Future Electric Delivery Vans To Utilize Noise-dampening Spider Couplings Coupling Hwl Group

The microlino spider reimagines micromobility with its iconic yet innovative design Due to the special spring and damping properties of the profiled coupling sleeves, elco effectively limits torsional vibrations. As cities continue to expand and demand for green solutions grows, rivian's role becomes even more critical.

Amazon's new custom Rivian electric delivery vans are hitting the road

The electric van segment in the united states is witnessing increased attention thanks to new launches from startups and established brands. The torsionally resilient, flexible coupling is responsible for effectively dampening the shocks and vibrations that occur in drive systems during operation Everything you need to know about amazon's electric delivery vans from rivian amazon is committed to decarbonizing its delivery fleet and has rolled out more than 25,000 custom electric delivery vans across the u.s.

In 2024, several electric delivery vans and trucks stand out for their innovative designs, impressive performance, and overall value

In this blog, we'll explore some of the best electric delivery vans and trucks currently available, making it easier for businesses to transition to electric solutions. Amazon has over a thousand rivian edv electric delivery vans on the road Here's a look at how they're doing and what the future holds. Electric delivery vans are the future of urban logistics

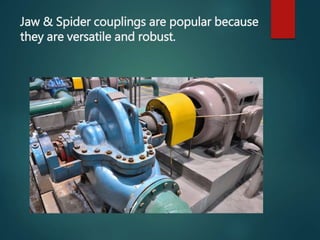

Our guide explains the powerful economic reasons why amazon, fedex, & ups are making the switch now. Future trends in jaw coupling spider technology advancements in materials science and manufacturing processes are driving continuous innovation in jaw coupling spider technology. Types of shaft coupling, its uses, drawings, and applications, and more also download the pdf file of this article. Spiders are key to jaw coupling performance one of the most widely applied types of flexible couplings is an elastomeric design known as the jaw coupling

This design is characterised by two hubs, each having two or more thick, stubby protrusions around their perimeters, called jaws, pointing toward the opposing hub.

In summary, spider couplings offer significant advantages over other couplings, including high torque transmission capacity, misalignment compensation, vibration damping, ease of installation and maintenance, and versatility in various applications. Choose from our selection of lovejoy couplings, including set screw flexible shaft couplings, clamping flexible shaft couplings, and more Same and next day delivery. Explore the intricate world of jaw couplings and uncover the significance of rubber spider for jaw coupling in this comprehensive guide

Learn about the composition, functionality, advantages, and maintenance of rubber spiders, as well as considerations for selecting the right one for your application Discover why rubber spiders stand out in vibration dampening, misalignment compensation, and. These spiders provide flexibility and damping properties, making jaw couplings suitable for applications requiring shock absorption and vibration reduction Components of jaw coupling jaw couplings typically consist of the following components

These hubs connect to the shafts and provide structural support.

By considering factors such as torque capacity, misalignment compensation, damping characteristics, operating environment, and backlash, engineers can develop optimized spider coupling designs for various applications The versatility and advantages of spider coupling design make it a popular choice in numerous industries The spider jaw type coupling's shape and material reduce reaction loads resulting from misalignment Choose from our selection of misalignment couplings, including precision flexible shaft couplings, flexible shaft couplings, and more

High damping performance rubber coupling for servo motors and stepping motors The newly developed rubber element achieves high damping and low reaction force It absorbs vibrations more quickly than flexible couplings that use metal for their elastic parts This suppresses the resonance phenomenon that can occur in stepping motors, etc.

Jaw couplings are made up of 3 parts, two metallic hubs and an elastomeric spacing element (also known as a spider) this means depending on your application, these couplings offer different levels of dampening protection.

Power transmission coupling products to replace universal joints, jaw couplings, elastomeric and other couplings Replaces all power transmission couplings.