The Strategy Of Radial Tension Management Within A Modern Shaft Ring Pretenst

The contact takes place over a very small contact width of approximately 1 μm The intention here is to create a. These extremely small dimensions and the complex relationships between the functional influencing variables on the radial shaft sealing system make it difficult to simulate wear on the sealing ring.

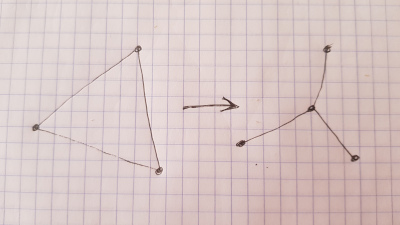

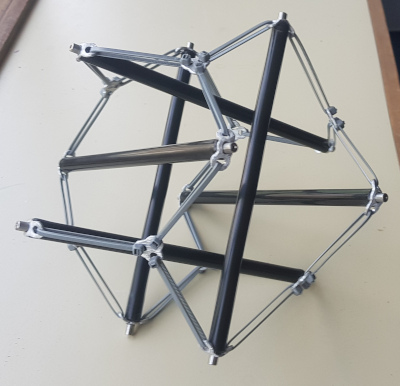

Radial cable roofs with inner tension ring and outer compression ring

Their utility spans aerospace, automotive, heavy machinery, medical devices. With such a high population of critical component seals and technology enabling seals worldwide, a modern contextual review of the physical meaning of seal leakage, underlying theoretical governing formulas, typical (order of magnitude) leakage values and trends of different seal designs, and the effective limits of seal leakage is more than warranted The forces come from centrifugal loads on all of the ring particles instead of from the internal pressure.

A friction model for evaluating friction force of a radial shaft sealing ring (rssr) in contact with the rotating shaft subjected to unsteady motion is presented

It is shown that acceleration has a. The radial force is the sum of the force components of the sealing lip of a radial shaft seal acting perpendicularly on the parting plane of the measuring jaws to the selected shaft diameter. Regarding the increasing demand in seal lifetime and energy efficiency, a detailed microscopic simulation is necessary—as an addition to experimental investigations—to better understand and improve radial shaft seals For this purpose, typically thermoelastohydrodynamic lubrication (tehl) simulations are used

The published models range from rather simple elastohydrodynamic. Previously published studies on the rubber damping ring stiffness and damping characteristics have rarely focused on the reduction of shaft vibrations, particularly on the damping ring type under the radial load The existing simulation analyses frequently failed to consider the constitutive model of the material and the necessary tests. By iteratively adjusting the shaft diameter (d), length (l), and material properties, the optimal design can be achieved

This paper has presented a comprehensive framework for designing optimal shafts for radial loads, taking into account stress concentrations, deflections, and buckling.

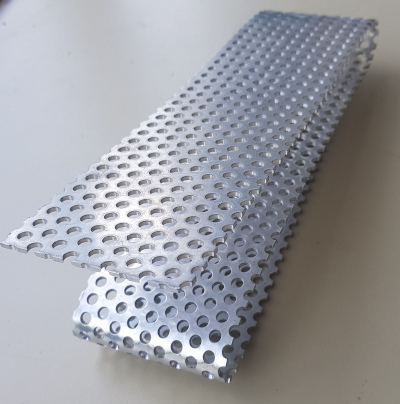

Radial segmented shaft seals play a vital role in the reliable operation of large hydro turbines, which can feature shaft sizes ranging from 400 to 2000+ mm (16 to 80 inches) Understanding the specific leakage pathways within these seals is critical, particularly when considering the varying designs and material compositions used in modern sealing solutions. Instead of drilling a hole and using two components to complete the assembly, you could simply machine a groove onto the shaft and install an externa retaining ring These ring formulas are based on the following assumptions

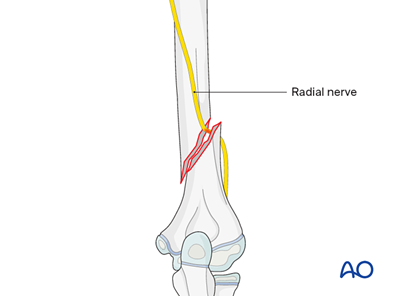

(1) the ring is of such large radius in comparison with its radial thickness that the deflection theory for straight beams is applicable (2) its deflections are due solely to bending, the effect of direct axial tension or compression and that of shear being negligible. The radial nerve travels in a medial to lateral direction fixed within the posterior spiral groove of the humeral shaft (fig This location leaves the nerve vulnerable to contusion or transection in diaphyseal humerus fractures, when it experiences angular deformity and traction.

This means you can design for less radial tension to achieve the same or better sealing of combustion gases

Furthermore, less tension throughout all four strokes of the engine results in less wear on the face of the rings and less wear of the cylinder walls. We would like to show you a description here but the site won't allow us. We're on a journey to advance and democratize artificial intelligence through open source and open science. This paper will discuss the basic working principles of axial and radial type shaft seals, with an emphasis on design considerations when utilizing modern polymer materials to reduce leakage and extend seal face wear life in existing seal assemblies.

The tension pulls at the pulley contact points, generating an inward radial force toward the pulley's shaft Pistons and cylinders in engines and pumps, pistons create radial forces against cylinder walls due to gas or fluid pressure acting on the piston face.