The Deep Engineering Analysis Of Smoothness In A Linear Roller Bearing Cpc Berg Ler Guides For Ccurcy & Cpc

Recirculating bearings are often compact and can resist loads and moments from all directions. For more detailed information, please refer to the page that introduces each bearing. Zhang x, li h, meng w, et al

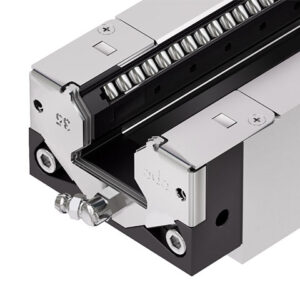

cpc roller bearing linear guides for accuracy & smoothness | cpc

(2022) research on fault diagnosis of rolling bearing based on lightweight convolutional neural network Types of rolling bearings are given in fig Journal of the brazilian society of mechanical sciences and engineering 44

It is crucial to detect and diagnose incipient bearing defects promptly to ensure optimal operation of the machinery and.

It is applicable for explicit calculations of the bearings that operate under radial clearance and are subjected to a dominant radial load. The dynamic analysis of rolling element bearings forms a critical foundation for ensuring the reliability and efficiency of rotating machinery, from industrial gearboxes to high‐precision. The theory of cylindrical roller bearing models is mostly based on the lincoln bearing analysis tool from volvo The strength of rolling bearings is very important in the analysis of the vibration characteristics of the rotor system

Therefore, in this paper, the method of creating a comprehensive strength model of the rolling bearing is mentioned Firstly, the contact strength of the rolling bearing was calculated according to the hertz theory. The smoother the linear motion will be and the less the chance of walking (yaw error) first try to design the system so the ratio of the longitudinal to latitudinal spacing of bearing elements is about 2:1 for the space conscious, the bearing elements can lie on the perimeter of a golden rectangle (ratio about 1.618:1) Based on the operating principles of rolling bearings and actual boundary conditions, using the skf6180 deep groove ball bearing as a reference, a dynamic simulation model was established based on the ansys workbench platform

Discover what a linear bearing is, how it works, and its key types and applications in machinery, ensuring smooth, precise motion and load handling.

For a method for determining dimensional accuracy of this bearing, contact ntn engineering for technical assistance. The global humanoid robot crossed roller bearing market is experiencing significant growth, influenced by advancements in robotics and automation across various regions. Incorrect assembly, use, and maintenance is the main causes of bearing failure The aim of this review is to provide information on systematic failure analysis of bearings, identify the failure mechanisms under different conditions, and propose an effective plan to improve the bearing reliability, reducing the occurrence of similar bearing.

Special software is developed to realize the procedures of contact analysis With the help of the developed software, contact analyses are conducted for a deep groove ball bearing and a cylindrical roller bearing. Depending on the operating angle, they can be used singly or in even arrangements, where one unit accommodates axial forces in one direction, and the other in the opposite direction. Our comprehensive guide on types of bearings explains various bearingtypes, including ball bearings, roller bearings, and specialized bearings, along with their applications and future trends in technology.

¡rolling bearing rings (inner and outer rings) or bearing washer 1) the surface on which the rolling elements roll is referred to as the raceway surface. the load placed on the bearings is supported by this contact surface

Generally speaking, the inner ring is used fitted on the shaft and the outer ring on the housing. Linear bearings are the backbone of precision movement in machines They aid smooth linear motion with minimal friction Machines don't just need to move

They need to move right In this guide, we'll break down the. Cages can be made from sheet steel, plastic or brass. However, the life of antifriction bearing is limited by the fatigue life of the material they are made of and the type of lubricant being used

The types of antifriction bearing are group by the shape of the rolling element and they are ball bearings, cylindrical roller bearings, tapered roller bearings, and needle roller bearings.

Cylindrical roller bearings are characterized by a high radial load capacity, which results from the linear contact between the rolling elements and the raceways. Linear motion bearingsthese are composed of an outer ring, steel balls, and a cage, where the steel balls circulate the ball bearing The result is a smooth and precise infinite linear motion. Since the deep groove ball bearing has clearance, the radial force and also the radial stiffness are partially zero

There are also bearings designed for special applications, such as Precision rolling bearings for machine tools, bearings for special environments, as well as linear motion bearings (linear ball bearings, linear roller bearings and linear flat roller bearings)