The Mechanical Strategy Behind The Ease Of Install For A Mountable Bearing News How To Slewing Bering Correctly?

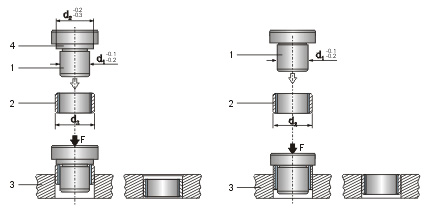

The recommended method for achieving radial retention is to create an interference, or press fit, between the bearing ring and its seat Learn more about bearing installation here. By manufacturing the shaft diameter slightly larger than the bearing bore, the inner ring is expanded during installation and thus grips the shaft

How to install a load bearing beam – Artofit

Likewise, when the housing bore is machined slightly smaller than the outside diameter of the outer ring. The way a bearing is installed and quality tested is essential to the success of any mechanical system Proper installation of bearing components this information describes the right way to install the bearing cones (inner races) on shafts (spindles) and the bearing cups (outer races) in housings to maximize bearing performance.

Bearing mounting methods depend on the bearing type and type of fit

As bearings are usually used on rotating shafts, the inner rings require a tight fit Bearings with cylindrical bores are usually mounted by pressing them on the shafts (press fit) or heating them to expand their diameter (shrink fit). A bearing by definition is a part of a machine that bears friction, especially between a rotating part and its housing The architectural definition is a structural part that supports weight

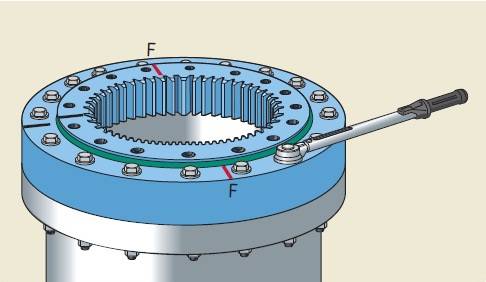

A ball bearing is a rolling element bearing that uses balls to maintain separation between the inner races Ball bearings are typically used between cantilever and rotary shafts to transfer axial or. Bearing installation procedures the installation of a bearing or sleeve into a housing bore is a simple operation when done properly Alignment of the bearing or sleeve to the housing bore is critical to prevent a cocking motion during insertion, which can damage or ruin the bearing or housing

Temperature differential installation is recommended

This page covers the installation of spherical. One of the main benefits is their ease of installation This feature can significantly reduce downtime and increase productivity in industrial settings Another advantage is their flexibility.

Correctly installing a bearing on a shaft is crucial for the optimal performance and longevity of the mechanical system The methods employed for bearing installation are often determined by factors such as the bearing type, material, and the environmental conditions where the assembly will operate This article reviews key methods for bearing installation Mounting where mounting a single direction thrust ball bearing, it is important to differentiate between the shaft washer and the housing washer

The bore of the shaft washer is ground and always smaller than the bore of the housing washer

The shaft washer should always be placed against a shaft step or fixed shaft component. Bearing mounting is essential to ensure the proper operation of mechanical equipment By properly mounting bearing, they can effectively support and guide the rotational or linear motion of a shaft. If the installation is incorrect, the bearings will be damaged prematurely, which may affect the machine experience, increase noise and heat, or cause the machine to shut down and cause property damage

, causing health hazards to users This blog aims to introduce some key points and techniques for bearing installation and removal. The installation of a bearing or sleeve into a housing bore is a simple operation when done properly Alignment of the bearing or sleeve to the housing bore is critical to prevent a cocking motion during insertion, which can damage or ruin the bearing or housing.

This page provides guidance on the proper installation of bearing components to ensure optimal performance, reliability, and longevity.

Why are bearings frozen before installation bearings are critical components that allow machinery to rotate smoothly They are widely used in automobiles, household appliances, and industrial equipment I am a 7 year trader into the game I trade with ftmo, alpha capital and fundednext

I trade a simple, proven and mechanical 4h strategy that allows me and 100's of my members to get funded and. Bearings are an integral part of a machine's moving components and reduce the amount of friction on rotating parts In most cases, bearings fit tightly into their housings,. Video shows the installation of a frozen wheel bearing and hub assembly in a steering knuckle

We carefully line up the bolt holes on the steering knuckle wi.

If you need to install a bearing or a sleeve into a press fit environment, some heat or some cold can make your job immensely easier It's science in the garage! Properly designed thrust block involves much more than dumping a load of concrete behind a bend The design involves consideration of undisturbed soil, soil bearing strength, test pressure, pipe size, fitting configuration, and trench depth to determine the bearing area of the thrust block.

Analyze bearing performance in an application with timken ® syber ® bearing system designer a powerful software tool that combines calculators and configurators to assist you with application design, bearing selection, installation, and troubleshooting Installation media, such as a usb flash drive, can be used to install a new copy of windows, perform a clean installation of windows, or reinstall windows Press the stationary seal seat firmly into counter bore ensuring it is bottomed out and squared to the shaft Use a piece of plastic between the face and the press or a plastic installation tool when using a press to install the seat