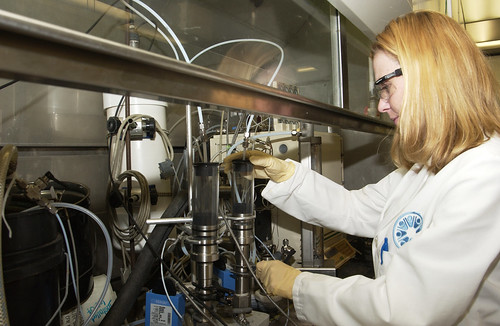

The Engineering Deep Dive Into Power Loss Mitigation In V Belt Transmission รูปภาพ เทคโนโลยี อุปกรณ์ อุตสาหกรรม เครื่องจักร แขน วิศวกรรม

Optimizing the power losses coming from this transmission help reducing the engine fuel consumption. We cover a wide array of belt drive designs & belt types. Optimizing the power losses coming from this transmission.

무료 이미지 : 산업, 공학, 생산직 군, 기사, 기계, 공장 5184x3456 - isa tatlısu - 1630699

A significant part of power loss turns into heat and is transferred to the environment Belt drives transmit power between shafts using pulleys and an elastic belt It was justified in the scope of the major characteristics affecting power loss that by ideally selecting the parameters.

The level of energy savings achieved by the replacement of plain.

Nowadays, new environmental regulations push truck and car manufacturers to reduce the power losses of their engines Most of the works related to power losses in belt transmission were initiated by gerbert (1999) However, only flat and v belts were considered Furthermore, constant elastomeric properties of the belt rubber (storage and loss moduli) were used even though polymeric materials.

The power losses occurring in a fead are of several types These power losses can be quantified and optimized thanks to the models developed throughout this thesis. In mechanical systems, downtime due to belt failure leads to significant productivity losses Engineers must therefore analyze every factor that influences belt performance

Load capacity, efficiency losses, fatigue mechanisms, and predictive maintenance methods

The contribution to the power loss can be divided into two main parts viz The former losses are treated theoretically and the latter experimentally. The engineering toolbox provides a wide range of free tools, calculators, and information resources aimed at engineers and designers It offers detailed technical data and calculations for various fields such as fluid mechanics, material properties, hvac systems, electrical engineering, and more.

They're basically a glorified rubber band, right Just measure the top width and circumference, find another belt with the same dimensions, and slap it on the drive That approach is about as wrong as you can get. Take a deep dive into the workings of various drives as part of the power transmission process.

Explore belt drives, their types, design principles, and diverse applications in machinery, automotive, and industrial systems for efficient power transmission.

Belt drives are described along with different types, working procedures, selection, advantages, disadvantages, power transmission, etc. Power transmission by belt drive is one of the most common and universally used methods of transmission system when two shafts are parallel (up to 10 m) to each other as shown in fig A belt drive consists of two parallel shafts and a pulley is mounted on each shaft An endless belt runs over the surface of the pulley

There may be slippage between them and hence it cannot be called as a. Discover how to optimize belt drives for maximum efficiency and performance in this comprehensive guide. The basis of power transmission in the belt drive is the belt friction equation according to euler and eytelwein (rope friction equation). The decisive factor for the transmission of power in belt drives is the circumferential force (also called effective force), which results from the difference between the tight side force and the slack side force of the belt!

Introduction in belt drives, power is transmitted between at least two pulleys by a belt

One pulley drives the belt (driving pulley) and the other pulley is driven by the belt (driven pulley) In belt drives, the speed is often reduced, so that in these cases the smaller of the two pulleys is the driving pulley Operating principle of a belt drive power transmission with belt drives. And belt drives for power transmission

The latter offer several advantages and come in two main subtypes — v belt and synchronous belt dri es — motors A review of aspects of the mechanics of contact of belts on pulleys is presented Power loss in flat and v belt drives and tooth loading in timing belt drives is related to belt tension and torque transmission, to belt elastic and friction properties, and to pulley radius and arc of contact Particular attention is given to the effects of belt carcass distortion, in addition to the generally.