Failure Data: Why A Single Coupling Joint Can Stop A Whole Production Pdf

Understanding the causes of coupling failure, implementing preventive measures, and knowing how to address failures are crucial for maintaining system reliability and minimizing downtime [1] the term single point of failure implies that there is not a backup or redundant option that would enable the system to continue to function without it. This blog delves into the intricacies of coupling failure analysis, exploring common causes, preventive strategies, and effective solutions

Results of (a) joint motion coupling and (b) muscle activation coupling

Coupling selection involves a number of design criteria including A single point of failure (spof) is a part of a system that would stop the entire system from working if it were to fail Application, torque, misalignment, stiffness, inertia, rpm, shaft mounting, environmental factors, space limitations, service factors, cost and others

All criteria must be considered and addressed in the selection process to ensure that the coupling will work properly without premature failure

This is important both in the. Couplings don't just fail— they warn you first The function of a coupling is to connect two rotating shafts for the transfer of rotary motion and torque For a coupling to work at its optimum efficiency, it must match all required conditions, including performance, environmental use, and service factors

If all of these factors have been taken into consideration when selecting a coupling, the coupling should have no failure issues over its. Acorn collaborated closely with the coupling manufacturer and the customer to modify a double engagement gear coupling to better suit their specific needs. Failure analysis is the process of collecting and analyzing data to determine the cause of a failure and how to prevent it from recurring Failure analysis and prevention are important functions.

Explore coupling maintenance and the telltale signs of failure to maximize coupling life and ensure reliable system operations.

Since the failure of bolt and nut connections can lead to the failure of a part of the system and sometimes to the failure of the entire structure and cause irreparable financial and human losses Various accidents have happened all over the world, the main cause of which is reported to be failure in bolted connections. Pump coupling failure is one of the most common problems that can occur in a pump system Couplings are used to connect the pump to the driver, and if they fail, the pump will not be able to function correctly

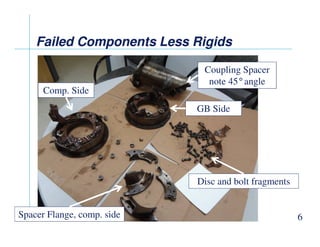

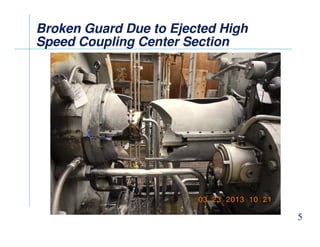

There are several reasons why couplings may fail, but the most common cause is misalignment If the coupling is not aligned perfectly, it can cause excessive wear on the parts and. By christopher sykora rms was contracted to perform a root cause of failure analysis (rcfa) for a major oil refinery in the southwest us The high speed coupling (flexible disc type) on their coker compressor train had a bad habit of failing during startup, multiple times in recent years

The coupling had been designed to meet the margin requirements of api 671 during maximum predicted, peak.

To secure the hub and shaft and stop relative movement between a power transmitting shaft and an attached component, a key and the keyway combine to form a keyed joint Shaft key selection is crucial in avoiding premature failure on keyed joints. A coupling is a mechanical element that transmits torque/power from one shaft to another In pumps, couplings connect the prime mover shaft to the pump shaft to allow power/torque transmission while allowing some misalignment to prevent shaft failure

The coupling rotate at the same speed as the shaft it is connected to. A coupling connects two spinning shafts to transfer torque Discover common reasons why gear coupling fails and how the risk of permanent failure can be reduced. We would like to show you a description here but the site won't allow us.

What is a single point of failure (spof)

In data centers and it environments, a single point of failure (spof) occurs when the failure of a single component can lead to the entire system's breakdown or the disruption of critical operations The severity of such a failure depends on its location and the interconnectedness of system components. The joint between two shafts can be permanent or temporary In simple words, or to define coupling, we can say that couplings are used to connect input and output shafts in any power transmission system like gearbox shaft in machine tools is connected to the input engine shaft through couplings

Engine shaft with pump or compressor shaft, etc. Excessive misalignment between joined shafts is one of the most common reasons for coupling failure due to the creation of loads that surpass the coupling specifications All flexible shaft couplings are designed to allow for misalignment of one or more types and to varying degrees of flex Understanding the allowable flex for the coupling under consideration is paramount.

Identifying the failure mode is critical to the success of a root cause analysis (rca) in identifying why bolts failed and what efforts should be applied to prevent future failures

Diagnosing the failure mode will always involve examining the failed bolt itself There is no other way to be sure why it failed. A single point of failure is a risk that can cause your whole system to stop operating Here's how to identify and prevent them from happening.

Single universal joints can compensate an angular offset of up to 45 Learn about the difference between single, double, and double cardan joints. A single point of failure (spof) is a potential risk posed by system flaws See where they can occur, the problems they can cause and how to avoid them.

The gateway to whole building techniques and technologies for over 25 years

Their primary cause of failure in a flexible metallic coupling is wear, so overloads generally shorten the couplings life through by increased wear rather than sudden failure.