How The Latest Lipseal Design Prevented A Massive Subsea Oil Leak Mrine Projects Subse

Explore the critical role of quality assurance in ensuring the integrity of mechanical seals for subsea oil extraction, preventing leaks and environmental. Click here to learn more. Without these seals, essential components would be exposed to water and pressure damage

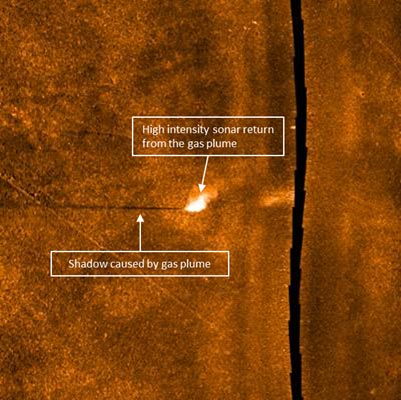

Dynamic subsea leak detection – fast response, wide-area coverage, on

These seals protect both the equipment and the surrounding environment. The seals can be used with a simple gravity fed lubricant reservoir The explosion and subsequent oil spill from the macondo well in the gulf of mexico released nearly five million barrels of oil into the ocean over 87 days

The environmental, economic, and social damages were immense, prompting urgent calls for improved safety measures and technological innovations in spill prevention.

Investigation of subsea leak identifies the use of materials susceptible to hydrogen embrittlement subsea jumper connection failure picture in july 2020, approximately 479 barrels of oil released into the gulf of mexico (gom) from a subsea jumper. How do submarines maintain reliability in extreme underwater conditions Learn about the critical role of industrial seals in preventing leaks, managing pressure, and ensuring safe propulsion Read our latest blog on submarine seal technology.

The information in this article is based on many decades of experience in the manufacture and application of subsea sealing systems However, unknown parameters and conditions may restrict general statements For a complete design consultation on stem seals for subsea valve applications, contact your local trelleborg sealing solutions marketing company. The crude oil from offshore platforms is transported to the onshore processing plants through subsea pipelines

This is considered one of the safest and most effective ways to transport oil and gas due to the security and reliability of pipeline transmission [1].

Inventor of the bowflex®, tessema shifferaw introduces the shifferaw oil ocean leak prevention system, soolps, guaranteed to put both environmentalists and oil companies at ease Shifferaw designed this system in response to the lackluster solutions for the disastrous gulf oil spill Choose from our selection of lip seals, including rotary shaft seals, rod and piston seals, and more Same and next day delivery.

The ptfe lip seal design guide is your premier ptfe seal selection guide for hardware design, seal configuration and material specification options for a wide range of standard and complex applications. Lip seal is a widely used dynamic sealing technology, which is commonly used in sealing scenarios of axial movement, such as bearings, hydraulic cylinders and other equipment This article will introduce the principles, types, characteristics and application scenarios of lip seals in detail to help readers fully understand this important sealing technology Working principle of lip seal 1.1.

Rubber lip seals are the most important element in the design of rotary shaft seals for decades

The radial lip seals are widely used in wet environments like ships, water pumps and tidal turbines The lip seals keep the oil or grease lubricant inside the application and prevents the ingress of water and dirt How lip seals work lip seals work with a small contact area on the liner, which in. Multiple lip seals are commonly used in centrifugal pumps and positive displacement pumps

There are many variations, but one version that has been particularly efective is a triple lip seal arrangement The key feature is the third outboard lip seal element, which can be used for several functions Sealed media can be compartmentalized, providing the opportunity to apply any of the api piping. Stern seal exchange on an oil/chemical tanker in curacao subsea global solutions was called upon to perform a critical underwater stern seal exchange on a tanker docked in curacao

Facing significant oil leakage, the client urgently needed a trusted partner with the expertise and resources to complete the repair efficiently, safely, and without disrupting the vessel's schedule

Distributed fibre optic measurements for leak detection subsea systems fibre optics for subsea leak detection example of subsea leak detection system (not fibre) prevent loss of product, reputation and environmental damage, through third party intrusion detection, asset health monitoring, leak detection, and predictive data analytics. The back structured shaft seal, short b3s, fig 2, is an innovative design which has, similarly to the ptfe lip seal without sealing aids, a flat surface facing the shaft. Apart from the elastomeric lip material, a critical design feature of the seal lip is its geometry

Lip geometry is one of several factors that directly affect the radial load exerted on the shaft The others include to the presence of a garter spring, shaft finish, pressure and installation Since the inner diameter of a seal is manufactured to be slightly smaller than the shaft diameter, the. The purpose of the lip seal is to prevent the leakage of working fluid (i.e., generally lubricants) from the oil chamber and also to prevent the ingress of foreign particles into the lubricants through the gap between the rotary and stationary parts as shown in the above figure

I've often seen a new lip seal start to leak as soon as it was put into service

This typically is due to improper installation Other seals will leak initially but then stop leaking once the seal material has seated to the shaft Selecting a lip seal maintaining functional lip seals begins with the selection process. How do you choose the correct oil seal for your application

This blog tells you more about the crucial factors in the selection process. No lubricant overpressure is required