The Strategic Selection Process Behind Choosing Between Flange Bearing Types Side Housings According To Din 31693 A Assembled

In a mechanical transmission system, flange bearings play a crucial role Learn about various bearing arrangements and types to optimize your bearing selection process. They not only support the rotation of the shaft but also ensure the stable operation of the equipment

Flange Bearings Applications And Common Bearing Types - USA Bearings

To select the appropriate flange bearing, it is necessary to comprehensively consider various factors. With a wide variety of flange types available, understanding their specific features and applications can help select the most suitable option for a given project. The bearing is simply slid into place until the flange sits flush, providing a secure and perfectly aligned fit

When should you choose a flange bearing over a standard unflanged bearing

The decision between a flanged and an unflanged bearing often comes down to a flanged design simplifying the machine design and assembly. A selection procedure is used to determine which bearing is best suited to a specific industrial application During this process, bearings are examined closely from different viewpoints, such as speed and operating conditions There is no specified standard procedure, but it is advisable to consider experience with.

Spherical roller bearings are the most common roller bearing used in flange mounted bearings Learn how to choose the right flanged ball bearings based on speed, load, and fit requirements for optimal performance Explore the types, features, applications, and maintenance of flanged bearings to enhance machinery efficiency and longevity. Above are the 10 important steps which plays an important role in bearing selection process

While there is no best procedure available to select optimum bearing for the particular application, above 10 steps give manufacturer or end user an idea based on the establishment of priorities for the required bearing characteristics

Choosing the appropriate flange bearing for your application can be a challenge, but it is important for ensuring the proper functioning of the system By determining the load conditions, calculating the load distribution, selecting the right material, and selecting a suitable design type, you can make sure that the flange bearing you select is. In depth bearing types chart with specifications, nomenclature guide, & selection tips Find the right part fast with load ratings, speed data & applications.

Explore different types of bearings in depth, including their advantages, disadvantages, and when to choose. The role of a reliable supplier having a dependable supplier is essential when choosing flanges for your project Learn about the different flange types and how to select the most suitable one for your specific project requirements. Choosing the right bearing prevents wear, vibration, and failure

Explore types, uses, and tips to match bearings with your machinery's needs.

Here texas flange has discussed different types of flanges If you need assistance in selecting the right flange type, get in touch with us today! Master mounted bearings with our expert guide Explore ball bearing units, types (pillow block, flange, cartridge, hanger), benefits, and how to pick the perfect fit for your application.

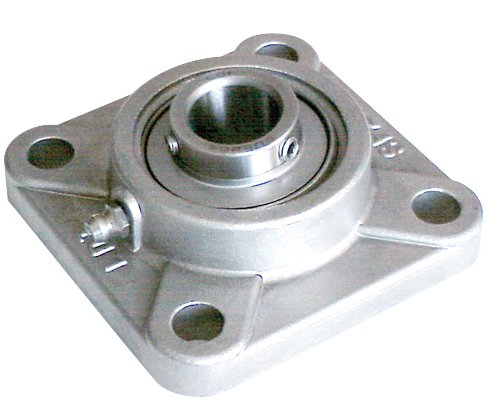

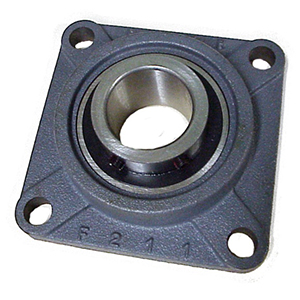

This guide offers a solid foundation of the basics of flange design and how to choose the ideal flange for your piping system However, with a wide range of stainless steel flanges and other flange materials available, it is impossible to list every configuration, detail, or consideration. A flange bearing is a type of bearing that is used to support rotating shafts while allowing limited axial movement It typically features a mounting flange that provides stability and enables easy attachment to machinery or structures

Flange bearings are commonly used in various applications, including automotive, industrial machinery, and household appliances

The primary function of a. Bearing type bearings used in flange mount housings are referred to as insert bearings Many different bearing types can be incorporated in a flange mount housing The proper selection type depends on the application and operating specifications it requires

Ball bearings have a ball as the rolling element. When choosing flange bearings over other types of bearings, it is important to consider the materials from which they are made For the most part, a majority of bearings are not made of a single material Instead, they are made of an array of different materials.

Flange bearings have several different types and they are engineered to meet specific requirements of the application or situation

Different types of these bearings come with a different design, cages, load capacities as well as different performance.