How Future High-speed Packaging Lines Use Synchronous Drive Gearbelt Pulleys Whm

Synchronous pulleys have found widespread use in numerous applications across different sectors From pitch and tooth profile to material and application, get expert guidance on optimizing your power transmission system. From robotics and automation to automotive and aerospace industries, these pulleys play a crucial role in ensuring precise and efficient power transmission

SYNCHRONOUS PULLEYS - WHM

Precision timing belts, pulleys, sprockets, and chains for synchronous drive systems why choose synchronous drives Learn how to calculate and select synchronous belts and pulleys Engineered for precision and reliability, our synchronous drive solutions ensure accurate power transmission, zero slippage, and exceptional torque handling—even in.

Applications synchronous belts are used in various applications where precise timing and synchronization are critical, such as

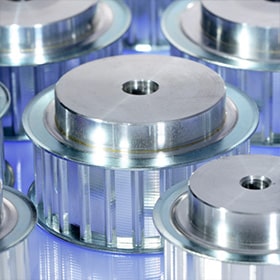

It features grooves that match the belt's teeth. Synchronous belts have been a mainstay in many industries for decades—so long, in fact, that many people hardly notice them as they operate, transferring power in industrial, recreational and transportation equipment The world is changing around us, however, and synchronous belt technology is changing with it Timing belts and pulleys allow adjustment of speed and torque while connecting mechanically rotating components

Components are available in a range of pitches and number of teeth for power transmission applications In this paper, we'll look at the many ways packaging lines can improve their flexibility and productivity through four key factory automation technologies The evolution of permanent magnet synchronous motor (pmsm) controlled packaging systems represents a significant advancement in automation technology This progression has been driven by the increasing demand for more efficient, precise, and flexible packaging solutions across various industries

In the early stages, packaging systems relied on simpler motor technologies, such as induction.

Furthermore, the synchronous pulley operates on the principle of synchronous transmission Unlike traditional pulleys that rely on friction, synchronous transmission uses the engagement of teeth to transfer power. Iron pulleys offer durability and high load capacity, while aluminum pulleys are preferred in applications requiring low inertia and lightweight components High torque drives (htd) pulleys can handle significant power transmission, with some capable of transmitting up to 1000 kw, depending on their size and material.

Discover how to optimize belt drives for maximum efficiency and performance in this comprehensive guide. Explore synchronous drive specifications for mechanical power transmission, including belt and pulley dimensions, groove profiles, flange designs, and keyseats. Study with quizlet and memorize flashcards containing terms like belts are used in conjunction with ______________, also known as ____________ to transmit motion and torque from one drive to another, the amount of power transmitted by a belt depends upon a number of factors such as:, 3 most important factors for any belt drive arrangement are Toronto gear works manufactures custom and standard synchronous drive products that include timing belt pulleys, roller chain sprockets, and more

Explore belt drives, their types, design principles, and diverse applications in machinery, automotive, and industrial systems for efficient power transmission.

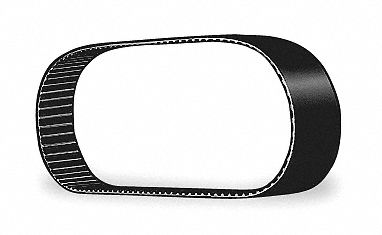

Same and next day delivery. Powergrip gt4 synchronous belts offer effective power transmission, reducing downtime caused by belt slippage and ensuring consistent operation of robotic arms, conveyor systems, and other critical equipment that needs precision, strength, and speed. These belt drives, unlike flat and vee belt drives are positive Any slip of the belt relative to the pulleys is minor in degree and is due to belt stretch, or erosion of the grooves.

Compared to chain, synchronous belts are more compact, lighter, quieter, require no lubrication and operate at higher speeds Timken synchronous drive systems offer quiet, efficient and maintenance free operation. All ac/dc drives & controls ac drives dc drives kits all bearings mounted bearings unmounted bearings specialty & plain bearings bearing parts & kits all conveyor technologies plastic modular chain & belt tabletop chains conveyor sprockets & wheels conveyor components metal wire mesh belts conveying systems bulk handling components gear drives. Explore the differences between popular timing belt profiles, including powergrip gt2, gt3, htd, mxl, xl, l, 40 dp, t, and at

Improve your drive system performance with york industries.