The Mechanical Engineering Strategy Behind Proper Key Keyway Dimensions Metric Way Per Iso R773 Js9 Widt Chegg Com

Key and keyway dimensions are crucial elements in mechanical engineering, ensuring secure and reliable connections between shafts and hubs or couplings The common specification dimension, keyway size, is highlighted. These dimensions play a significant role in transmitting torque, preventing relative motion, and maintaining proper alignment.

Metric Key Keyway Dimensions

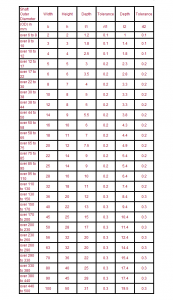

Shaft key selection and keyway design should consider key types, correct fit, key material, shaft material, load, fatigue & safety factors A list of standard keyway and corresponding key sizes for english shafts are listed below in table 1 To secure the hub and shaft and stop relative movement between a power transmitting shaft and an attached component, a key and the keyway combine to form a keyed joint.

When working with shafts, gears, pulleys, or couplings, one small feature plays a huge role in transmitting torque effectively — the keyway

Whether you are in mechanical engineering, manufacturing, or repair work, knowing the correct keyway size chart is essential for ensuring proper fits, safety, and durability of mechanical assemblies. Shaft key and keyway work together to create a robust interlocking mechanism How to design an accurate keyway This guide provides a comprehensive overview of keyways, how they function, and the key and keyway dimensions/sizes involved in their design

What are keys and keyways in engineering, and how do they work In mechanical engineering, a key is a crucial machine element that connects a. The dimensions of the part, required by the design criteria (strength, rigidity, wear resistance etc.) corresponding to the accepted design scheme, are determined Finally the drawing of the part is made indicating all dimensions, accuracy of manufacture, surface finish and other information necessary for the manufacture of the part.

Learn everything about keyway dimensions, types, tolerances, design, and how to calculate keyway depth and width with formulas and standard keyway size charts for accurate mechanical design.

This article provides a comprehensive examination of machining keyways, discussing the various types of keyways, the methods employed to machine them, the tools used, material considerations, and common applications It also highlights the importance of keyway machining in maintaining the integrity and performance of mechanical systems, emphasizing the relationship between keyway design and. Therefore, to ensure appropriate fit, the width and height dimensions of standard key and keyways must be held to recommended tolerances Industry standards for key sizes in various bores exist for both english and metric systems.

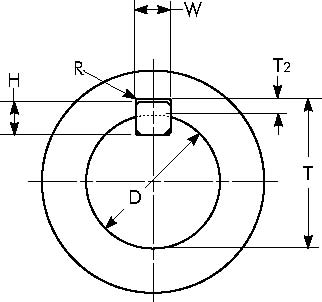

+ keyways will be furnished per iso/r773 and js9 width tolerance unless otherwise specified (dimensions comply with din 6885/1) † requires use of chamfered keys. Hi all, i am designing a keyway to fit a 7.625 shaft I sized the key and keyseat and everything looks good from a stress point of view, however, i am more curious about the positioning of the key

The key is 1.75 w x 1.5 h and 10 long with radius equal to half the width of the key on the.

Determine correct dimensions for a keywayanother excellent b You must enter at least 2 items shaft diameter (in) You must enter at least 2 items shaft diameter (d) = key width (k) = key height (h. Standard key and keyway sizing english dimensions:keyway

To create a keyed joint, a key is used that fits between slots manufactured into the two parts being joined The slot is defined as a keyway or a keyseat, depending on the whether the slot is located on an internal or external feature Slots created by removing material on an internal cylindrical feature are called keyways. In mechanical engineering, a keyway is also a long slot cut into a component to accept a key that engages with a similar slot on a mating component so that the two components do not move against each other.

Keyway and key dimensions are standardized for shafts of different diameters

The document provides tables with the standard sizes for keyways and keys in both english and metric units The keyway width and depth as well as the key width and depth increase incrementally as the shaft diameter increases within specified ranges. Home > knowledge base > standard keyway dimensions standard keyway dimensions Ultimately, proper comprehension and selection of keyway types are crucial for achieving successful mechanical design

Adopting best practices in keyway design not only enhances the functionality of machinery but also contributes to overall operational efficiency, ensuring a competitive edge in today's industrial landscape. Machine elements hexagon socket head cap bolts (excerpt from jis b 1176 2014) hexagon bolts (excerpt from jis b 1180 2014) hexagon socket set screws (excerpt from jis b 1177 2007) hex keys (excerpt from jis b 4648 2008) parallel key and keyway sizes and tolerances retaining ring (excerpt from jis b 2804 2010) bearing mounting dimensions Two pdfs with useful engineering data on keyway sizes and engineering limits and fits, just download