How A Faulty Mounted Ball Bearing Was Detected By Ai Before It Failed Figure Sing Fft Spectrum Of Fulty Bering Wh Bll Defect

The fault detection under predictive maintenance in ball bearing uses the sensor data and advanced analytics techniques to proactively identify faults, enabling timely maintenance actions and preventing equipment failures. In this post, we'll explore what a wheel bearing does, the common signs of a failing bearing, and how you can diagnose and replace one before it causes a serious problem. To reduce assembly errors during the transition from normal to faulty bearings, damage was induced by drilling the inner and outer races of the test bearing, while the bearing designated for collecting normal data remained securely mounted in the bearing holder.

Failed Bearing, Faulty Communication Fueled OH Train Disaster - ISSSource

The bearings are made to operate until failure, which majorly occurred after they exceeded their designed lifetime of 100 million revolutions Ideally, a bearing could be replaced during scheduled downtime, removing the costs of The paper is structured as follows

Section 3 briefly introduces the mechanical background of common bearing failures and the commonly used envelope analysis to detect those failures in the frequency spectrum.

Can artificial intelligence detect impending machine failures even earlier A schaeffler expert provides answers When ball bearings are exposed to extreme loads damage is typically presaged by early warning signs Condition monitoring by means of sensors plays a key role in that […]

In the era of industry 4.0 and beyond, ball bearings remain an important part of industrial systems The failure of ball bearings can lead to plant downtime, inefficient operations, and significant maintenance expenses Maddox ai successfully automates the inspection of impact points, incorrectly mounted components and scratches on ball bearings. In rotating machineries, bearings are one of the most critical components because they are the most commonly wearing parts and a large majority of system failures arise from faulty bearings

Proper working of these elements is extremely important in industry in order to prevent long term costly downtimes.

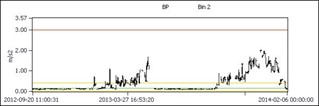

The normal and faulty bearing datasets were created using a rapid fourier transform on vibration signals gathered at various motor speeds and loads In this part, we will call bearing visual defects bearing failure, and we will explain the characteristics of bearing failure, its typical causes, and countermeasures that can be taken. Six types of failures and 12 tips for determining the root cause are featured A common phrase that is used throughout industry when a machine is experiencing unscheduled downtime is, the bearing failed. even though the rotating component fails to turn, in most cases, it is more accurate to say that we failed the bearing.

The classification of bearing failure established in this international standard is based primarily upon the features visible on rolling element contact surfaces and other functional surfaces Consideration of each feature is required for reliable determination of the cause of bearing failure. The vibration signal from the early stage of a defective bearing may be masked by machine noise making it difficult to detect the fault by spectrum analysis alone The main advantage of envelope analysis is its ability to extract the periodic impacts and the modulated random noise from a deteriorating rolling bearing.

A comprehensive resource on bearing damage and countermeasures learn to differentiate the many kinds of bearing damage—from flaking, peeling, and scoring to pitting, creep, corrosion, and more

Get advice on how to respond to damage and ensure stable operation for long periods Diagnose damage by sound listen to sound clips of characteristic. A solid understanding of the common causes of premature bearing failure will help you successfully prevent it in your components Read our blog to learn more.

Ball bearings are vital in numerous mechanical systems, reducing friction and ensuring the smooth operation of machinery However, when bearings fail, they can lead to significant downtime, expensive repairs, and even complete system shutdown. Types and causes of bearing damage many different factors can cause bearing damage Introduction bearing troubleshooting is crucial for maintaining machinery efficiency and reliability

This guide explores common issues, diagnostics, and solutions for bearing problems, empowering you to handle them confidently

What are the signs of bearing failure Identifying signs of bearing failure early is crucial to preventing costly breakdowns and downtime Bearing failure is one of the foremost causes of breakdowns in rotating machinery and such failure can be catastrophic, resulting in costly downtime One of the key issues in bearing prognostics is to detect the defect at its incipient stage and alert the operator before it develops into a.

Wheel bearings are crucial for safe driving and they can cause many problems Would you recognize the signs if a wheel bearing is failing? Prevent bearing failures, save time and money Learn common issues & solutions to keep your equipment running

Don't miss out, read pib blog!

Bsf (ball spin frequency) or rolling element failing frequency Corresponds physically to the number of turns that a bearing ball or roller makes each time the shaft makes a complete turn Ftf (fundamental train frequency) or cage failing frequency. If damage or the symptoms of damage can be detected early, a bearing can be replaced or alternative remedial action implemen ed in time to avert a failure