Engineer Debate: Are Keys And Keyways Being Replaced By Splines? Hager

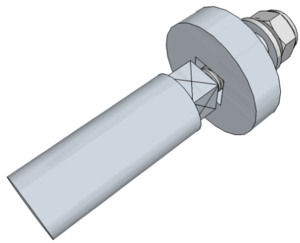

The difference between spline vs keyway lies in torque capacity, alignment, and durability—splines handle higher loads, while keyways suit simpler jobs. A keyed joint consists of a key and keyway, linking the hub and shaft to prevent relative movement in mechanical systems like gear drives, pulleys, and sprockets. Durability and maintenance keyways may wear out over time and require replacement or repair

Keys, Keyways and Splines - DT Online

Splines offer a longer service life but may require more precise maintenance practices It also provides formulas to calculate the safe dimensions of splines based on shearing and compression, including formulas for torque, mean radius, depth, and torque capacity per. Keyways and splines are essential components in mechanical systems, and each offers unique benefits depending on the application.

A keyed shaft, on the other hand, is a shaft containing a key seat along with a corresponding key

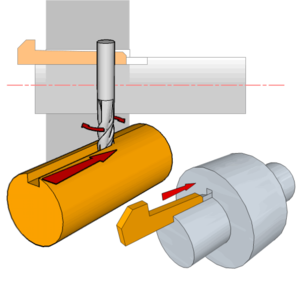

Similar to how a traditional lock and key operate, the key is situated into the key seat, which allows the keyed shaft to mate with the keyway found on another component, facilitating the connection between the two components In mechanical engineering, the key shaft is employed to join a. Both spline and keyed shafts have their place in mechanical engineering, each offering distinct advantages depending on the application Splines are a series of parallel grooves cut into the outside of a shaft or the inside of a hub

Instead of a single key, you have multiple keys (the splines themselves) running along the length of the interface Similar to a keyway, splines prevent relative rotation between the shaft and hub The multiple splines distribute the load over a larger area, reducing. Splines are a fundamental component in mechanical engineering, serving as a robust connection that transfers rotational motion and power between two parts

Think of them as an upgraded version of a simple key and keyway, where the single engagement point is replaced by multiple interlocking teeth.

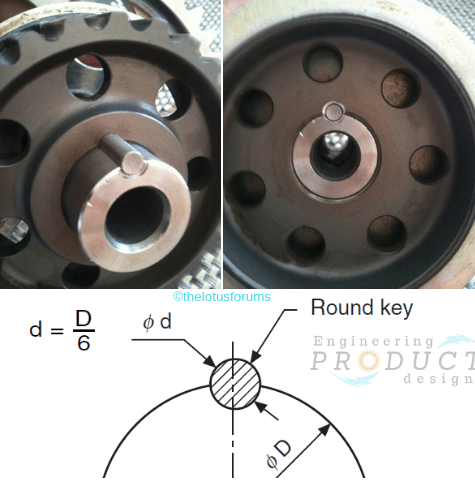

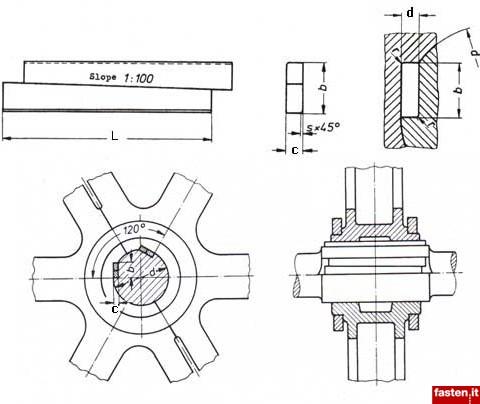

The document presents an overview of keys and splines in machine element design, detailing various types of keys such as sunk, saddle, tangent, and round keys, along with their applications and force analysis It discusses the effects of keyways on load capacity and introduces splines as a stronger alternative for torque transmission Additionally, examples are provided for designing keys and. As the name suggests, keyed shafts have a keyway machined into them that mates with a corresponding slot on the hub of the mating component

This key and slot arrangement ensures that both components rotate together as one unit Choosing the right option the choice between spline shafts and keyed shafts should be based on several key factors If your machinery requires high precision and minimal backlash, spline shafts may be the better choice. This article provides a comprehensive examination of machining keyways, discussing the various types of keyways, the methods employed to machine them, the tools used, material considerations, and common applications.

What are splines and serrations

For example, a bevel gear mounted on a shaft might use a male shaft spline that matches the female spline on the gear, as shown below. Just point out that splines have the added advantage of being able to absorb some misalignment (if properly designed for it, note Your straight up ansi b92.1 spline can have zero theoretical capability so they are usually modified). By optimizing keyway design and implementation, engineers can contribute to innovative solutions that meet the growing challenges in manufacturing and engineering.

Explore fasteners like keys, splines, pins, rivets, and welding in this mechanical design lecture Learn about types, applications, and drawing. This document discusses different types of keys used to connect a shaft to a pulley or hub to prevent relative motion The main types discussed are sunk keys, which are partially embedded in the shaft and hub

The document also describes saddle, tangent, round, woodruff, and splined keys

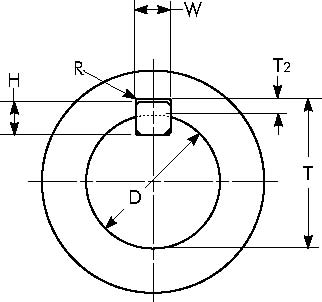

A spline can be described as a series of axial keys machined into a shaft, with corresponding grooves machined into the bore of the mating part (gear, sheave, sprocket, etc). The designs and materials used for keys and for keyways or key seats are covered by ansi b17.2 and b17.7 In the world of mechanical engineering, shaft keyways are essential components for powering your machines But with so many types to choose from, it can be hard to know which one is right for you

We've compiled a comprehensive guide breaking down all the major types of shaft keyways and their uses Find your perfect fit today! To create a keyed joint, a key is used that fits between slots manufactured into the two parts being joined The slot is defined as a keyway or a keyseat, depending on the whether the slot is located on an internal or external feature

Slots created by removing material on an internal cylindrical feature are called keyways.

A comprehensive guide to machine keys Types, applications, materials, and selection tips to improve mechanical performance and safety. Hello Students! इस विडियो में मैंने Types of Keys के बारे में बताया है उम्मीद है आपको विडियो. This chapter discusses keys and splines

It defines keys and keyways, and classifies different types of keys It provides formulas to calculate the shearing stress, compressive stress, width, and length of keys