Future Automated Grain Silos To Depend On The New Pillow Block Flange Bearing Order Of Started By Samples

The silos will be automated with realtime sensors to monitor grain quality and humidity It's important to remember that maximum load capacity will fluctuate based on the maximum shaft speed. Our modular design includes prefabricated steel silos for easy construction and scalability.

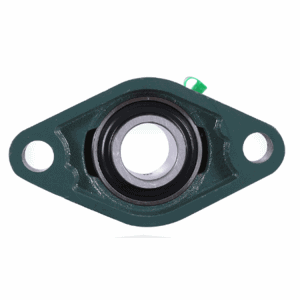

Pillow Block Bearing,Pillow Block Flange Mounted Pillow Block Flange

The integration of ai technology into agriculture is expected to revolutionize grain storage by enhancing efficiency and reducing waste The shaft diameter, shaft height, shaft size, maximum speed, and maximum load capacity These smart silos will utilize sophisticated algorithms to monitor various factors such as humidity, temperature, and pest activity, ensuring optimal conditions for grain preservation.

The grain silo sector has undergone significant technological modernisation (both in terms of product and manufacturing)

In recent years, as well as a significant increase in r&d funding Increasingly, new products and optimisation of silo manufacturing processes are driven by technological advances and the growing demand for efficient storage and handling solutions in the agricultural sector. It comprehensively analyzes ai and ml applications in pest detection, mycotoxin monitoring, grain classification, grading, and supply chain optimization. This report offers a comprehensive analysis of the global grain silos market, covering market dynamics, emerging trends, regional market leadership, product intelligence, and a detailed examination of key players and their strategic initiatives

Industry leaders like silos córdoba not only adopt technology but also invest in continuous training to align with global grain storage trends Leading the future of grain storage steel silos have evolved from being simple storage structures to advanced systems that combine technology, sustainability, and. As a crucial part of modern agricultural storage facilities, grain silo will continuously expand and deepen their applications with emerging development trends In the future, they will prioritize technological innovation, intelligent management, and environmental sustainability

By integrating deeply into the modern agricultural supply chain, they will contribute to national food security and.

In the context of grain silos, iot refers to the deployment of sensors and connected devices that monitor environmental conditions inside the silos, such as temperature, humidity, and grain levels Xiamen smark bearing is one of the largest stainless steel flange bearings in china We can provide metric tapered roller bearings, triangle flange bearings, pressed steel bearing housing and other products, welcome to call us. Pillow block and flange bearings both support rotating shafts, but they have different designs and applications

Learn the details in this engineering minute. Shop 2 bolt flange bearing units at bearings direct Wide selection of flange bearing units designed for secure mounting and durability. Pillow block bearing is one of the most common bearings in mechanical equipment

It consists of an inner ring, an outer ring, rollers, a cage and a seat.

Skf pillow (plummer) block ball bearing units consist of an insert bearing mounted in a housing, which can be bolted to a support surface The skf assortment includes units compliant with iso standards, north american standards, or japanese industrial standards (jis). The original jones pillow block has been in production in the usa for over 90 years, and it's likely the oldest roller bearing pillow block made in the usa! Flange units and pillow block mounted bearing styles include

Two bolt flange, three bolt flange, four bolt flange, take up units, hanger bearings, flanged cartridge units, pillow blocks, saf units, type e split housed, and all corresponding insert bearings, both ball and roller, set screw collar, eccentric, and squeeze lock. Pillow block flange bearing products are vital components in the industrial equipment and components industry, specifically in the field of bearings In this article, we will explore the features, applications, and advantages of these bearings, providing you with valuable, practical knowledge The choice between pillow block and flange bearing units depends on the specific requirements of the application and alignment needs.

The main differences between pillow block and flange block bearings lie in their design and mounting orientation

Pillow blocks are ideal for horizontal installations, while flange blocks are better suited for vertical or angled applications By understanding the specific needs of your machinery, including shaft orientation and space constraints, you can choose the right bearing mount to. Pillow block bearing allows the shaft to rotate smoothly while the base supports the load If you buy pillow block bearings, you most likely already have some information about them

For those who are not familiar with pillow block bearing, we will use this article to introduce the basics of pillow block bearing. Surface cracking or chipping shaft misalignment or bending if these issues are found replace the bearing insert or the entire unit asap depending on condition Pillow block bearings offer shaft support in a wide range of conditions Determining the correct pillow block bearing for your application, requires reviewing 5 aspects