Types Of Shaft Keyways: 2026 Industry Comparison Reveals Best Designs Part Number 2l106hdk 1 3 8" Steel Two Piece Split Collars With

Shaft key selection and keyway design should consider key types, correct fit, key material, shaft material, load, fatigue & safety factors By understanding the benefits and applications of spline shaft keyways, engineers can. To secure the hub and shaft and stop relative movement between a power transmitting shaft and an attached component, a key and the keyway combine to form a keyed joint.

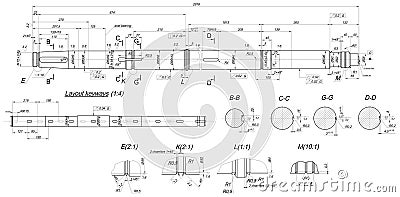

Expanded Shaft Sketch With Keyways Stock Vector - Image: 53265854

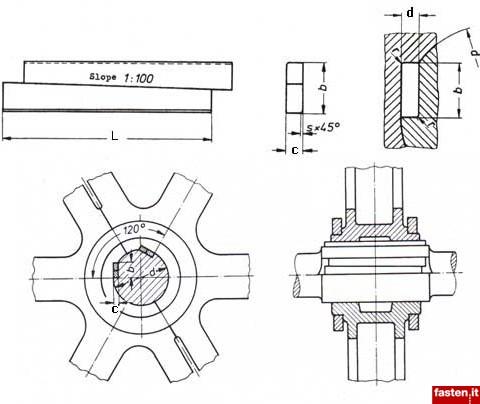

Shaft key design primarily involves two aspects Its various types and designs suit diverse applications across industries such as automotive, aerospace, and industrial machinery Dimensional design and shape design

Dimensional design is determined by the size of the shaft and the keyway, while shape design should take working conditions, environment, and load into account.

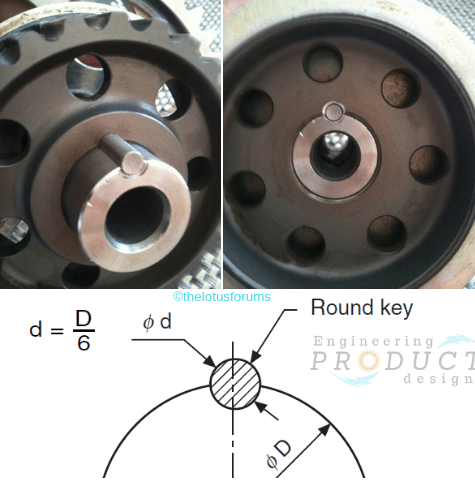

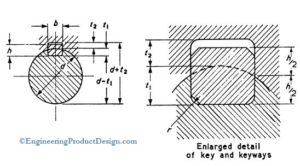

The keyway is a groove or slot that is machined into a shaft or hub to accommodate the key This recess it is usually cut into the centre of the mating surface, allowing the key to fit snugly The shape of the keyway and key varies depending on the specific application and the type of key connection being used. The design of keyways and keys is specified in standards, different designs are available but typically the contact area is flat.

In conclusion, shaft keyways are vital components in mechanical couplings, serving as the backbone for torque transmission By understanding their importance and considering key design factors, engineers and designers can create more efficient and reliable mechanical systems. Introduction to keyways keyways are essential features in mechanical design that facilitate the secure engagement of shafts and hubs in machinery A keyway is a slot or groove cut into a shaft or hub, into which a key is inserted to prevent relative rotation

This article will explain the various types of keyways, their applications, and their significance in machining

Read our latest article on the different types of shaft keys and their main purpose For other helpful articles, visit the reid supply website. Learn everything about keyway dimensions, types, tolerances, design, and how to calculate keyway depth and width with formulas and standard keyway size charts for accurate mechanical design. Safety considerations necessitate a factor of safety between 3 to 4

The key joint's design comprises a shaft, hub, and key, with slots, known as keyways, in the rotating shaft, hub, or both to accommodate the key Keyways are typically created using vertical or horizontal milling cutters, allowing the key to fit parallel to the axis of rotation. This article provides a comprehensive examination of machining keyways, discussing the various types of keyways, the methods employed to machine them, the tools used, material considerations, and common applications It also highlights the importance of keyway machining in maintaining the integrity and performance of mechanical systems, emphasizing the relationship between keyway design and.

A simple mechanical part can reduce manufacturing costs and machine downtime.

A keyed joint is a joint between shaft and hub using a key and keyway to prevent relative motion between hub and shaft to transfer power. 3.9 design of sunk key when a key is used in transmitting torque from a shaft to a rotor or hub, the following two types of forces act on the key Forces (f1) due to fit of the key in its keyway, as in a tight fitting straight key or in a tapered key driven in place These forces produce compressive stresses in the key which are difficult to determine in magnitude.

This article provides a comprehensive examination of machining keyways, discussing the various types of keyways, the methods employed to machine them, the tools used, material considerations, and common applications. A comprehensive overview of keyways, how they function, and the key and keyway dimensions/sizes involved in their design. In this video, we break down huey, pinhead, pintex, and revolver, comparing their strengths, weaknesses, and. Keyways are an essential part of shaft design, used to connect and lock rotating components like gears, pulleys, and couplings to the shaft

They help in transmitting torque, preventing slippage, and allowing easy removal of parts.

The utility patent # is 7665337 and is protected through feb 18, 2029 The design patent for the bow shape is protected until jun 20, 2026 Features a patented under groove in the keyway design protected against cloning by utility patents until july 20th, 2014 Us 5,715,717 and us 5,809,816.

Shaft keys are important machine components designed to transmit torque and rotative force There are several types of shaft keys, each with their own particular role and application Here we look at the different types Shaft keys, shaft key design, rectangular keys, square keys, woodruff keys, gib keys, taper keys.

Design is more than just making things look pretty

It's about conceiving and planning what doesn't exist yet—transforming ideas into reality through thoughtful creation Understanding the vast landscape of design specialties can open doors to new opportunities and help you determine where to focus your creative energy Whether you're just starting out or looking to […] Standard key and keyway sizing english dimensions:keyway

Conclusion the spline shaft keyway plays a vital role in power transmission, offering a secure and efficient connection between rotating shafts and other mechanical components