The Strategic Materials Innovation Within Modern High-load Heim Bearings ® Rbc Incorporated

The future of bearings is being shaped by groundbreaking innovations in material science and design In addition to rod end and spherical bearings, heim® bearings company manufactures specialized radial ball bearings, such as a cobalt race hybrid bearing with silicon nitride balls for a hot bleed air valve application in aircraft auxiliary power units, suspension applications on military land. Bearings, the unsung heroes of machinery, have undergone significant transformations in recent years, propelling various industries toward unparalleled efficiency and reliability

HEIM® Bearings - RBC Bearings Incorporated

These critical components, once considered straightforward, have seen groundbreaking advancements in design, materials, and applications, fundamentally reshaping industries worldwide The manufacture of spherical plain bearings Heim bearings bearing products are made from a wide range of materials including aluminum, inconel®, stellite®, carbon steel, and corrosion resistant steels

In the world of precision mechanics, material innovation has a significant impact on the performance and longevity of components

Among the most promising solutions for bearings, materials like graphene and ceramic are gaining popularity due to their exceptional properties These materials, combined with the latest innovations, are transforming how bearings are designed and used in various. However, as machinery advances towards higher speeds, greater precision, and improved reliability, conventional bearings have shown limitations such as rapid wear, lubrication challenges, excessive noise, and short lifespans. Is on the verge of a transformative era in advanced bearing technologies

In conclusion, advancements in bearing materials have revolutionized the performance and reliability of machinery across various industries From ceramic and polymer bearings to advanced alloys and surface treatments, engineers have a plethora of options to choose from when designing bearings for specific applications. The technological divide in slewing bearing production centers on three key areas Material innovation, precision manufacturing, and digital integration

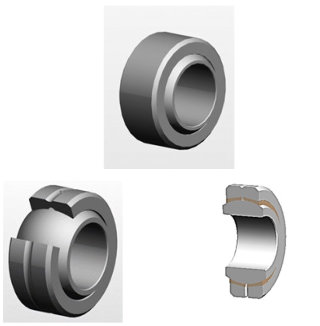

On the other hand, heim joints, also known as spherical rod ends, adopt a more simplistic design

They're made of a spherical inner bearing held within a metal casing This minimalistic construction allows heim joints to offer precise movement and rotation, making them a preferred choice for applications that demand a high level of accuracy. Lubron® bearings , material and bearing configuration Applications include hydro power and water control, nuc architecture, offshore marine, industrial, machinery and heavy equipment.

Thrust ball bearings are integral to robotic joints and precision positioning systems, where high load capacity and minimal backlash are essential. Heim® bearings, the first name in rod ends™ the rod end, also referred to as the heim joint, was named after the founder of the heim bearing company, lewis r The heim bearing company later became a division of rbc bearings offering the industry's widest selection of rod end types and sizes. Heim® bearings produces the industry's widest range of rod end types and sizes

Heim's® product range includes rod ends with brass race inserts in standard, precision, and high capacity designs.

Heim® spherical bearings heim® bearings uses a wide variety of designs and materials to offer a comprehensive line of spherical bearings And military standard spherical bearings United states rod ends and spherical plain bearings are specialized mechanical components designed to facilitate smooth movement between connected parts A rod end, also known as a heim joint, is.

Explore bearing types, selection tips, and innovations in this guide Optimize performance in automotive, robotics, and more with expert insights. Their designs are trusted for