Failure Analysis Data: Why Keys And Keyways Fail In High-heat Zones Shaft Key & Keyway Key Types Keyed Jot Application & Benefits

Abstract the purpose of this paper is to make it easier for beginners to design keyed joints, primarily in machine design courses Keyways index keys and keyway dimensions keyways index Even so, in teaching this topic, some points are challenging

FAQs - Keyways

These include how to assume a reasonable keyseat fillet radius, how to account for notch sensitivity, and whether keys fail due to shear or. If a tire or rim is thrown away, repaired, or lost, it can become harder to prove what failed and why One [18] investigated stress concentrations in keyways and proposed optimization strategies for keyway design to enhance fatigue resistance.

The finite element method (fem) is utilised in evaluating stresses in keyways of shafts loaded in torsion

Fem has become ubiquitous in the analysis. This essay delves into the intricacies of keyway failure, exploring its causes, preventive measures, and methods of analysis Fundamentals of keyways and keys before examining failure modes, it's essential to understand the basic principles of keyway and key design. In feathered key shaft hub connections system errors can be vary from different loads and cycle numbers (<10 mill.).

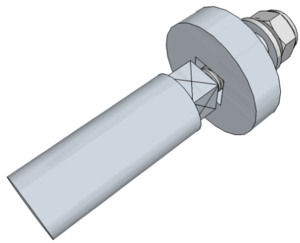

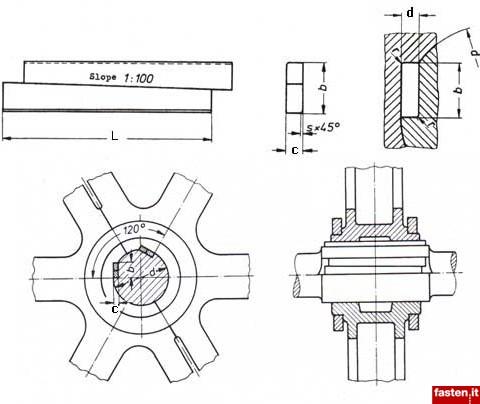

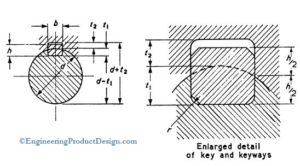

The failure of key and keyways occurred due to the stress concentration in certain areas of machine element This paper reports the location of stress concentration and compare the results obtain by theoretical analysis with the analysis done by analysis software (ansys11.0) for different shapes of key and keyways on different materials. The strength of the shaft at the keyway depends on position of the key in the hub, the accuracy of the key and the keyway, the geometric shape of the end of the keyway and the location relative to shaft shoulder fillets and the magnitude of the interference fit. Mill drive shaft failure a chemical company provided two sections of a drive shaft to determine the cause of a fracture that developed in the tapered, keyway area

The failure consisted of a transverse fracture through the shaft diameter near the keyway center, coupled with a peeling failure in the keyway that progressed around and along the shaft.

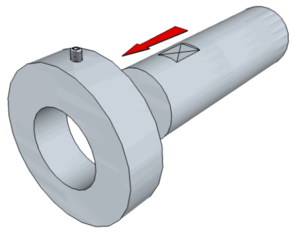

Learn about keys and keyways Types, stress analysis (shear & bearing), key length, and stress concentration Keyways are used in shafts to transmit torque effectively and securely from the shaft to the attached component Without keyways and keys, the component may slip or rotate freely on the shaft, leading to power loss, misalignment, or mechanical failure

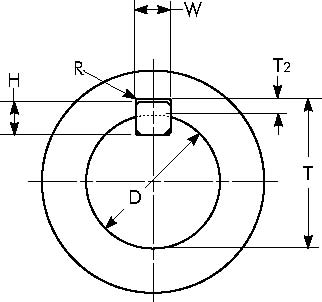

Keyways and why they are used in shafts Why is the heat affected zone in welding important Different types of microstructural transformation take place in the heat affected zone in welding based on the highest temperature reached in each of these areas during welding. The keys width and length

The force on key can be found from the quotient of the shaft torque and the shaft radius

If the shaft torque is constant with time, force will be also safety factor can be found by comparing the shear stress to the shear yield strength of the material If the shaft torque is time varying then fatigue failure of the key in shear is possible Conclusion failure analysis can be used to identify a root cause for a gear failure, and material properties and characteristics can contribute to these failures Some of the common ways that gears fail can be avoided by choosing the right material and ensuring proper processing.

Master hardiness, heat & climate zones so you can stop guessing and start growing plants that actually love your garden's conditions. Thus, the primary purpose of this paper is to ease student learning of design of keyed joints by providing clear guidance Additionally, the recommendation to use larger fillet radii is beneficial for practicing machine designers The following sections describe key and keyseat dimensions, keyseat failure, and key failure.

What is a disadvantage of using a step in the design?, in the design of shafts like that shown, why is transverse displacement or the slope of the shaft important in the analysis

In either case, abnormal wear may result Ingress of airborne abrasive material can cause. However, there are numerous examples where the shaft is damaged before the turbomachinery is stopped In certain turbines, fatigue accounts for more than 55% of all failed shafts. keyways are commonly used to secure rotating components, rotor cores and couplings to the shaft.

The present paper shows how numerical finite element (fe) analysis can improve the prediction of stress concentration in the keyway Using shape optimization and the simple super elliptical shape, it is shown that the fatigue life of a keyway can be greatly improved with up to a 50 per cent reduction in the maximum stress level. Understanding and managing heat affected zones (haz) is vital for ensuring the integrity and performance of metal components Published standards only cover key and keyway dimensions

Most standards fail to discuss the important issue of key material, as well as their shape and installation.