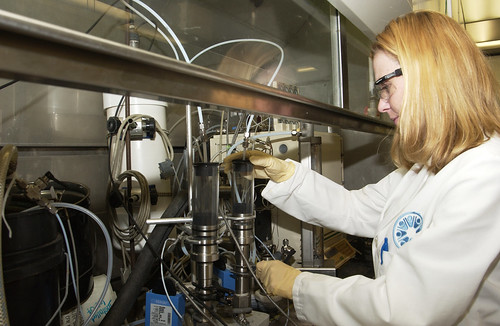

The Engineering Strategy Behind The Vertical Load Capacity Of A Pillar Bearing รูปภาพ เทคโนโลยี อุปกรณ์ อุตสาหกรรม เครื่องจักร แขน วิศวกรรม

Due to the lack of relevant specifications on the calculation method of pile foundation bearing capacity under cyclic dynamic loading, the engineering community often ensures the safety of structures by significantly increasing the design value of pile foundation bearing capacity Because they are critical to the load path, decisions about modifying, perforating, or removing them demand engineering analysis. This results in a great waste of resources.

1366x768px | free download | HD wallpaper: indonesia, surakarta

The vertical bearing capacity of a pile group is analyzed using design loads Introduction load bearing walls carry gravity loads from floors, roofs, and other walls down to the foundation—sometimes also resisting wind and seismic forces as part of the lateral system The service load is used in a settlement analysis

Click on the add button and add one new design load and one new service load, as shown in the figures below.

Case (1) vertical load on horizontal base footing resting on horizontal ground Nq, nγ are the bearing capacity factors, accounting for the shear strength of soil Sc, sq, sγ are the shape factors Dc, dq, dγ are the embedment factors

Γ is the unit weight of the foundation soil B′ is the effective footing width, defined in the following. This paper makes the following two innovations (1) based on reasonable basic assumptions, the pile is regarded as an ideal elastic body, and the soil around.

Q u = q p + q s (1) where

Several tests on the model pile under different inclined load in sand revealed that an inclination of load could noticeably reduce the ultimate vertical bearing capacity of short pile and lateral capacity of a vertical pile. To investigate the influence of lateral load on the vertical bearing capacity of helical piles and establish a calculation methodology for their vertical bearing capacity, numerical simulations were conducted using the finite element software plaxis 3d These simulations were based on previously documented indoor experiments found in the. Q all = q u / fs (6) where

The ultimate bearing capacity is divided by the factor of safety, commonly 3 or higher for foundation engineering, to calculate allowable bearing capacity Three types of shallow bearing capacity failure can occur General shear failure, local shear failure, and punching shear failure. The pile load capacity calculation will determine the ultimate load the pile foundation can take under service load condition

This capacity is also called as bearing capacity of piles.

As the maximum load is reached vertical cracks and crushing develops in the concrete shell outside the ties or spirals, and this concrete spalls off When this happens in a tied column, the capacity of the core that remains is less than the load and the concrete core crushes and the reinforcement buckles outward between the ties. The ultimate bearing capacity of a pile is the maximum load which it can carry without failure or excessive settlement of the ground The bearing capacity of a pile depends primarily on 3 factors as given below, type of soil through which pile is embedded method of pile installation pile dimension (cross section & length of pile) while calculating pile load capacity for cast in situ concrete.

Columns endure both vertical (axial) and horizontal (lateral) loads and this calculator assists in evaluating the structural integrity through considering column properties (young's modulus, moment of inertia (iy, iz), column length, and support types), as well as load values (lateral load, distance, and axial load). When planning a deck or floor, you might ask, how much weight can a 2×4 floor on 12 centers and with a 6′ span support Free online c channel load capacity calculator to determine the strength or capacity of a c channel beam. The european operations of tata steel comprise europe's second largest steel producer

With main steelmaking operations in the uk and the netherlands, they supply steel and related services to the construction, automotive, packaging, lifting & excavating, energy & power, and other demanding markets worldwide

Tata steel is one of the world's top ten steel producers The combined group has an.