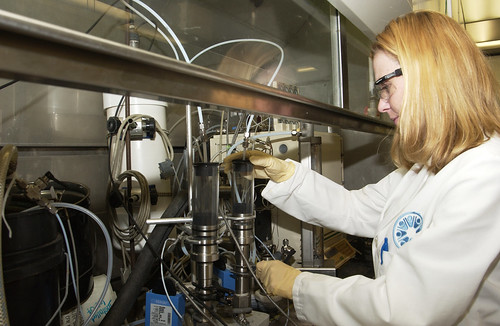

The Engineering Strategy Behind Leak-proof Seals Found In 8an Thread Size รูปภาพ เทคโนโลยี อุปกรณ์ อุตสาหกรรม เครื่องจักร แขน วิศวกรรม

A thread sealant is a material used to fill gaps in threaded pipe connections to prevent the leakage of liquids and gases These are the same thread sizes that have been used in aircraft and industrial applications for many years. What to consider when choosing a thread sealant

Free Images : boat, canal, airplane, transportation, construction

Sealing threaded pipe connections helps prevent leaks caused by. Each an size number has its own standard thread size [see column three of the chart] Formulations and use cases liquid thread sealants—often called pipe dope—come in two main flavors

By contrast, an anaerobic thread sealant applied to these same connections would cure into a hard plastic that not only seals the joint but also locks the threads in place, preventing them from loosening

When working with fluid or gas systems, selecting the correct type of threaded fitting is crucial for ensuring leakproof connections Two common types of tapered threads are national pipe taper (npt) and national pipe taper fuel (nptf) Learn what thread seals are, how they work, and why they're essential for leak prevention in threaded connections We will delve into the critical role of manufacturing tolerances, the sophisticated design of joints, the advanced properties of gaskets and sealants, and the rigorous suite of quality control (qc.

Reliable thread sealing is achieved as the anaerobic thread sealant cures in the absence of air and contact with metal surfaces creating a more reliable fit compared to conventional methods Thread sealants are ideal for preventing leaks caused by vibration, changing pressures, or changing temperatures. Thread seals have been designed to seal the threads of machine screws, studs, and similar items They are made in one piece, the rubber sealing element being molded into the metal retainer.

On the other hand, size m10x1.25 refers to the fine metric thread with a nominal diameter of 10 mm and a pitch size of 1.25 mm

Fine unified thread standard (uts) dimensions With graco's electronic injection rate controllers, closely control and monitor chemical use and collect critical operating information for reducing costs and improving processes This blog will introduce more details about an fitting size chart. An fitting size guide you can always identify an fittings based on the male thread size (outside diameter)

These sizes are constant regardless of brand, hose type, or fitting configuration Each an fitting has an established thread sizing The following chart shows the relationship between an size, tube o.d., and sae thread size A sealer is not required for an type fittings.

This is known as an thread size

Anplumbing.com the original online supplier of earls fittings Search our huge inventory of an adapters, an hose ends, an hose, and accessories for racing, marine, and aerospace applications. As mentioned earlier, you can always identify an fittings based on the male thread size (outside diameter) These sizes are constant regardless of brand, hose type, or fitting configuration.

However, understanding the sizing conventions of an fittings can be confusing, with multiple different systems used We hope that the table provided below, along with a brief history of an sizing, will be useful Below is a table displaying an. A npsm female can seal together with a chamfered nptf male.