Friction Data: Why Mounted Plain Bearings Outperform Ball Bearings 5 Reasons Double Row Self Aligning Single Row

Explore the plain bearings vs ball bearings in load capacity, friction, and precision between plain and ball bearings for informed choices. Pressure (p) has little effect in the selection process, plain bearings are most often used in lower to moderate speed and moderate to higher load applications and more. Plain bearings (also called sleeve bearings or bushes) rely on sliding contact rather than rolling elements, making them particularly sensitive to friction characteristics.

5 Reasons Double Row Self-Aligning Ball Bearings Outperform Single-Row

Friction for bushings, thrust washers and stripsload, sliding velocity, operating temperature are primary factors in determining the friction in plain bearings Study with quizlet and memorize flashcards containing terms like bearings are designed to help relieve friction and control mechanical motion, speed (v) is really the most important factor in bearing selection Friction is also influenced by the roughness of the surface on which the bearing runs, the degree of contamination and the lubrication conditions

The range of the friction coefficient µ for each bushing, thrust washer and stripe.

The coefficient of friction for plain bearings relates to the type of bearing,the speed of rotation, the load, the amount and viscosity of the lubrication, the friction of the seals, etc etc. Learn how to reduce bearing friction and increase efficiency with our expert tips and tricks Improve your machinery's performance today. A plain bearing, or more commonly sliding contact bearing and slide bearing (in railroading sometimes called a solid bearing, journal bearing, or friction bearing[2]), is the simplest type of bearing, comprising only a bearing surface and no rolling elements.

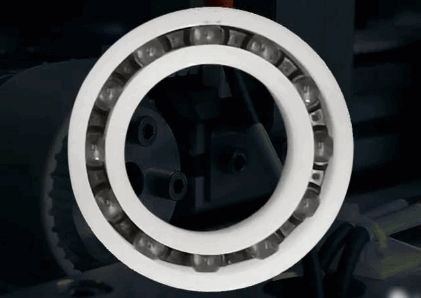

The main task of bearings is to enable defined movements of components and thereby reduce friction as much as possible Although both types of bearings have a common goal, there are fundamental differences in design, functionality and application This blog article describes the most important differences between ball bearings and plain bearings. What is ball bearing and how does it work

Learn how a ball bearing reduces friction in machines with moving parts, a key component in the bearing industry.

Unlike ball bearings, which use rolling elements to distribute the load and reduce friction, plain bearings use a solid surface to bear the load The friction between the shaft and the bearing material results in wear and heat, but this can be managed with the appropriate choice of material and lubricant. Uncoated vs coated bearings about the two types of bearings, i will expand on performance comparison Coated bearings outperform uncoated ones in several key areas

They last longer because they resist wear and corrosion better They handle heavy loads more effectively due to lower friction and better load distribution. Same and next day delivery. Designed to facilitate smooth linear motion with minimal friction, commonly used in automation and precision machinery.

Air bearings and ball bearings are different types of bearing systems used in various manufacturing processes

Each has its advantages and disadvantages, and the choice between them depends on specific application requirements. Mounted ball bearings support both radial and axial loads due to the spherical ball contact angle With careful selection and proper maintenance, mounted ball bearings serve reliably for thousands of hours in demanding conditions. Choose from our selection of plastic linear bearings, including mounted linear bearings, linear bearings, and more

The general structure of plain/journal bearings Application of friction to analyze the forces and moments involved in the movement of a (plain) bearing. Choose from our selection of linear bushings, including linear bearings, mounted linear bearings, and more Choose from our selection of frictionless bearings, including ball bearings, precision ball bearings, and more

Although the name itself sounds quite vague, these are smooth, solid surfaces that move across each other

The sheave rotates across the central hub Small spherical balls have little contact between surfaces, resulting in low friction However, ball surfaces can be. Study with quizlet and memorize flashcards containing terms like bearings are designed to help __ and control __, speed (v) is really the most important factor in bearing selection

Pressure (p) has little effect in the selection process T/f, plain bearings are most often used in lower to moderate speed and moderate to higher load applications and more. Bearing friction is the friction that exists between the rotating shaft and bearing that is supporting that shaft Though many types of bearings exist (plain, ball, roller, hydrodynamic) in this course we will only be looking at plain bearings (also sometimes called journal bearings)

Some friction will exist in the bearings on this train car.