The Hidden Mechanics Driving The Precision Of Thomson Linear Motion Tech ® Systems

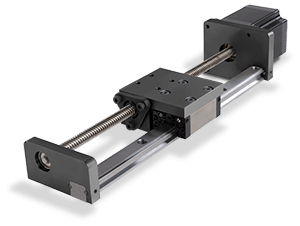

Why thomson precision linear actuators Los husillos de bolas con cilindrado de precisión ofrecen un movimiento suave, un posicionamiento preciso y un funcionamiento silencioso, mientras que los bujes de la guía de deslizamiento y el robusto diseño. Thomson precision linear actuators offer the longest stroke lengths in the industry, a simple and reliable redimount™ system to mount your own motor, and product customization options

Thomson® Linear Motion Systems

These actuators draw energy only on demand and operate more quietly than pneumatics. Actuadores lineales de precisión thomson serie t el diseño probado de los actuadores lineales de precisión de la serie t se utiliza en miles de aplicaciones por todo el mundo But few people realize that at the heart of these technologies lies something much simpler — the linear motion system

These are the unsung heroes that make precision, consistency, and speed possible across industries.

As a global leader in linear motion, thomson plays a critical role in delivering intelligent, clean and efficient motion to help customers compete and scale in a rapidly evolving world As part of altra, thomson is even more equipped to provide complete system solutions through its control, drive, motor, power transmission and precision linear motion technologies. Ball splines resist radial displacements resulting from torque loads and require smaller forces to achieve axial displacement of the spline member while transmitting torque. The evolution of thomson's 60 case shafting technology thomson's 60 case standard shafting stands as the gold standard in linear motion applications

Surface finish consistency superior roundness and straightness As part of regal rexnord 's linear motion division, thomson industries manufactures a wide range of components that help its customers build better machines to improve lives From electric linear actuators, precision screws and robot transfer units to linear guides, screw jacks and ball splines, thomson motion control solutions deliver high performance, long life and little to no maintenance. Linear units also support the drive with a guidance structure and protect the mechanism within a sealed cover (figure 1)

There are many variables that influence the selection of a linear motion system

Thomson has dedicated the past 70+ years to becoming experts in this field and providing customers with the necessary resources to make informed design decisions. One of the least expensive methods of generating linear motion from rotary motion racks can be placed end to end for as great a distance as long as one can provide a secure base on which to bolt them A new approach to linear systems design greatly reduces the time required to utilize economical and proven standard components to meet the vast majority of linear motion requirements. Ideal applications include machine tool automation and testing equipment.

The global leader in mechanical motion technology Thomson's linear motion systems range covers the smallest and most compact to the biggest and most robust. How to choose for your application. N your linear motion applications, adjustable diameter linear ball bushing bearings can help you achieve higher precision.

Lead screws supernuts thomson bsa® precision lead screws are an excellent economical solution for your linear motion requirements

For more than 25 years, thomson bsa has designed and manufactured the highest quality lead screw assemblies in the industry.