How A Single Industrial Pulley Failure Grounded A Major Port Operation Probbility Of Filure Free Opertion Of Locomotive Diesel Engines

As such, significant research has gone into the appropriate safety measures and procedures for ship movements in and out of port hedland Contribute to looktooz/rimeconfig development by creating an account on github. Port hedland is the largest bulk export port in the world, and a grounding in the channel could have significant outcomes not only for the environment and for the safety of those on board, but.

Single Pulley Systems Do More How To Tie A Rope And Knots #diy #tie

This was most probably due to prolonged operation with an unbalanced impeller and oversized bearing housing, aggravated by varying engine load due to the ship's rolling and pitching Dive into the five key causes of crane failure, learn their root issues, and uncover practical preventive strategies for enhanced crane safety and reliability. The failure of auxiliary blower number 2 substantially reduced the normal airflow to the engine.

Poor bridge team management was identified as having been the root cause of the grounding

Bulk carrier grounded by short circuit atsb (australian safety transport bureau) investigated an electrical short circuit that grounded a bulk carrier Our client's port operations, located in west australia, had ramped up operations significantly in just a few years With the business now operating in a stable environment, the focus turned to equipment and process optimisation In this instance an electrical short circuit led to the loss of power to all of the ship's analogue rudder angle indicators. the atsb's.

Human errors mostly cause ship grounding accidents, sometimes by inadequate information related to the port access route or the seabed Also, improper maneuvering and navigational operations are common causes for unintentional ship grounding. A blocked port approach channel will in most cases be devastating for the port and its operators Besides knowing how and when it is safe to pass the grounded ship, the port can develop emergency procedures for how to operate the port in case a ship is grounded in the approach channel.

Troubleshooting refrigeration systems learn with flashcards, games, and more — for free.

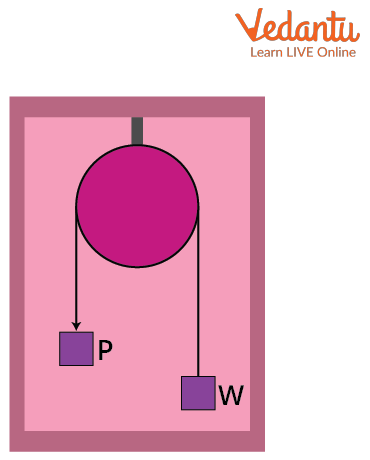

Techniques for pump failure diagnosis and prevention effective pump failure management requires both diagnostic and preventive techniques Diagnostic methods help identify the root cause of failures, while preventive techniques focus on monitoring performance trends to detect early warning signs before a breakdown occurs. Understanding the different parts of a pulley system is essential for its proper operation and maintenance The pulley itself is the main component of the system.

However, like any mechanical system, ahus are susceptible to various issues that can affect their performance Let's explore common problems encountered in air handling units and provide insights into troubleshooting to keep these crucial. At its essence, an industrial pulley is a wheel on an axle or shaft designed to support the movement and change the direction of a force through a rope or belt. How to find your router's ip address how to forward ports ports to forward for grounded forward ports for grounded when you are playing grounded you might need to forward some ports in your router

Forwarding ports is a useful trick in gaming because it can really help to make your network connection most stable and intermittently even faster.

Discover the types of pulley and other mechanical devices, how to choose the right pulley, and best practices for maintenance. Through proper installation and maintenance, the service life of your belt drives will dramatically improve — reducing downtime and production standstills. Every six months, 1,800 operating hours or 50,000 miles, whichever occurs first, check for noisy compressor operation, which could indicate a worn drive gear coupling, a loose pulley or excessive internal wear. Overhead cranes are essential equipment widely used in industrial production and material handling

However, as the frequency of usage rises and operating environments become more diverse to meet modern industrial demands, failures and challenges have become increasingly common This makes overhead crane troubleshooting a critical focus for ensuring reliable performance in various industries.