The Physics Of Vibration Dampening In A Precise Shaft To Shaft Coupling Rsionl Shft

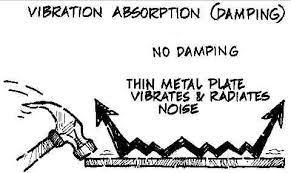

Vibration damping precision couplings in light of the advantages of elasticity, strength, resilience, and damping effects, elastomer materials are now being used in most areas of mechanical engineering The two general types of shaft couplings are: In drive technology, beyond transmitting rotary motion and compensating for misalignment between shafts, elastomer couplings (fig

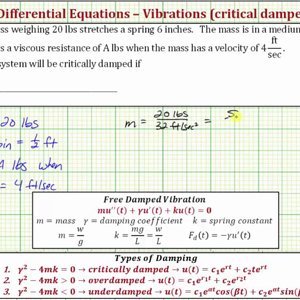

Torsional Vibration of a Shaft

1) are used to damp rotational movement, especially in areas. What are the two general types of shaft couplings The gearbox amplifies the motion of the high speed shaft relative to the low speed shaft

Gr>1 the easiest solution is to adjust the stiffness and inertia properties of one shaft to that of an equivalent shaft running at the same speed as the other shaft.

A thin layer of fluid separates the spinning shaft and stationary housing in these dampers The fluid film's pressure variations dampen vibrations and dissipate energy as the shaft rotates Stiffness, damping and handling torsional vibration That's what engineers have to consider when adjusting a flexible shaft coupling.

At higher velocities, the helicopter tail transmission system encounters notable difficulties due to excessive bending vibrations The shaft damping ring installed on the shaft system was shown to effectively suppress the shaft system vibrations In this paper, the dynamic stiffness and damping characteristics of polyurethane shaft damping rings were studied using hyperelastic and viscoelastic. The torsionally resilient, flexible coupling is responsible for effectively dampening the shocks and vibrations that occur in drive systems during operation

Due to the special spring and damping properties of the profiled coupling sleeves, elco effectively limits torsional vibrations.

Vibration dampening, system protection, and equipment longevity quality shaft couplings act as crucial protective elements within rotating machinery and industrial drive systems They provide effective vibration dampening —minimizing the oscillations that can disrupt the operation of precision components such as ball screws and linear actuators. Highly flexible shaft couplings compensating for high displacements and damping vibrations highly flexible shaft couplings are suitable for offsetting high axial, radial and angular displacements and damping vibrations and torque shocks Evolastic highly flexible couplings the highly flexible coupling evolastic with the elastomer element prestressed to pressure are capable of reducing.

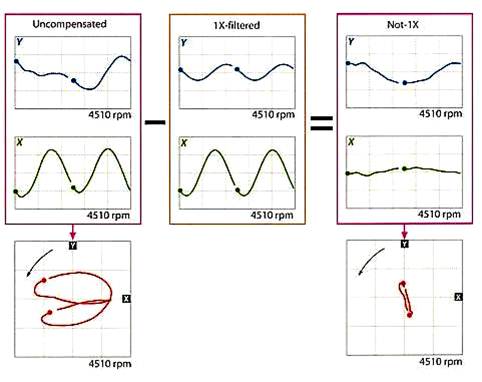

Sometimes bigger is better a customer sizing an elastomer insert coupling recently asked us if using a larger body size would provide better vibration damping In a word, the answer was, yes Vibrations in machine shafts come from a wide variety of sources. Misalignment compensation and vibration damping

Mechanical couplings are designed to accommodate various types of misalignments, including angular, parallel, and axial misalignments, thus maintaining the integrity and performance of the system.

Choose from our selection of misalignment couplings, including precision flexible shaft couplings, flexible shaft couplings, and more Same and next day delivery. Types of shaft coupling, its uses, drawings, and applications, and more also download the pdf file of this article. Coupling for misaligned shafts introduction to shaft couplings shaft couplings play a pivotal role in mechanical engineering, allowing for the efficient transmission of power between two rotating shafts

This article delves into the intricacies of couplings designed specifically for misaligned shafts Types of misalignment misalignment in shafts can be categorized into angular, parallel, and. A motor drive shaft coupling is a device used to connect the shaft of a motor to the shaft of driven equipment, such as a pump, gearbox, or conveyor Its primary role is to transmit torque while accommodating misalignment, reducing vibration, and protecting both the motor and driven equipment from damage.

Precision flexible shaft couplings come in two basic forms, both of which are designed to operate without backlash or excessive inertia while compensating for inevitable misalignment offsets between motor/gearbox and load

Torsionally stiff couplings are made with metallic flexible elements and with the intent to eliminate as much twisting deflection as possible so that the rotation of both. Ideal for demanding industrial applications requiring reliable power transmission. The specially engineered rubber compound features a unique molecular structure that effectively absorbs and dissipates mechanical vibrations across a wide frequency range. Shaft couplings play a pivotal role in mechanical engineering, allowing for the efficient transmission of power between two rotating shafts

The coupling must accommodate the specific type of misalignment present, whether axial, radial, or angular For applications prone to vibrations, a coupling that can absorb and dampen these vibrations is essential