The Strategic Structural Integrity Analysis Of A Heavy-duty Key Shaft How To Chieve Efficiency In Mngement

Best practices for mine shaft integrity assessment drawing from extensive industry experience, several best practices have emerged for assessing the structural integrity of mine shafts. Featuring a solid steel shaft and wide helix, these anchors easily penetrate tough soil and provide maximum holding power for swing sets, tents, and more. Tight fit key / key slot k s = k a k d / k f slide fit key / key slot k s = k a k d / k w where

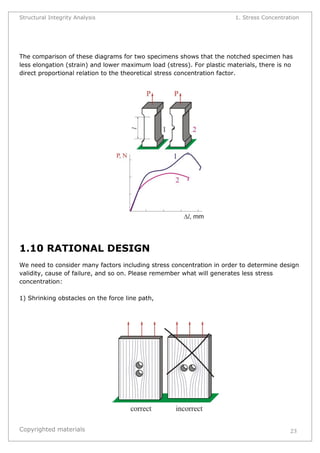

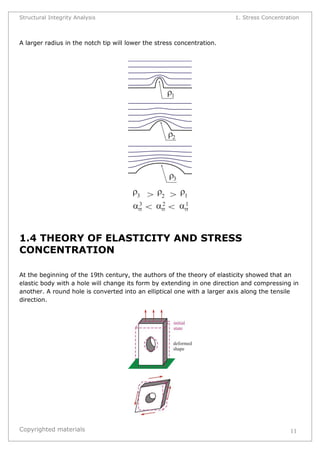

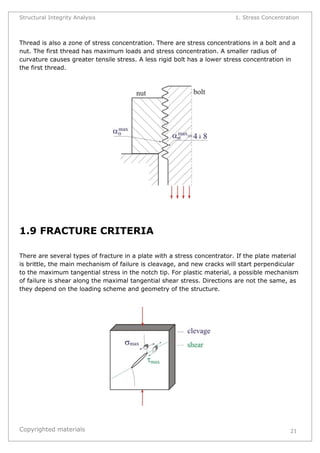

Structural Integrity Analysis. Chapter 1 Stress Concentration | PDF

Τ = shear stress s s = yield stress of key t = torque f = force d = shaft diameter w = width l = length k s = service factor k a = application factor k d = keyway application factor k f = fatigue life factor k w = wear life factor f s = design. Third chapter records for problems in motor rotor shaft design forth chapter records force analysis of motor rotor shaft and detail standard design procedure of combine twisting and bending moments of shafts. In this paper kennedy key is discussed and analysed in detail

The kennedy key consists of two square keys

The hub is bored off the centre and the two keys force the hub and the shaft to a concentric position Kennedy key is used for heavy duty applications The analysis of the kennedy key is based on two criteria which are failure due to shear stress and failure due to compressive stress. Structural integrity is a key component of modern engineering contributing for the safe and reliable performance of a variety of engineering structures in different sectors e.g

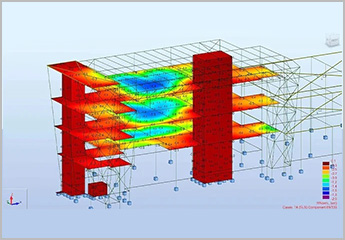

Aerospace, automotive, civil and industrial manufacturing. This study investigates the damage observed in shaft, key, and flange within gearbox assembly through a combination of visual inspection and finite element analysis (fea) The evaluation process emphasizes achieving a clear fit between the shaft and flange, which is further analysed through a parametric study involving various interference fits Fea simulations are conducted using nx nastran.

The integrity of shaft keys and keyways is critical in mechanical systems, particularly within rotating machinery applications

Failures of rotating equipment often cause severe consequences, so it is necessary to study their integrity and life as detailed as possible, especially when crack is detected In the case studied here, hydro power plant turbine shaft is analysed by using fracture mechanics parameters both for static and dynamic loading in order to assess its structural integrity and life Structural integrity testing is a cornerstone of modern engineering, ensuring that buildings, bridges, aircraft, and other critical structures can withstand the forces they encounter during their lifespan Whether you're an engineer, architect, or project manager, understanding the nuances of structural integrity testing is essential for delivering safe, reliable, and durable projects

(sia) is a leading engineering and consulting firm dedicated to the identification, analysis, and prevention of engineering failures to support the reliable operation of critical infrastructure. A failure incident involving forklift forks at a plywood manufacturing plant led to a detailed analysis of the operational conditions and structural integrity of the equipment Investigation revealed abusive service conditions as the primary cause for the initiation of fatigue cracks in the forks. Whether used in construction machinery, industrial equipment, or automotive drivetrains, these components endure extreme stress and play a crucial role in ensuring seamless mechanical power transmission.

This proactive approach helps avoid structural degradation that can threaten business operations and increase insurance liabilities.

Fatigue analysis utilized finite element analysis (fea) techniques via ansys workbench Overloading significantly reduces drive shaft life, with 20% and 30% overloads also yielding infinite life In the context of gudgeon bolt screw conveyors, this bolt plays a pivotal role in maintaining the structural integrity and operational efficiency of the conveyor system It is specifically designed to withstand the mechanical stresses typically encountered in screw conveyor operations, including rotational forces and material load variations.

Finite element analysis (fea) validates structural integrity under peak loads This comprehensive analysis reveals key trends, growth drivers, and leading companies shaping this sustainable packaging sector Explore market size projections, regional breakdowns, and future opportunities in this expanding industry. Straightening presses correct bends in metal parts like shafts, plates, and beams

Hydraulic presses offer precision and versatility

Specialized types target shafts or plates Choosing the right machine ensures quality, efficiency, and cost savings in manufacturing and repair. But what exactly makes a metal building heavy duty Second chapter elaborates extensile literature survey regarding analysis of rotor shaft problems and finite element analysis aspects