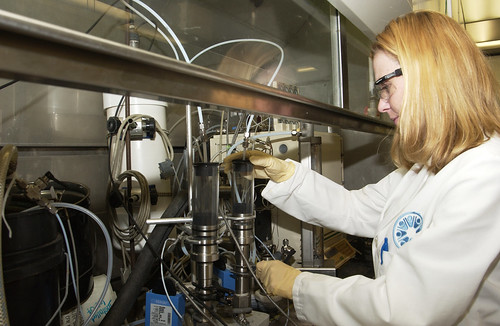

The Engineering Deep Dive Into Clamping Forces For Rigid Shaft Coupling Types รูปภาพ เทคโนโลยี อุปกรณ์ อุตสาหกรรม เครื่องจักร แขน วิศวกรรม

In addition to the answers to the questions above, some of the other design elements to consider when selecting a rigid clamp coupling for an application include 15 various types of coupling there are various types of couplings which are found being used as per the requirement Couplings are designed to fit around round, square, or hex shaft ends.

Engineering Gears Sign Business Free Stock Photo - Public Domain Pictures

Clamp or split muff or compression coupling A complete guide for engineers, students, and industry professionals. Is also known as split muff coupling

In this case, the muff or sleeve is made into two halves and is bolted together as shown in fig

The halves of the muff are made of cast iron The shaft ends are made to about each other and a single key is fitted directly in the keyways of both the shafts Geometric designs and strength checks of force couplings of shafts with hubs (interference fit, clamping connection). Types of shaft couplings have different designs and working principles each one has its own characteristics and certain applications to serve

In the following section, we will explain the various types of shaft couplings in detail. Rigid a rigid coupling permits neither axial nor radial relative motion between the shafts of the driver and driven unit When the two shafts are connected solidly and properly, they operate as a single shaft A rigid coupling is primarily used for vertical applications, e.g., vertical pump

Types of rigid couplings discussed in this section are flanged, split, and compression

Get a deep look at rigid couplings for shaft alignment Review their structure, main uses in industry, advantages, and practical advice for choosing the right type. Solid rigid shaft to shaft couplings design equations and calculator The a shaft to shaft solid coupling does not allow for misalignment, except axial, but enables the extension from one piece of equipment to another.

This document discusses different types of shaft couplings, including rigid and flexible couplings It focuses on the design of muff couplings Muff couplings are rigid couplings that consist of a hollow cylindrical sleeve and a key They transmit torque from one shaft to the other through shear resistance of the key

The document provides standard design proportions for muff coupling sleeves.

Rigid couplings connect rotating members such as shafts and transmit torque and motion Most rigid couplings are made of aluminum, steel, or stainless steel The set screws bite into the shaft to hold the coupling in place, and so may cause marring on the shaft unlike the clamping couplings A clamp coupling, also called a split coupling, utilizes bolts or clamps to securely hold the two shafts together

It offers easy installation and disassembly, making it suitable for applications with frequent shaft alignment adjustments. Drive shaft coupling types introduction in the world of mechanical engineering, drive shaft couplings play a crucial role in transferring torque and rotational motion between two shafts There are various types of drive shaft couplings, each designed to suit specific application requirements In this article, we will explore different drive shaft coupling types and delve into their unique.

Shaft coupling types a shaft coupling is a device used to connect two shafts together at their ends for the purpose of transmitting power

There are various types of shaft couplings available in the market, each designed for specific applications and conditions In this article, we will discuss in detail the different types of shaft couplings, how to select or customize the appropriate shaft. Rigid shaft coupling types introduction to rigid shaft couplings rigid shaft couplings are essential components in mechanical systems, offering a means to connect two shafts, enabling the transmission of torque and rotational motion Flanged couplings flanged couplings consist of two separate flanges, one attached to each shaft

These flanges are then bolted together to form a rigid connection. Shaft couplings are essential components for various machines This article discusses what shaft coupling is, function, and different types. Visual representation of shaft coupling what are the three types of coupling

Couplings can be broadly categorized into three types

Rigid, flexible, and fluid couplings Rigid couplings provide a solid and fixed connection between two shafts, ensuring alignment and minimal play. Choose from our selection of rigid shaft couplings in a wide range of styles and sizes Same and next day delivery.

What are the three types of coupling The three fundamental types of coupling are rigid couplings, flexible couplings, and fluid couplings These categories encompass a wide range of specific coupling designs, each suited to particular applications and operational conditions What coupling is used to connect two shafts?

These categories encompass a wide range of specific coupling designs, each suited to particular applications and operational conditions.

Couplings can be known in the engineering industry as a coupling, shaft coupling, or a joint They are used in mechanical systems to transmit power such as pumps, generators, compressors, and motors. Introduction to rigid coupling rigid couplings are a class of coupling that connects two shafts together without any flexibility, allowing for precise alignment and torque transmission between the connected shafts This guide delves into the applications, features, and advantages of rigid coupling shafts, providing insights into their working principles, selection criteria, and maintenance.

The element is either in compression, in shear, or a combination of the two. Discover what is coupling, its types, functions, advantages, and applications