How Tapered Bushing Designs Are Reducing Assembly Time By 30 Percent Installation American Precision

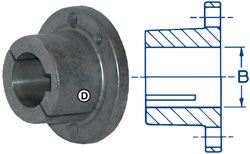

This eliminates the need for complex assembly procedures, specialized machining, or precision taper fitting keys, substantially reducing installation time and costly factory downtime. They feature a tapered surface that matches the taper on the hub of the mounted component. Taper bushings are designed for easy assembly and disassembly, reducing downtime and maintenance effort

24mm Tapered Bushing, Metric - Dultmeier Sales

The tapered design ensures a tight grip between the shaft and the mounted component, minimizing slippage. Unlike solid bushings, split taper bushings have a split design, allowing for easy installation and removal Taper lock bushes are specially designed mechanical components that provide a secure and precise method of mounting pulleys, sprockets, and couplings onto shafts

On to shafts only using a hexagon wrench

Their design allows for quick installation and removal, reducing the time and labour costs associated with maintenance and repairs Additionally, because they provide a secure and reliable connection, the risk of damage to other components is minimised, leading to lower replacement costs over time. Tapered bushings support the operation of heavy machinery by attaching to shafts Also called taper bushings, they have diameters that gradually decrease

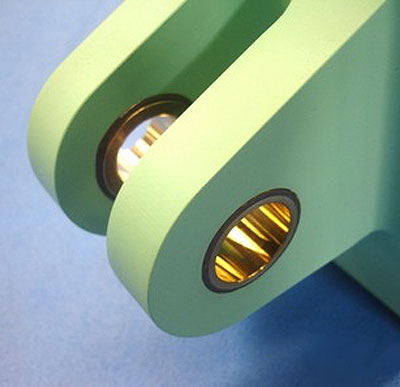

This reduces friction between two surfaces Tapered bushings are typically cylinders, and the tapered area can be internal or external. As the name suggests, these couplings utilize a tapered hub and tapered bushing arrangement to achieve a secure and reliable connection The tapered surfaces of both the hub and bushing allow for easy assembly and disassembly without the need for additional keys or set screws.

Additionally, because they provide a secure and reliable connection, the risk of damage to other components is minimized, leading to lower replacement costs over time.

Its tapered design ensures an even distribution of stress, minimizing wear and maximizing the lifespan of both the bushing and the attached components Some of the most common types include Cylindrical bushings used for linear motion applications Bushings with a flange on one end to aid in mounting and prevent axial movement

Designed to support axial loads and used in rotating machinery. This tapered bushing assembly is specifically crafted for speed reducers, offering a reliable solution for reducing rotational speed while maintaining torque and efficiency. Patented twin taper bushing systems twin tapered bushing system eliminates fretting corrosion and reducer wobble and can be installed with regular hand tools standard twin taper bushing system for full length shafts short shaft bushing system to replace straight bore The good thing about the split tapered bushing could it be will hold, even if the fasteners become loose

Split tapered bushings are interchangeable between manufacturers

Their design allows for quick installation and removal, reducing the time and labour costs associated with maintenance and repairs. Speed reducer bushing kit the dodge 272080 4 15/16 tdt9 tapered bush assembly is a premium component designed specifically to enhance the performance and efficiency of speed reducers. Same and next day delivery. This speed reducer bushing kit is engineered to provide optimal performance and reliability, ensuring effective power transmission for various machinery and equipment.

Speed reducer bushing kit the dodge 2 15/16 tdt8 tapered bush assembly is a premium speed reducer bushing kit designed to enhance the performance and reliability of industrial machinery. Five flute is a continuous design review platform that helps modern engineering teams share, review and improve their engineering designs. What are the split taper bushings Split taper bushings are mechanical components used for mounting pulleys, sprockets, and other devices onto shafts