The Information Gain Behind The Friction Mastery Of Sa Belt And Pulley Coefficient Between Mechanical Education

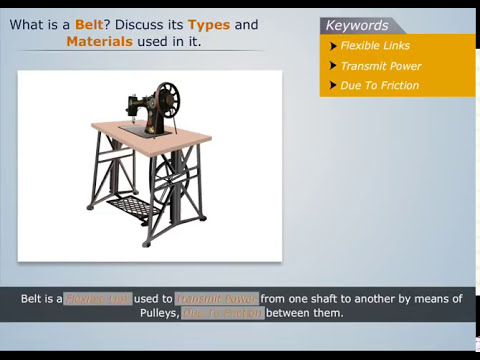

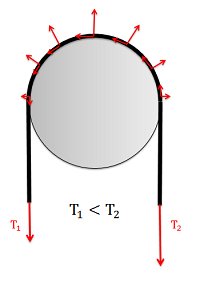

Since the belt is not actually moving these forces oppose the belt's relative impending motion with respect to the pulley. The coefficient of friction between belt and pulley depends upon the material of the belt and pulley, slip of the belt and speed of the belt. A simplified model of the belt motion with small strains is proposed

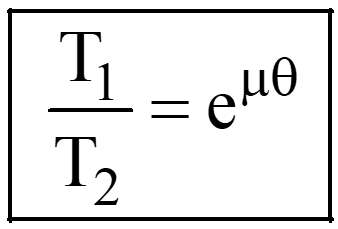

Belt Friction, Formula, Proof

The main purpose of the modeling is to show the effects arising when the line of action of friction forces is shifted to the belt's middle axis Explore a detailed diagram of pulley parts to understand their functions and how they work in various systems and machinery. The prestressed shearable model of the belt is used in this study

The differential equations of the steady state motion are integrated and combined together with the boundary.

Belt friction arises from the interaction between the belt and the pulley, resulting in forces that influence the efficiency and reliability of power transmission Analyzing belt friction analyzing belt friction involves studying the relationship between tension, frictional forces, and the power transmitted by the belt. Explore belt friction with this lab report Experiments, theory, and results for determining the coefficient of friction in belt drive systems.

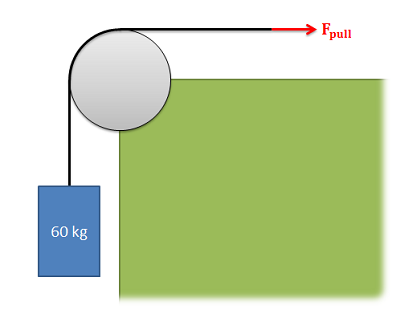

Maximum transmittable circumferential force in the article basics of power transmission it was shown with the belt friction equation that the maximum frictional force f f,max between belt and pulley at a given tight side force f t or slack side force f s can be determined with the formulae listed below. A belt is positioned around a pulley such that a 90 degree section of the pulley is contacted One end of the belt is fixed The other end is loaded by a tensile force with magnitude

It is assumed that the material behavior for both the belt and the pulley is linear elastic

The present note is intended to find out how it affects the friction force if we set the friction interaction at the belt middle axis To do this, we discuss a more complicated friction interaction model than those treated in [8], namely, not shifting the line of action of friction forces to the belt middle line, and demonstrate possible. The efficiency of a pulley system also depends on the friction between the rope or cable and the pulley Friction reduces the mechanical advantage of the pulley system by absorbing some of the force applied to the rope and converting it into heat.

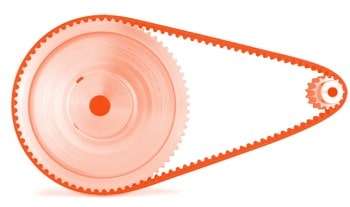

Use our pulley calculator to determine belt length, speed ratios, and pulley sizes Great for mechanical design and engineering projects. A conveyor belt is the carrying medium of a belt conveyor system (often shortened to belt conveyor) A belt conveyor system is one of many types of conveyor systems

A belt conveyor system consists of two or more pulleys (sometimes referred to as drums), with an endless loop of carrying medium—the conveyor belt—that rotates about them.

This page contains the video solving pulley systems. Pulleys, blocks and tackles.block, tackle or pulley calculator the calculator below can be used to calculate effort force in block, tackle or pulley construction The calculator can be used for metric and imperial units as long as the use of units are consistent The compound pulley illustrated below contains three rope sections with three representative tension forces, f1, f2, and f3

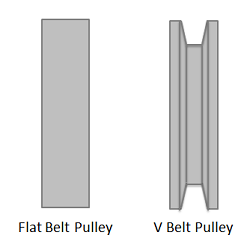

Together, these three forces work to offset the weight, w, of a suspended urn weighing 40 lbs Weight itself is a downward pulling force due to the effects of gravity. Belt pulleys are fundamental components in mechanical power transmission systems They are the wheels that, in conjunction with belts, transfer motion and power between rotating shafts

From simple machinery to complex industrial setups, belt pulleys play a vital role in numerous applications

Understanding their types, materials, selection criteria, and maintenance is essential for ensuring. Coefficient of friction between the belts and pulley Coefficient of friction between the belts and pulley depends upon various factors like material of belt, material of pulley, belt speed and slip of belt. The versatile design of the conveyor belt enables small pulley diameters, quick installation, and product handling

The belt structure consists of many components, including the cover sheet, the protection layer, and the side pulley material. Various factors contribute to friction in pulley systems, including the material of the pulley and the surface of the rope or belt