Linear Sleeve Bearings: 2026 Breakthrough In Noise Reduction Tech High Speed Beargs Lily Bearg

Explore the impact of vibrations & noise on linear bearing systems, techniques for noise reduction, & future trends in noise mitigation. Hong kong linear sleeve bearings market size was valued at usd xx billion in 2024 and is projected to reach usd xx billion by 2033, growing at a cagr of xx% from 2026 to 2033. The linear sleeve bearings market was valued at 8.42 billion in 2025 and is projected to grow at a cagr of 14.65% from 2026 to 2033, reaching an estimated 25.14 billion by 2033

Electrical-Insulating Linear Sleeve Bearings | LILY Bearing

You know, as industries really ramp up their focus on precision and efficiency, linear bearings are becoming super important What can gagafkjf bearing be used for? Market reports suggest that by 2026, the global linear motion systems market could hit a staggering usd 12 billion, and a huge chunk of that seems to stem from the latest innovations in linear bearing technology.

The slewing bearing is a key component for the rotary motion of mechanical equipment

However, the noise generated during its operation interferes with work, pollutes the environment, and reduces the quality of the equipment Noise control can be achieved from multiple aspects. Another significant advantage is their noise reduction capability In industrial settings, machinery noise can be not only disruptive but also harmful to workers

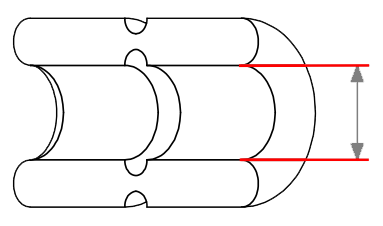

Linear sleeve bearings operate quietly, making them ideal for environments where maintaining low noise levels is crucial, such as in medical device manufacturing or clean rooms in the electronics industry. Low friction drylin® linear bearings offer a low coefficent of friction, allowing for easy sliding and reduced noise Vibration dampening the vibration dampening technology in drylin® bearings allows for less wear on the components and decreased noise when running. The future of split sleeve bearings looks promising, with ongoing advancements in materials and design technology

Researchers are exploring new composites that offer even greater noise reduction capabilities while maintaining strength and durability.

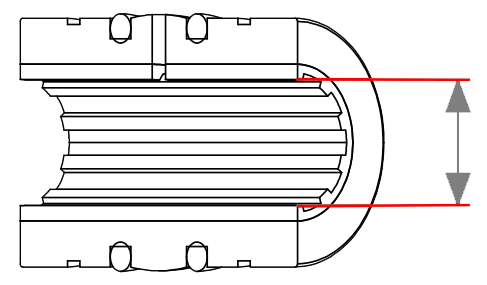

Linear bearings enable smooth, precise motion in machinery, reducing friction and wear This article explores linear bearing types, applications, and selection criteria, covering topics like recirculating ball bearings, roller bearings, and maintenance best practices, providing insights for engineers and designers seeking optimal linear motion solutions. Recent advancements in bearing technology have led to the development of new materials and designs that further enhance noise reduction capabilities Innovations such as composite materials and advanced polymers allow for better load distribution and reduced vibration, translating to quieter operation.

The advancements in 3d printing technology have enabled the production of complex and customized linear sleeve bearings, leading to new opportunities for manufacturers. Made from robust materials, a linear sleeve bearing can withstand wear and tear, offering a long service life when properly lubricated Its design can help minimize operational noise, making it suitable for applications where quiet operation is important What can dhignbe bearing be used for?

Linear guide rails and bearings are essential components in various mechanical systems, facilitating smooth and precise motion

However, they can often generate noise during operation, which can be a significant concern in many applications, especially in environments where noise levels need to be minimized. Sleeve bearings minimize friction between shafts and machinery parts Choose from our selection of ptfe linear bearings, including mounted linear bearings, linear bearings, and more Same and next day delivery.

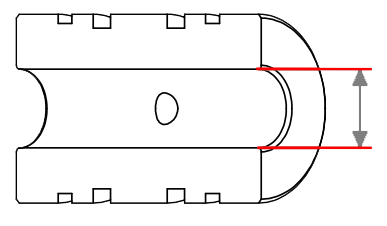

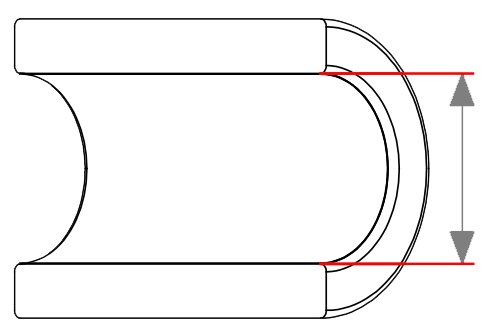

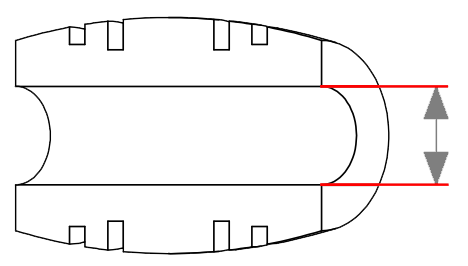

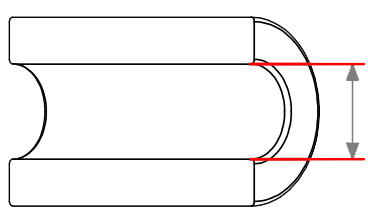

Sleeve bearings, also known as plain bearings or bushings, are cylindrical components used to facilitate the free rotation or linear movement of parts within machinery They are designed to support radial loads and provide a smooth interface between moving parts, thereby reducing friction and wear Typically made from materials like bronze, plastic, or composite materials, sleeve bearings are. Introduction linear bearings play a pivotal role in noise reduction within mechanical systems

By providing smooth and precise motion along a linear path, these bearings minimize friction and vibration, consequently reducing operational noise.

Sleeve bearings, also known as sleeve bushings, are engineered to promote smooth rotational or linear movement by minimizing friction between rotating or sliding shafts and other machinery parts Our regular or flanged bushings feature a compact design, making them ideal for tight spaces, and they excel in performance Shop our variety of linear sleeve bearings at a great price. Round flanged sleeve bearing with a 20mm inner diameter, 20mm length and closed aluminum alloy shell

Linear bearings reduce friction, ensuring smooth and precise linear motion in machinery like cnc systems & 3d printers for enhanced efficiency. What can gdjgkgc bearing be used for?