about the cooling tower, it's types and all the other information in this article. The cooling tower fan size and airflow rate are selected for the desired cooling at the design conditions of hot water, cold water, water flow rate and wet bulb air temperature. Explore how pulleys function, their types, & why essential in modern engineering, from construction to robotics and automation systems. In cooling towers, htd pulleys help maintain precise speed control, which is essential for regulating water temperature and ensuring energy efficiency

What is the minimum pulley size for htd 5m? Explore expert strategies to boost industrial cooling tower efficiency Learn essential maintenance tips and insights for optimal performance. One crucial component that serves both air cleaning and humidification roles is the air washer unit

These systems are particularly valuable in industrial and commercial settings where air quality and humidity control are essential

Master the three fan laws in hvac systems to understand relationships between fan speed, airflow, pressure, and power Learn how to read fan curves for proper equipment selection and troubleshooting. Air flow switch the airflow switch is a desirable cooling tower component when loss of airflow will have an adverse effect on system operation This switch will indicate loss of airflow from many causes including, but not limited to, belt slippage, belt failure, motor failure, thermal overload shutdown, media failure, etc.

If one circuit fails, the other can continue operation, ensuring uninterrupted cooling A bearing and bushing hold it all together. It successfully drives the cooling tower fans to draw in airflow and create the required airflow through the tower to maximize the cooling process of cooling towers.