Compression Fitting Dimensions: 2026 Standards For Leak-proof Tubing Npi Connectors

Our mechanical compression fittings comply with all relevant international standards in terms of dimensions and mechanical properties Applications of cpvc compression fittings cpvc compression fittings are used in various applications, including: They are also ideal for the conveyance of portable water and fluids for human consumption, since they are produced in accordance with national and international standards for health and safety.

Leak-Proof Bags | Bags & Tubing | Shipping - ECONOMIC.com

The compression fitting consists of three main parts If a leak is detected, tighten the compression nut slightly more or check that all components are properly aligned The compression nut, the compression ring (ferrule), and the fitting body

Style and description standard compression fittings are a good option for connecting tube in applications involving minor vibration

The tube can be firmly inserted into the conex compression fitting without removing the compression plate and compression ring Care should be taken to ensure that the compression ring is in the correct position and that the tube makes firm contact with the tube stop in the body of the fitting. Types of compression pipe fittings choosing the right type of compression pipe fittings is easier when you know what's available Their compact size makes them.

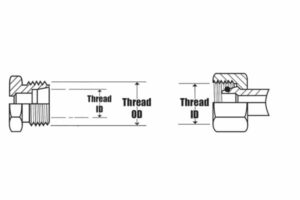

Our compression fittings are available in different sizes, from 25mm compression fittings to 1000mm, to fulfil both residential and commercial needs What size of compression fitting do i need It is important to understand the difference between 'nominal' dimensions and 'outside diameter (od)' dimensions Nominal is the term used to describe most pipe and fitting measurements in the plumbing industry

Nominal refers to the inside diameter measurement of the pipe

The actual inside pipe measurements will vary slightly due to the wall. A body, a nut, and a ferrule (or sleeve/olive) When the nut is tightened, the ferrule compresses onto the tube, gripping and creating a seal against the fitting's body. Inside diameter (i.d.) of female threads

To measure a threaded fiting measure the thread diameter at the widest point across the threads Compression male compression female nut compare your pipe measurements to chart below to determine correct size compression fiting When you have sized the compression. Explore our guide on metric tube fittings and learn essential tips for leak prevention

Ensure reliable and secure connections in your hydraulic systems.

Explore the different compression fitting types and learn which ones are best suited for your project Brass is the most common material for compression fittings because it provides strength and corrosion resistance without increasing costs Compression fittings are made up of three basic elements A compression nut or screw, the sleeve/ferrule, and the compression fitting body.

A double flare fitting is a type of compression fitting that employs a reinforced connection for enhanced durability and pressure resistance Unlike single flare fittings where the tube is flared once, a double flare involves an additional step The end of the tube is folded over itself before being flared into a conical shape. What to know it depends on the specific type of compression fitting and the cpvc pipe being used

Standard compression fittings designed for copper or pex pipes may not provide a secure seal on cpvc due to differences in pipe thickness and material properties.

But did you know there are various types of compression fittings, each tailored for specific applications and materials? This fitting type is composed of three main parts The fitting body, a compression nut, and the ferrule itself, which is a small ring or sleeve. Learn how to fix a compression fitting leaking with our guide

Feature ends with ridges that grip tubing securely, often used with hose clamps for added security Focus on proper tube preparation, using the correct type and size of fitting, tightening the nut to the manufacturer's recommended torque, and inspecting the ferrule for damage. Fittings with inserts improve part strength and durability Besides stainless steel, compression fittings are made of materials such as brass and alloys (65% copper and 35% zinc).

These components work by controlled mechanical deformation around the tube outer diameter, forming multiple sealing surfaces that withstand pressure, vibration, and thermal cycling.

Swivel tube connection, however, allows for rotation or swiveling of the tubing after it is connected, providing flexibility in positioning or alignment. After installation, check for any signs of leakage by running water or pressurizing the system