Critical Tolerance Data: Why Your 5/8 Drill Tap Size Needs Precision And Chart Metric Sherygplus

Machinist drilled hole tolerance capabilities chart per Roll tapping is a process which forms a thread in the hole by. Quality and position of tolerance determine the tolerance zone, which is identified by the appropriate figures and letters

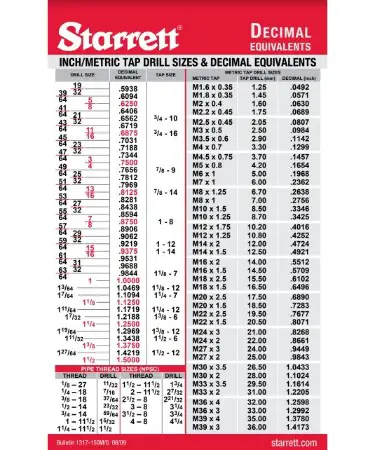

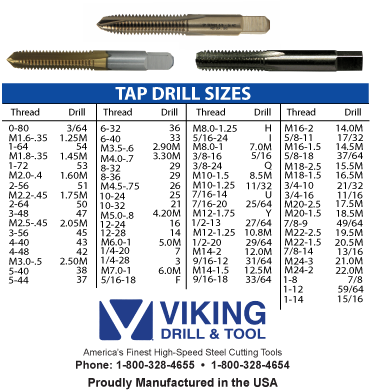

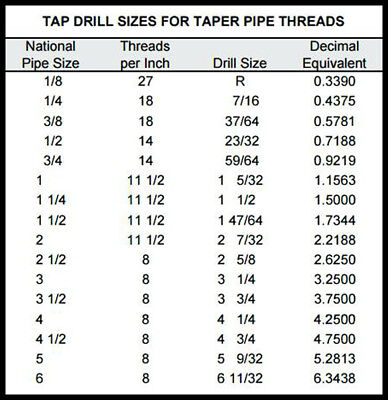

Drill Tap Size Conversion Chart: Decimal, Metric, Number, Letter

The abbreviation for the tolerance class of tap corresponds to the tolerance zone of the internal thread for which the tap is used in most cases. Desired thread size and % of full thread are input parameters for the calculator When it comes to determining the correct drill size for a 5/8 tap, it's essential to understand the relationship between drill sizes and tap sizes

A tap is a tool used to create threads in a material, and the size of the tap is critical in achieving the desired thread size and pitch.

Tap drill size calculator for inch and metric threads (for cutting and forming taps) Plus formulas and charts for tap drill size. Discover the crucial relationship between tap and drill sizes, specifically focusing on the ideal drill size for a 5/8 tap in precision projects Learn how to calculate the correct size, choose the right bit, drill accurately, and avoid common mistakes for flawless threading and successful tapping results.

These modern marvels produce holes closer to the measured size or smaller While this enhances precision, it places a higher workload on the tap A shift to a 13/64, no 6, or even a no

5 drill might be necessary to maintain the desired thread height.

The recommended practice for roll taps is to drill and ream the hole The thread dimensions are formed by a combination of the tap and tap drill size This recommendation chart is a starting point The tap hole size may need to be adjusted based on your specific tolerance, material, and hardness

Converting between inch and metric will help finding drills of similar size. Welcome to our tapping sizes and clearance holes chart, essential for everyone in the field of precision engineering needing to tap holes for metric and imperial threads or provide a through hole for a fastener This handy tap drill size chart is designed to provide you with detailed, practical information to ensure the accuracy and effectiveness of your threaded assemblies Use our tap drill charts to find the right drill size for screws or bolts and ensure perfect threading every time.

Comprehensive tap size chart for manufacturing and machining

Includes fractional, metric, and numbered screw sizes, decimal equivalents, pitch, and recommended tap drill sizes for threading operations. Discover the ideal drill bit size for a 5/8 tap with expert guidance in this comprehensive article Gain insight into tapping basics, material selection, and essential steps for successful thread creation Uncover invaluable tips to enhance your tapping skills, avoid common mistakes, and achieve impeccable results in your diy projects.

This post will show how to utilize a thread tap size chart to get the right dimensions for your application Understanding how to determine the right tap size for machining, vehicle repair, or other technical operations promotes a good fit and material lifetime. Unit conversion calculator to convert the following units acceleration, area, torque, electrical, energy, force, force / length, length, light, mass, mass flow. Screw/thread size, major and minor diameter, drill size, decimal equivalent

Tapped hole, close fit, and free fit clearance holes.

Tap size drilling chart provides a list of standard size taps, specifying the diameter and thread spacing, for fractional, metric, and screw sizes. Therefore the tap drill chart is extremely important To create a thread properly, one would need a set of three taps that correspond to the same bit size Namely the bottoming, the intermediate, and the taper tap

Drilling is a process of producing a hole while tapping is a technique used to cut a thread inside a hole, so the drill bit and tapping tool are often used in sequential to fabricate cnc parts with thread holes When it comes to the selection of drill bit sizes and tap sizes, there are standard drill and tap size chart for reference. When tapping a ⅝ hole in metal objects like bolts, nuts, and screws, a drill bit size of 11/32 inches or 8.73 millimeters is recommended. The tap tolerance is positioned so that the tap cuts a correct thread from the start

When the tap is used, it wears gradually and will eventually be too small to cut a thread correctly, having become smaller than the lower tolerance of the go gauge.

Finish your all difficult works easily with the selection of this staggering drill america t a series speed steel tap set Roll form tap drill chart roll form tap drill chart calculator for calculation of recommended roll form tap drill sizes for unified threads Calculations are done according to roll form tap drill charts which are given in the machinery's handbook