How Future Jet Engines Will Utilize A Redesigned Bearing Retainer Ring 13194 Be Retiner Mercury Mrine Crowley Mrine

Rolling element bearings are the most critical parts of any rotary mechanism This is not a snap ring that can be easily removed with snap. One of the challenges in any bearing design is to minimize the friction and maximize life for a particular service environment

Bearing Retainer Ring - PBM-1000 / 2000 / 2500 / SUPER - Gate Machinery

For critical aerospace systems such as jet/liquid rocket engines, bearings are the key to improving performance benchmarks Andy phillips shows how to quickly remove a bearing retainer ring, with no special tools needed Though bearings are a common machine element, literature related.

In jet engines, bearings can operate at over 200 c (400 f) and speeds over 10,000 rpm for the turbine shafts and over 30,000 rpm in the accessory drives

Auxiliary power units (apu) operate at around 60,000 rpm. Discover the latest technologies transforming jet engines From adaptive cycle engines and electric propulsion to 3d printing and supersonic flight, explore how these advancements shape the future of aviation. As global air travel continues to grow and environmental sustainability becomes paramount, jet engines—the beating heart of modern.

Jet engine technology plays a crucial role in modern aviation, offering improved fuel efficiency and performance This paper explores the design, evolution, and future potential of ramjet engines, with a focus on their role in advanced propulsion systems It starts with a historical overview of jet engine. Turboprops—jet engines with propellers—are popular for smaller airplanes and large cargo aircraft, but a new generation of open rotor fan engines that combine some of the benefits of high bypass ratio turbofans and turboprops promise to revolutionize large aircraft design.

This article will begin with an introduction to the different types of jet engines and then detail the design, benefits, and issues of the cfm international cfm56/leap engine

Finally, there is some description of the future of jet engines, including materials, greater efficiency, and applications in space exploration. For efficient operation of aircraft engine, high quality bearings are necessary Learn more about the aircraft engine bearings and different types of jet engine bearings. Threaded retainer retention threaded bearing retainers offer an excellent bearing retention method due to ease of bearing replacement, high axial thrust load capabilities, and ease of assembly in areas where accessibility to conventional staking would be difficult

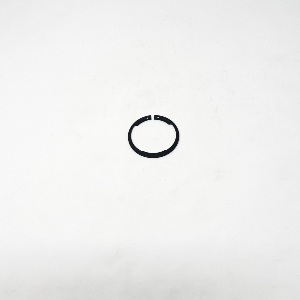

A ball bearing assembly consists of grooved inner and outer races, one or more sets of balls, in bearings designed for disassembly, and a bearing retainer They are used for shaft bearings and rocker arm bearings in some reciprocating engines. Explore key insights on bearing retainers, their types, materials, and benefits for optimal bearing performance and durability. Jet engine shaft bearings and accessory drive shaft bearings typically use single piece or two piece machined retainers

Temperature and moisture resistant oils, greases and lubricants are normally specified.

There is a flange on the retainer body that attaches to the lower centering ring instead of bonding to the motor mount tube Stainless steel socket head screws and threaded inserts are included. Constantly working to extend their time between overall (tbo), engine manufacturers and operators use modern materials in seal designs. Modern jet engines require bearing retainers that can provide reliable service under stringent and unusual conditions

In current commercial transports, these engines commonly operate at 1.5 × 10 6 dn for 12000 hours or more between overhauls, and in military applications, the cage and bearings are required to retain its integrity when the oil. This datasheet provides information on composition, physical properties, hardness, and elasticity It also includes information on forming, heat treating, machining, joining, and surface treatment. Abstract rolling element bearings are the most critical parts of any rotary mechanism

For critical aerospace systems such as jet/liquid rocket engines, bearings are the key to improving performance benchmarks.

A full complement (or full ball) bearing contains extra balls and has no retainer It is used for its greater radial load capacity although axial load capacity is very small These bearings can only be used at low speeds and bearing torque is increased due to ball to ball friction Improved steel and hardening techniques have increased the load capacities of bearings with cages and the full.

The purpose of this book and the companion course is to present to engineers the knowledge that has been gained about jet engines and propulsion systems over the past half century A number of people have worked together for well over a year to bring about the publication of this book.