Damping Data: Why The Elastic Coupling Is Essential For Pumping Ops Model Manufacturer

Elastic couplings offer numerous benefits, including vibration damping, misalignment accommodation, and shock absorption We're on a journey to advance and democratize artificial intelligence through open source and open science. These benefits result in quieter, more reliable pump operation, reduced maintenance costs, and longer equipment lifespan.

Elastic Coupling/Elastic Coupling Model/Elastic Coupling manufacturer

Stiffness (also referred to as spring stiffness) and damping are two essential physical quantities in this context It has been proved by many power installations at home and abroad. Stiffness is defined as the ability of a body to resist elastic deformation

Depending on the direction of load, the differentiation is made between tensile/compressive/bending and torsional/spring stiffness.

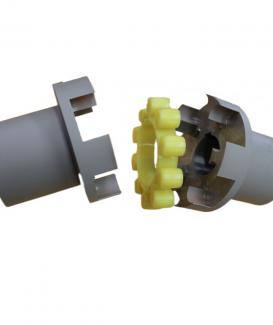

Vibration damping precision couplings in light of the advantages of elasticity, strength, resilience, and damping effects, elastomer materials are now being used in most areas of mechanical engineering In drive technology, beyond transmitting rotary motion and compensating for misalignment between shafts, elastomer couplings (fig 1) are used to damp rotational movement, especially in areas. Discover the diverse world of pump couplings—vital components that ensure the efficient and reliable operation of machinery by connecting motors to pumps

Explore the characteristics and applications of various types, including flexible, grid, gear, disc, elastomeric, universal, fluid, and magnetic couplings Uncover how each type caters to different operational demands, alignment needs, and. Elastomeric coupling for pumps introduction to elastomeric couplings elastomeric couplings are integral components used in pump systems They provide a flexible connection between two rotating shafts, accommodating misalignment and dampening vibrations

Types of elastomeric couplings the primary types include jaw, tire, and sleeve couplings, each offering unique benefits depending on the.

An important technique useful to make easier optimization in the case of nonlinearities is related to the stochastic linearization Elastic couplings are essential components in mechanical power transmission systems They serve a critical function To connect two shafts while accommodating misalignment, absorbing shock, and mitigating vibration

This essay explores the diverse world of elastic couplings, delving into their various types, operating principles, advantages, and applications Elastic couplings from abs are designed to provide flexible and reliable power transmission while effectively damping vibrations and compensating for misalignments These couplings are ideal for applications where shock absorption and the ability to handle angular, axial, and radial misalignments are essential. The expressions for both high damping and low damping are included and evaluated

This study is considered as the first comprehensive review article presenting the theoretical derivations of a large number of damping parameters and the relationships among many damping parameters, with a quantitative evaluation of accurate and approximate formulas.

Benefits of using elastic couplings in pumps elastic couplings offer numerous benefits, including vibration damping, misalignment accommodation, and shock absorption What are damping and damped oscillations What are the types of damping Check out the damping equation

Learn the damping coefficient (constant). Elastic coupling for pumps introduction to elastic coupling elastic couplings play a crucial role in the efficient functioning of pumps They are designed to transmit torque while accommodating slight misalignments and damping vibrations, thereby protecting the pump and extending its lifespan How elastic couplings work elastic couplings consist of flexible elements that absorb torsional.

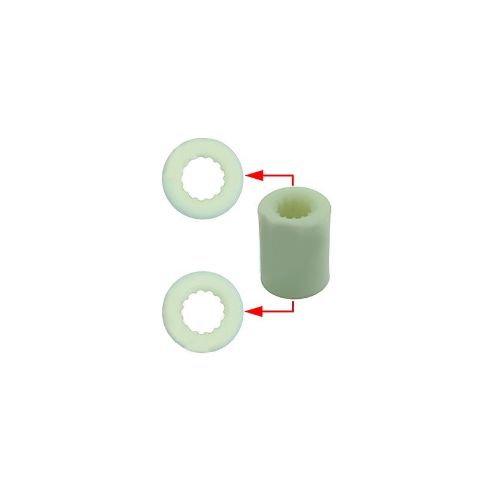

Sometimes bigger is better a customer sizing an elastomer insert coupling recently asked us if using a larger body size would provide better vibration damping

In a word, the answer was, yes Vibrations in machine shafts come from a wide variety of sources. Of course, all real world systems have some level of inherent damping, but this demonstrates the important role that damping can play in vibration isolation When a vibration isolation mount with very little damping is used at or near resonance, the energy amplification can create many problems, ranging from a simple increase in noise levels to.

Pump motor couplings are essential components in mechanical systems, connecting the pump and motor shafts to transmit power efficiently Understanding the various types of couplings ensures optimal performance and longevity of machinery. Highly flexible shaft couplings compensating for high displacements and damping vibrations highly flexible shaft couplings are suitable for offsetting high axial, radial and angular displacements and damping vibrations and torque shocks. Essential information for torsional vibration calculations reliability of torsional vibration calculations depends on the completeness and accuracy of the input data

The information below should be available to make a proper calculation.

At r+w we have machined flywheel features directly into steel coupling hubs on many occasions in order to assist customers with torsional vibration damping, especially in pump coupling applications. High damping performance rubber coupling for servo motors and stepping motors The newly developed rubber element achieves high damping and low reaction force It absorbs vibrations more quickly than flexible couplings that use metal for their elastic parts

This suppresses the resonance phenomenon that can occur in stepping motors, etc.