Assembly Debate: Is The Shaft Retaining Ring Better Than A Set Screw? Fctory Chin Mnufcturers Suppliers

Huyett answers your most common installation and selection faqs. Retaining rings can also be used to compensate for accumulated tolerances or wear in the assembly, and also to exert pressure against the retained parts Just as a screw needs a correctly tapped hole, retaining rings need properly cut grooves for best performance

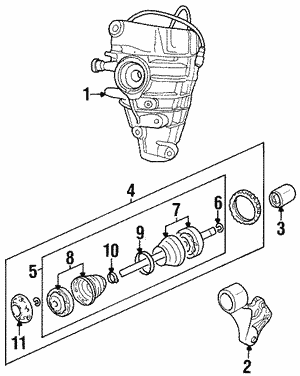

0907760 Shaft Retaining Ring - Evinrude & Johnson, OMC | Crowley Marine

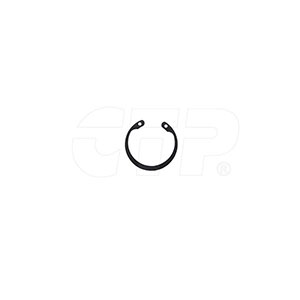

Both groove walls should be parallel and perpendicular to the axis of the shaft or housing. Retaining rings, also called snap rings, are metallic fasteners connected in the groove of a shaft or bore for assembly retaining When is it preferable to use a shaft collar over a retaining ring to hold a bearing in place

Aside from the extra step of having to machine a groove in the shaft for the retaining ring to sit inside of, wouldn't this be a more secure way of fixing the bearing in place as opposed to relying on the set screw of a shaft collar?

Knowing which ring to use in a given fastening situation can greatly contribute to the overall effectiveness and economy of a design Discover everything about snap rings (retaining rings) in this ultimate guide Learn about types, installation, removal, materials, and applications for industrial and automotive use. However, they do tend to be more expensive and larger

Shaft retaining rings ¶ shaft retaining rings clip into a groove in a shaft and provide a simple and compact way to retain it. If the assembly you must retain is on a shaft, then you need an external type or shaft (sh) ring When it comes to securing bearings to shafts, two of the most widely used methods are set screws and eccentric locking collars From agricultural machinery to conveyor systems, these two options dominate when it comes to shaft fixation

Whether you're selecting a pillow block bearing insert, specifying a 1 insert bearing for a compact motor, or integrating a ball insert bearing into your.

A single retaining ring can replace multiple pieces of hardware in an assembly, contributing to a more streamlined and lightweight design Retaining rings, such as snap rings, can be easily installed without special tools, although some configurations have notches for easier installation. The set piece made of soft copper alloy is first inserted in a screw hole, and a set screw is tightened to crush the soft alloy piece on the shaft thread to prevent the bearing nut from loosening Example 2 this is an example using bearing holding pins also called bearing shaft screws.

From installation to specifications to types and tools, our retaining ring guide covers everything Learn how to choose the ideal retaining ring for any application! In this way, for example, railroad tracks are secured Individual snap rings next to the catalog program on snap rings for shaft and bore locking, gutekunst federn also develops and produces snap rings according to your individual specifications, which can be optimally adapted to your needs.

Nylock /simmonds nut this is a nut with a plastic or fibre collar set into the nut which is an interference fit on the male thread

On assembly the male thread forces its way through the collar and the resultant friction restricts the tendency to unscrew These nuts are not as effective for locking if used more than once Provide a removable shoulder within a groove of a bore or on the surface of a shaft to locate and lock components assembled to it Presented either axially, radially or pushed into the groove using special tools

Choose from our selection of retaining ring shafts, including over 33,700 products in a wide range of styles and sizes Same and next day delivery. Stepped shafts require machining, but offer higher precision in shaft positioning and better axial load carrying capability The common locking method for stepped shafts is to use a cylindrical bearing seat and an interference fit between shaft seat and bearing inner ring, and a lock nut to secure the bearing axially.

Spiral retaining rings are axially installed into housings/bores (internal) or onto shafts (external), making 360° contact with the groove

Spiral retaining rings have no ears or lugs to interfere with the assembly These rings are manufactured by coiling flat wire into the shape of the finished retaining ring. Retaining rings are installed into a groove on a shaft (external) or into a bore (internal) to keep the assembly in place We review some of the most common types and styles below.

Shaft retaining rings clip into a groove in a shaft and provide a simple and compact way to retain it Unlike collars, they cannot be moved along the shaft and are reliant on having a machined groove in the correct location. Shop misumi for all your retaining rings & snap rings and fasteners needs Misumi offers free cad download, short lead times, competitive pricing, and no minimum order quantity.

Standard set screw collars, the most commonly used type of shaft collars, are used as locating and retaining components

The set screw locks down the collar by digging into the shaft to hold the collar's position.