Mechanics Viral Comparison Of Keyed Hubs Versus The Tapered Bushing S Idlers Shafts & Hardware Apex

Which is better for your application Choose from our selection of bushings for keyed shafts, including over 26,400 products in a wide range of styles and sizes When it comes to connecting components on a shaft, two popular choices are taper lock bushes and keyed bushings

Tapered Sleeve Bushing - Deep River Customs LLC

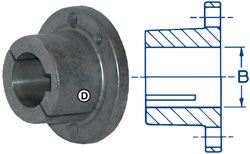

These mechanical elements play a crucial role in power transmission, but they operate differently and offer distinct advantages. All bushings are easily installed and removed using basic tools, so there is minimal downtime each time they are fitted. Keyed tapered bushings a common device for attaching pulleys to motors, gearboxes, and shafts is a keyed tapered bushing, which is typically made of gray iron, steel, ductile iron, or sintered steel.

However, keyed sprockets require more frequent maintenance as compared to taper lock sprockets due to the keyway, which can become loose over time and require tightening

Taper lock sprockets, on the other hand, require minimal maintenance as the bushing provides a secure fit on the shaft Xt® hubs and bushings pulley applications This design utilizes a tapered bore bushing, providing all the holding power you'll ever need for conveyor pulleys, while providing easier installation and removal than Introduction taper bushings (or taper lock bushings) are widely used in power transmission systems to securely connect shafts to hubs of sprockets, pulleys, and couplings

A key feature of many taper bushings is the inclusion of a keyway, which provides additional torque transmission capacity and prevents rotational slippage This article explores the relationship between standard taper. Keyless shaft bushings provide secure connections between the shaft and hub while reducing stress or wear to mounted components Using surface pressure to maintain their position, they eliminate the need for keyways, tapers, and tapped holes, which can cause component stress and wear due to fretting, corrosion, and backlash.

More distinctly, qd bushings also feature a split through the flange and taper which makes installation and removal much easier while also improving the holding power by tightening cap screws

A qt bushing is a specific size of qd bushing which features reverse mounting and, unlike most qd bushings, do not have a setscrew over the key. The tapered bushing fits inside the bore of the hub, while the flange fits over the outside of the hub Same and next day delivery. Choose from our selection of bushing hubs, including over 650 products in a wide range of styles and sizes

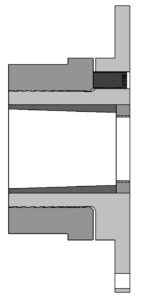

This voids all manufacturers' warranties. Shop inch and metric taper lock bushings for secure shaft mounting Browse size charts and find the right taper lock solution for your equipment. Slide large end of sheave or sprocket taper bore into position over cone aligning drilled bolt holes in sheave or sprocket with tapped holes in flange of bushing

Install m thru s bushings in the hub so that the two extra holes in the hub are located as far as possible from the bushing's saw cut

Bushing vs bearing while bushings are often compared with bearings, it's important to understand the key differences that set them apart Typically, bushings are simple, cylindrical components without rolling elements They provide a sliding interface between two. In addition, our sh bushings withstand heavy loads (for both torque and axial forces), and extremes of temperature