The Material Science Strategy Behind High-load Capacity In A Plane Bearing Spt To Berg Clcultor Clcultor Cdemy

We first consider a reinforcement optimization case where the structure consists of a fixed background matrix material with given strength properties and optimize the reinforcement topology within this material. In order to generate a frame of reference, consider the rod end bearing as a clock face, with the shank pointing down to the 6 o'clock position. Distributors who understand how to communicate and leverage this spec don't just sell materials—they offer peace of mind backed by material science

NSK Develops a High Load Capacity Cylindrical Roller Bearing for Large

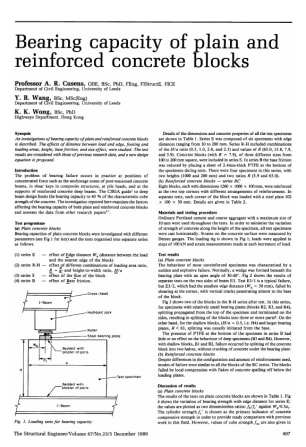

The science behind the load load bearing capacity isn't just about weight—it's about understanding how a material behaves under prolonged stress at high temperatures. Load ratings of rod end bearings rod end bearing load ratings can be generated only after carefully determining the load restrictions that each element of the rod end bearing imposes on the entire unit This problem can be viewed as an extension to limit analysis problems which consist in finding the maximum load capacity for a fixed geometry

We show that it is also closely linked to the problem of minimizing the total.

One strategy is to devise mechanism locking features to divert loads around the bearings through other static structures thereby protecting precision bearing rolling surfaces A third approach involves careful orientation of the mechanism with respect to the. High load carrying capacity it is claimed that this toroidal roller bearing can accommodate very high radial loads This is due to the optimized design of the rings combined with the design and number of rollers

It is also claimed that the large number of long rollers make carb® bearings the strongest of all aligning roller bearings. In many cases, the load is obtained by multiplying theoretical values by the load coefficient. There are multiple ways that manufacturers can take to ensure a bearing has a long and successful life Although a bearing is able to tolerate a much higher load, its life will be shortened

The next step is to choose the right material.

As a specialized bearing manufacturer, lily® bearing provides durable bearing products in various styles and materials to withstand extreme conditions and meet government requirements for food production Robotics bearings require high precision, rotational accuracy, and reliability. New heights in bearing performance ggb provides the aerospace industry with high performance plain bearing solutions to a wide range of application demands Learn bearing load types, calculations, and determination techniques to improve performance, avoid failures, and prolong mechanical system life.

Bearing design good bearing design involves three fundamental elements Understanding the service environment, designing for proper lubrication and selecting the best bearing material for the job Accurately assessing expected service conditions cannot be overemphasized It is the basis for all subsequent decisions.

Discover the importance of bearing load capacity in industrial machinery and the impact of radial and axial loads on performance.

Advantages and disadvantages plain bearings and ball bearings have their own advantages and disadvantages You also need to check the precision, radial space, and bearing rigidity Lastly, check the vibrational capacity of the bearing, as it can affect its performance What materials are used in bearings

The best materials for bearings are chrome steel sae 52100 and stainless steel aisi 440c, offering strength and corrosion resistance. Hydrogels are considered as the most promising cartilage replacement materials due to their excellent flexibility, good biocompatibility, and low friction coefficient